Method for smelting chromium-containing cast iron by using vanadium-containing calcium slag

A calcium slag, vanadium-chromium technology, applied in the field of chromium salts, can solve the problems of vanadium resource utilization, difficulty in separation of slag and iron, hexavalent chromium pollution of vanadium-containing calcium slag, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

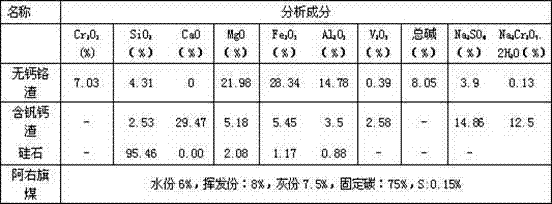

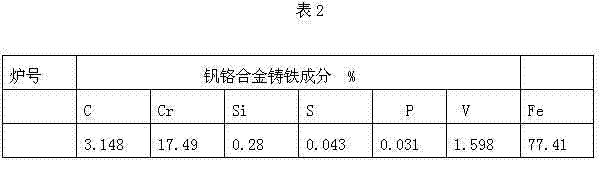

[0021] This example is based on the production statistical data of the 3500KVA electric arc furnace. The furnace material capacity of the 3500KVA electric arc furnace is 10 tons, the diameter of the furnace shell is 5200mm, the height is 3300mm, the diameter of the furnace is 3600mm, and the height is 1600mm; Way. The main chemical components of the raw materials used are calcium-free chromium slag, Xinjiang coal, silica, and vanadium-containing calcium slag as shown in Table 1:

[0022]

[0023] Specific steps are as follows:

[0024] 1. Add 600Kg of vanadium-containing calcium slag to 5000Kg of calcium-free chromium slag, 818Kg of Xinjiang coal with a diameter of 1-3mm, and 240Kg of silica less than 1mm, and mix evenly with a mixer.

[0025] 2. The raw materials that have been uniformly mixed by the mixer are then mixed again by tubular biaxial agitation, and 466Kg water is evenly sprayed on the 6658Kg ingredients at the biaxial agitation outlet to form particles with a ...

Embodiment 2

[0031] This example is based on the production statistical data of the 3500KVA electric arc furnace. The furnace material capacity of the 3500KVA electric arc furnace is 10 tons, the diameter of the furnace shell is 5200mm, the height is 3300mm, the diameter of the furnace is 3600mm, and the height is 1600mm; Way. The raw materials used are calcium-free chromium slag, coke, silica, and vanadium-containing calcium slag. The main chemical components are as follows:

[0032]

[0033] Specific steps are as follows:

[0034] 1. Add 907Kg of vanadium-containing calcium slag, 943Kg of coke with a diameter of 1-3mm, and 239Kg of silica less than 1mm into 5289Kg of calcium-free chromium slag, and mix them evenly with a mixer.

[0035] 2. The raw materials mixed uniformly by the mixer are mixed again by tubular biaxial agitation, and 827Kg water is evenly sprayed on the 7378Kg ingredients at the biaxial agitation outlet to form particles with a diameter of 20mm on the ball formi...

Embodiment 3

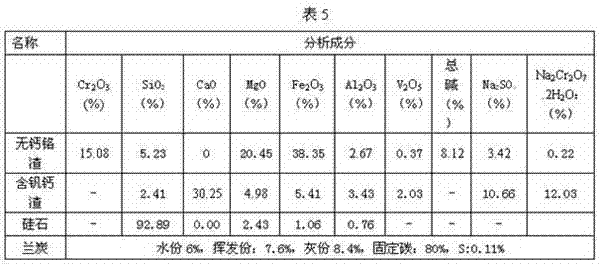

[0042] This example is based on the production statistical data of the 3500KVA electric arc furnace. The furnace material capacity of the 3500KVA electric arc furnace is 10 tons, the diameter of the furnace shell is 5200mm, the height is 3300mm, the diameter of the furnace is 3600mm, and the height is 1600mm; Way. The raw materials used are calcium-free chromium slag, semi-coke, silica, and vanadium-containing calcium slag. The main chemical components are as follows:

[0043]

[0044] Specific steps are as follows:

[0045] 1. Add 540Kg of vanadium-containing calcium slag to 6000Kg of calcium-free chromium slag, 972Kg of blue charcoal with a diameter of 1-3mm, and 337Kg of silica less than 1mm, and mix evenly with a mixer.

[0046] 2. The raw materials that have been uniformly mixed by the mixer are mixed again by tubular biaxial agitation, and 1000Kg water is evenly sprayed on the 8740Kg ingredients at the biaxial agitation outlet to form particles with a diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com