Reinforced saline soil with wheat straw and solidifying method thereof

A solidification method and technology of wheat straw, applied in the fields of soil protection, construction, infrastructure engineering, etc., can solve the problems of irreversible environmental pollution, increased construction cost, high construction cost, etc., achieve good solidification effect, reduce construction cost, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

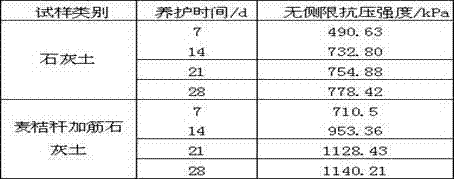

[0034] A kind of wheat straw reinforced saline soil, which is characterized in that fiber reinforced material wheat straw is added to the saline soil, the surface of the wheat straw is attached with polyvinyl alcohol film, the length of the wheat straw is 5-15mm, and the length of the wheat straw is 5-15 mm. The mass reinforcement rate is 0.25%; lime is added to the saline soil, and the mass content of lime is 8%.

Embodiment 2

[0036] A method for solidifying wheat straw reinforced saline soil, the construction steps are:

[0037] 1. Antiseptic treatment of wheat straw: air-dry and cut off the harvested wheat straw, soak the wheat straw for 2 days, and air-dry the wheat straw for 2 days after soaking;

[0038] 2. Reinforcement and curing of saline soil: Stir the soaked wheat straw with a length of 5-15 mm, with a reinforcement rate of 0.25% and lime with a mass content of 8%, and mix it with saline soil for uniform curing. The construction and maintenance time is 28 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com