Pressurization roasting method for carbon

A roasting and carbon technology, applied in the field of carbon roasting technology, can solve the problems of long heating curve, product cracking, cracked waste products, etc., and achieve the effect of reducing cracked waste products, reducing temperature difference, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples will further illustrate the present invention.

[0025] Following embodiment adopts existing carbon ring type roaster, and described carbon pressure roasting method comprises the following steps:

[0026] 1) Place the pressed green product in a sagger, and add calcined petroleum coke between the product and the sagger, the particle size of which is 6-2 mm; the sagger is made of stainless steel; The pipes are connected directly to the outside of the furnace, and vacuum pressure gauges and valves are installed on the seamless pipes extending outside the furnace in sequence; the distance between the wall of the sagger and the product is not less than 100mm.

[0027] 2) Seal the sagger after filling the product, vacuumize, and then fill with nitrogen; the vacuum degree of the vacuum is less than -0.093MPa, and after maintaining for 40min, fill with nitrogen, and the pressure of nitrogen is 1.5MPa.

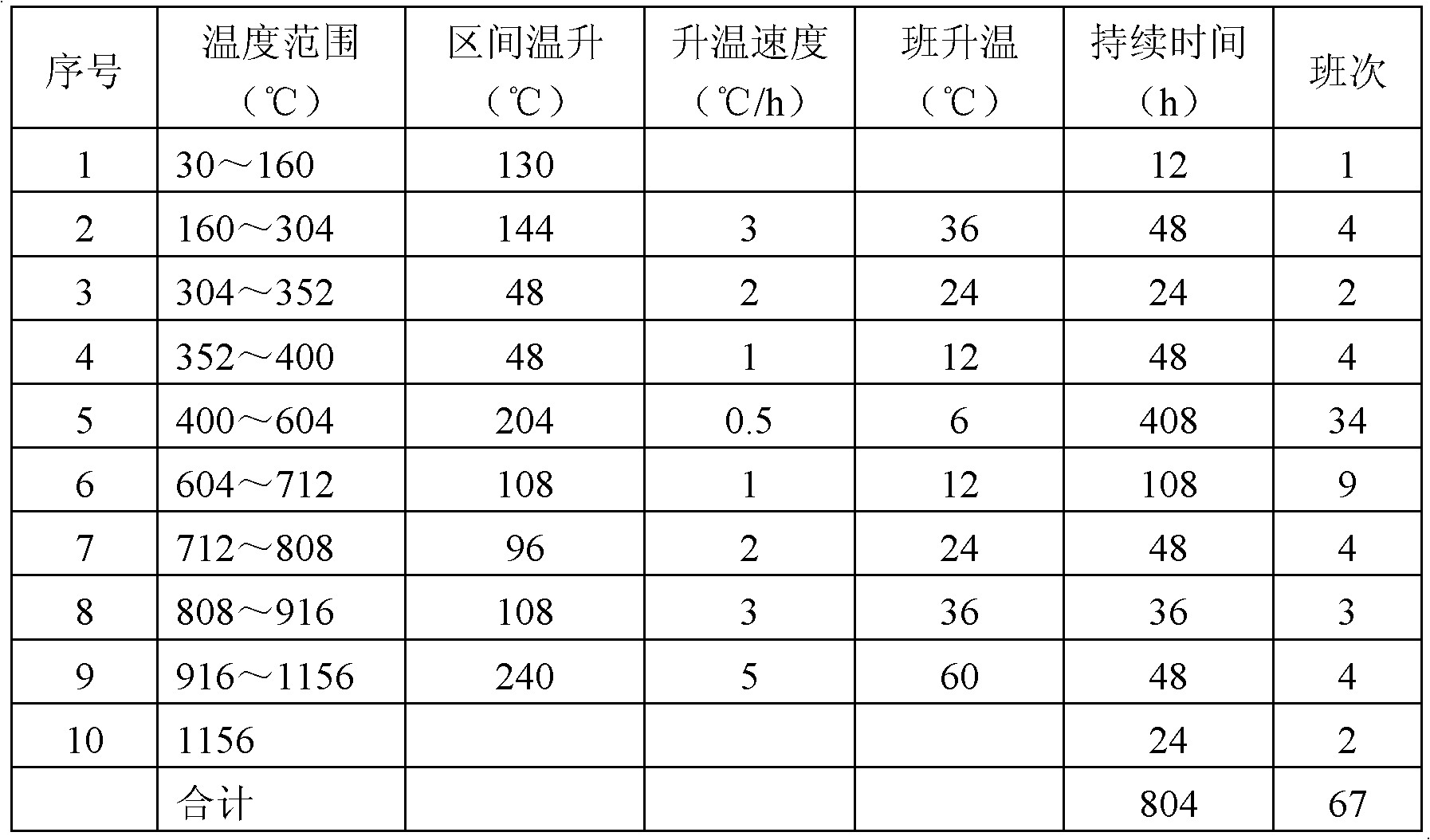

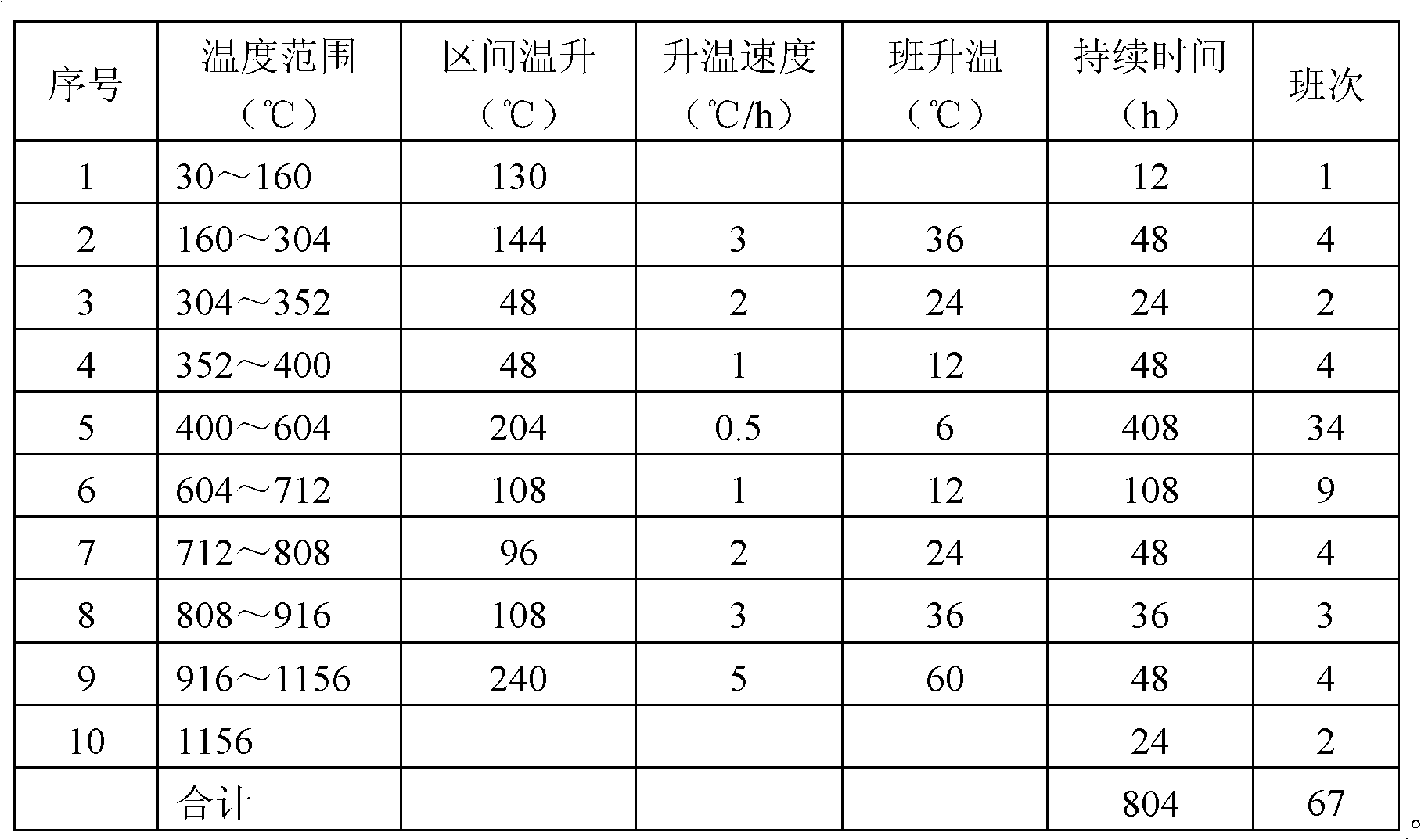

[0028] 3) Put the sagger in the roasting furnace, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com