Method for preparing zinc oxide micron sphere

A technology of zinc oxide micron and zinc salt, which is applied in the direction of zinc oxide/zinc hydroxide to achieve the effect of increasing yield and facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

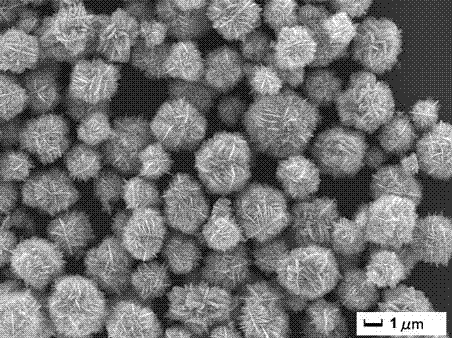

[0020] Weigh a certain amount of NaOH, Zn(NO 3 ) 2 , NH 4 F were respectively dissolved in distilled water; the above solutions were mixed and stirred to obtain a mixed solution; the prepared mixed solution was kept in a water bath at 70°C for 10 hours; Drying at a temperature of 40 ° C can obtain nanosheets to construct ZnO microspheres; by figure 1 As shown, the thickness of the nanosheets is about 20 nm, and the diameter of the zinc oxide microspheres constructed is 1-4 μm. figure 2 For the EDS energy spectrum analysis of the sample, no impurity elements were detected, indicating that the prepared nanosheets to construct ZnO microspheres have high purity.

Embodiment 2

[0022] Weigh a certain amount of NaOH and ZnSO at a molar ratio of 1:0.15:0.6 4 , NH 4 F are respectively dissolved in distilled water; the above solutions are mixed and stirred to obtain a mixed solution; the prepared mixed solution is kept in a water bath at 80°C for 15 hours; Drying at a temperature of 50°C can obtain ZnO microspheres constructed of nanosheets; as image 3 As shown, the thickness of the nanosheets is about 20 nm, and the diameter of the microspheres is about 1.5-4 μm.

Embodiment 3

[0024] Weigh a certain amount of KOH and ZnCl at a molar ratio of 1:0.15:0.6 2 , NH 4 F were respectively dissolved in distilled water; the above solutions were mixed and stirred to obtain a mixed solution; the prepared mixed solution was kept in a water bath at 90°C for 10 hours; Drying at a temperature of 40°C can obtain nanosheets to construct ZnO microspheres; as Figure 4 As shown, the thickness of the nanosheets is about 20 nm, and the diameter of the microspheres is about 1.5-4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com