Electromagnetic weft insertion weft carrier, rapier for electromagnetic weft insertion as well as electromagnetic weft insertion method

A weft carrier and weft insertion technology, applied in the field of electromagnetic weft insertion weft carrier, rapier for electromagnetic weft insertion and electromagnetic weft insertion, can solve the problems of reducing the service life of shuttles, flying off the shed, reducing the success rate of weft insertion and Weaving efficiency and other issues to achieve the effect of increased life, easy operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

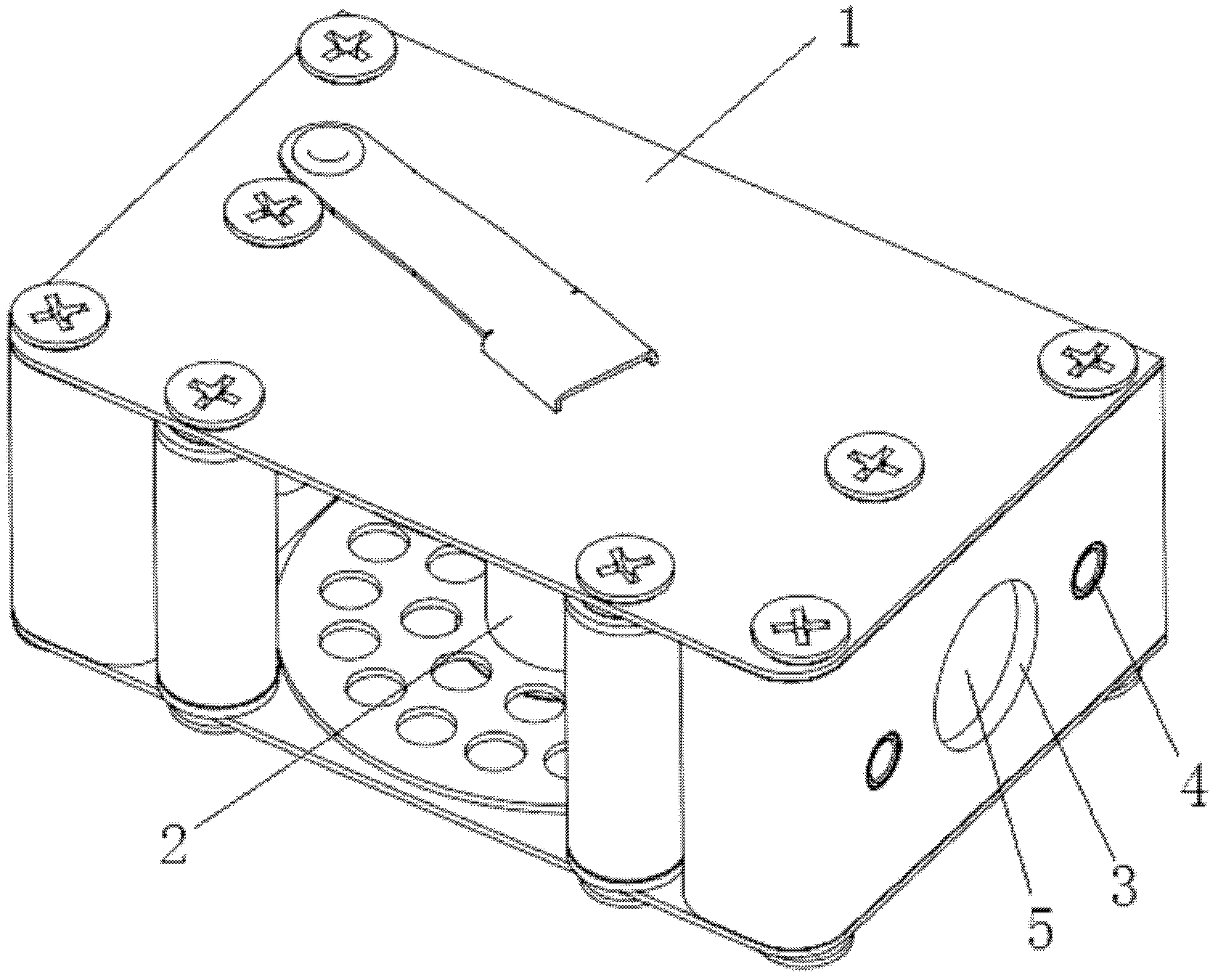

[0025] Such as figure 1 As shown, it is the electromagnetic weft insertion carrier of the present invention, which includes a shuttle box 1 and a yarn storage device 2 located in the shuttle box 1, and the corresponding two side walls of the shuttle box 1 are respectively provided with a wire for electromagnetic weft insertion. permanent magnet 5 and two positioning holes 4. The inner wall of the positioning hole 4 is provided with a copper sleeve for preventing the positioning hole from being worn and affecting the positioning effect. The cross section of the positioning hole 4 is circular. Two corresponding side walls of the shuttle box 1 are respectively provided with an inward counterbore 3 , and a permanent magnet 5 is fixed in the counterbore 3 . The top surface of the permanent magnet 5 is lower than the outer surface of the side wall of the shuttle box 1 . When the section of positioning hole 4 is circular, two positioning holes need to be set, and the weft carrier i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com