High-dryness filter and method

A high-dryness, filter technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of high labor intensity, difficulty in separating the filter cake from the filter cloth, explosive frame, etc., to save labor costs, Low energy consumption and the effect of increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

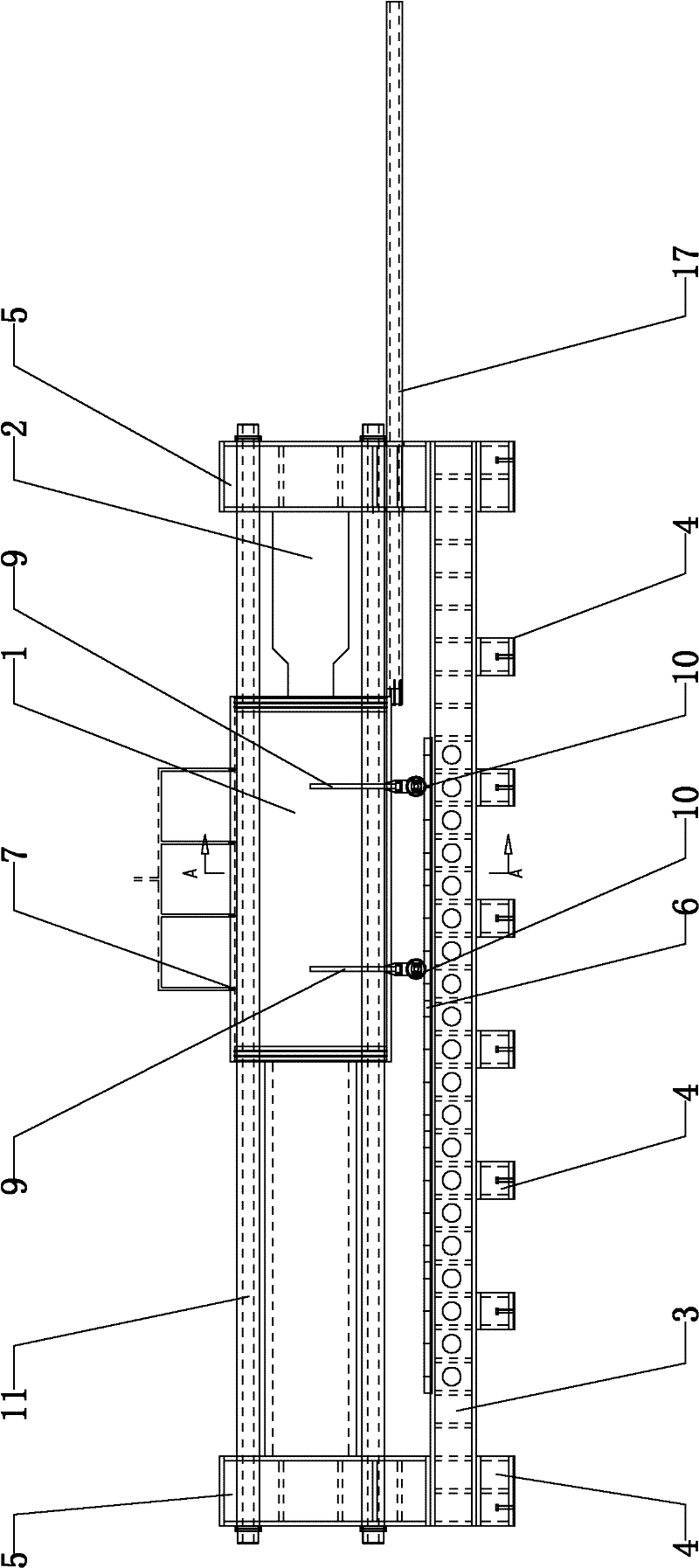

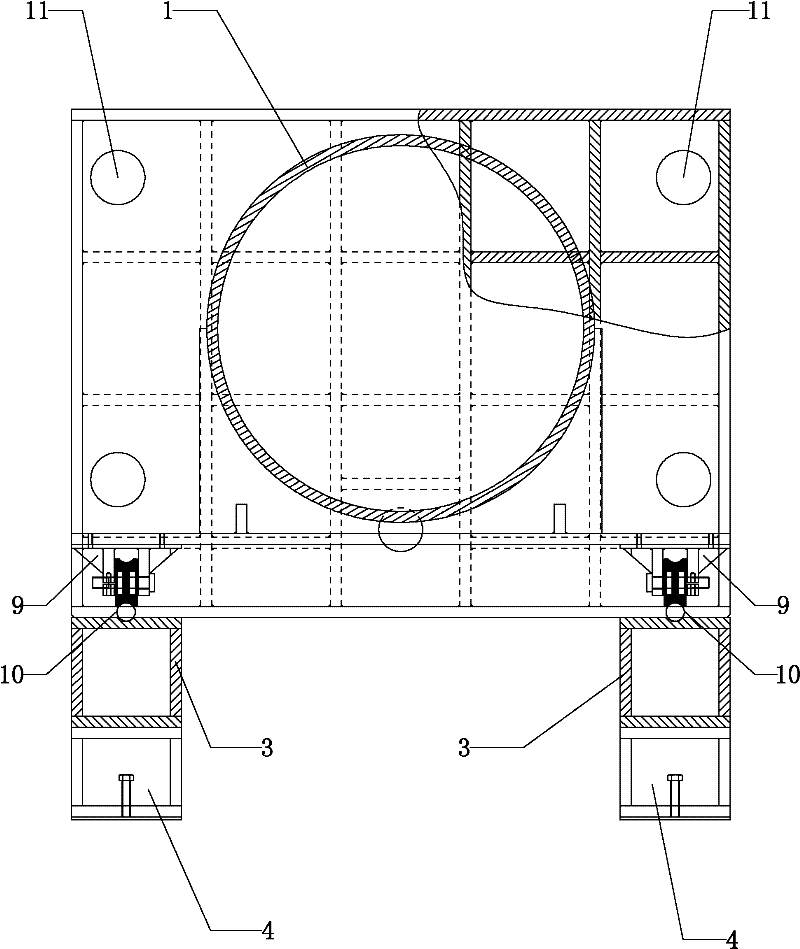

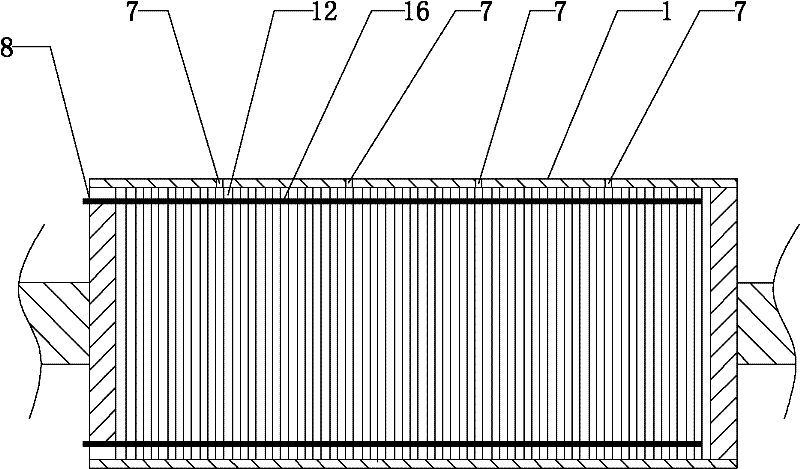

[0026] Such as Figure 1-6 As shown, one form of the present invention described in the embodiment of the present invention is a high-dryness filter, including a cylinder body 1, a hydraulic cylinder 2 and two beam joints 3, and the two beam joints 3 The bottom is welded with a number of foot box joints 4 respectively, and the tops of the two beam joints 3 are provided with side box joints 5 near both ends, and the bottoms of the side box joints 5 are welded to the two cross beam joints 3 respectively. On the top, two crossbeam joints 3 are provided with guide rails 6 close to the middle, and a cylinder body 1 is arranged above the guide rails 6. Several water inlets 7 are arranged on the outer surface of the cylinder body 1, and the water inlets 7 are connected to the water inlet pipes. The left end face of the body 1 is provided with a water outlet 8, the bottom of the cylinder body 1 is provided with a supporting rod 17 near the right end, and the front and rear sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com