Panel punching device

A punching device and flat plate technology, which is applied in metal processing and other directions, can solve the problems that the flat plate cannot be fixed on the workbench, the problem of flat plate positioning, etc., and achieves the effect of good practical value, simple structure and improved punching accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

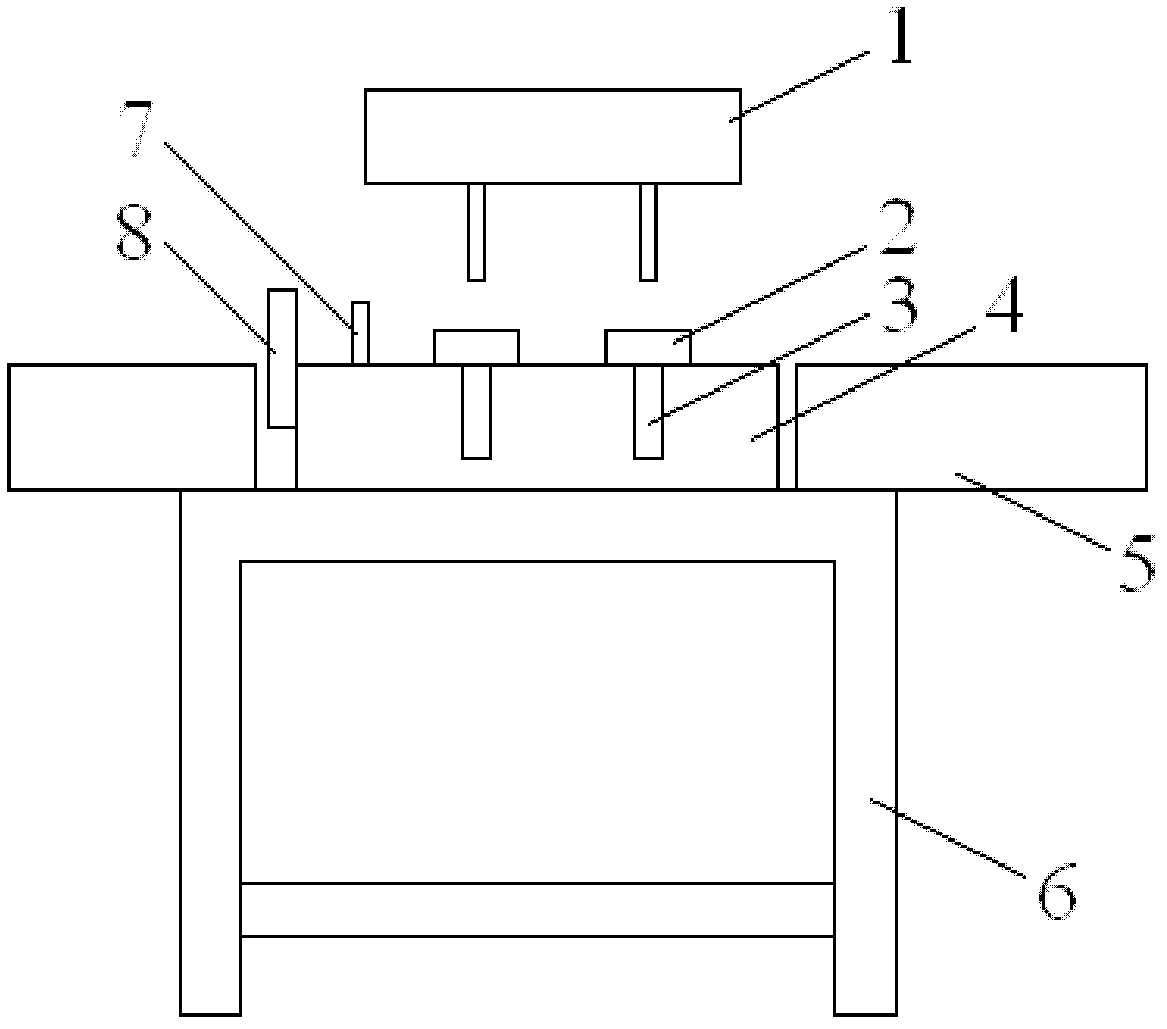

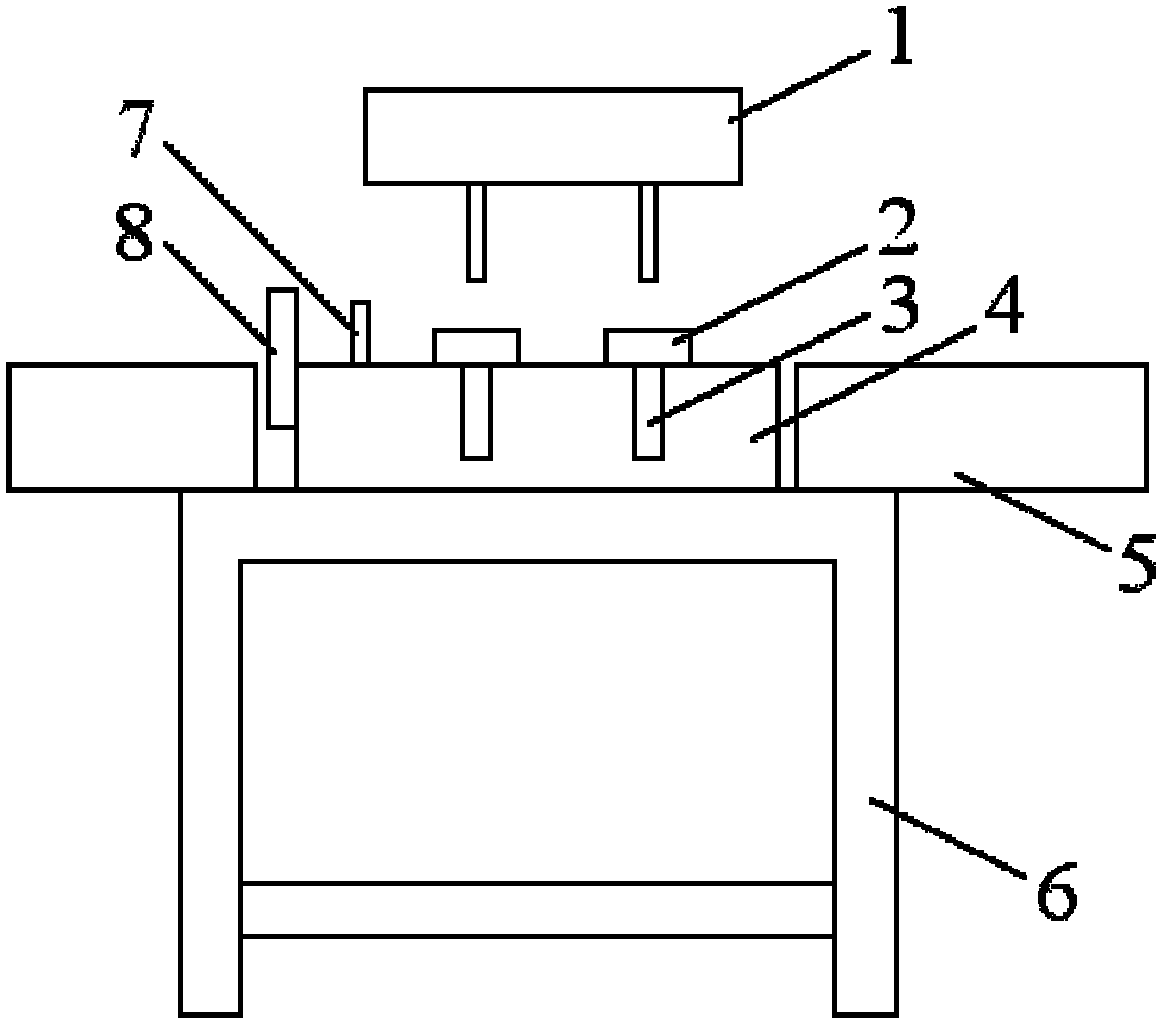

[0012] see figure 1 , a flat plate punching device, including a base 6, the base 6 is provided with a workbench 4, a positioning column 7 is fixedly installed on one side of the upper surface of the workbench 4, and the workbench 4 located on the inner side of the positioning column 7 is respectively provided with There are two concave cavities 3, and the spacing between the positioning column 7 and the two concave cavities 3 and the spacing between adjacent concave cavities are respectively the same; A positioning block 2, the outside of the positioning column 2 is provided with a baffle 8; the top of the workbench is provided with a punch 1, and the punch 1 is facing two concave cavities 3 on the workbench 4 respectively.

[0013] A flat plate is placed on the workbench 4, and the edges of the adjacent two sides of the plate are respectively against the inner side of the baffle plate 8 and the two positioning blocks 2; The stamping of the flat plate provides reliable suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com