Container for mixing and degassing equipment, and mixing and degassing equipment

A technology of stirring and defoaming, containers, applied in mixers with rotating containers, liquid degassing, transportation and packaging, etc., can solve the problem of uneven mixing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

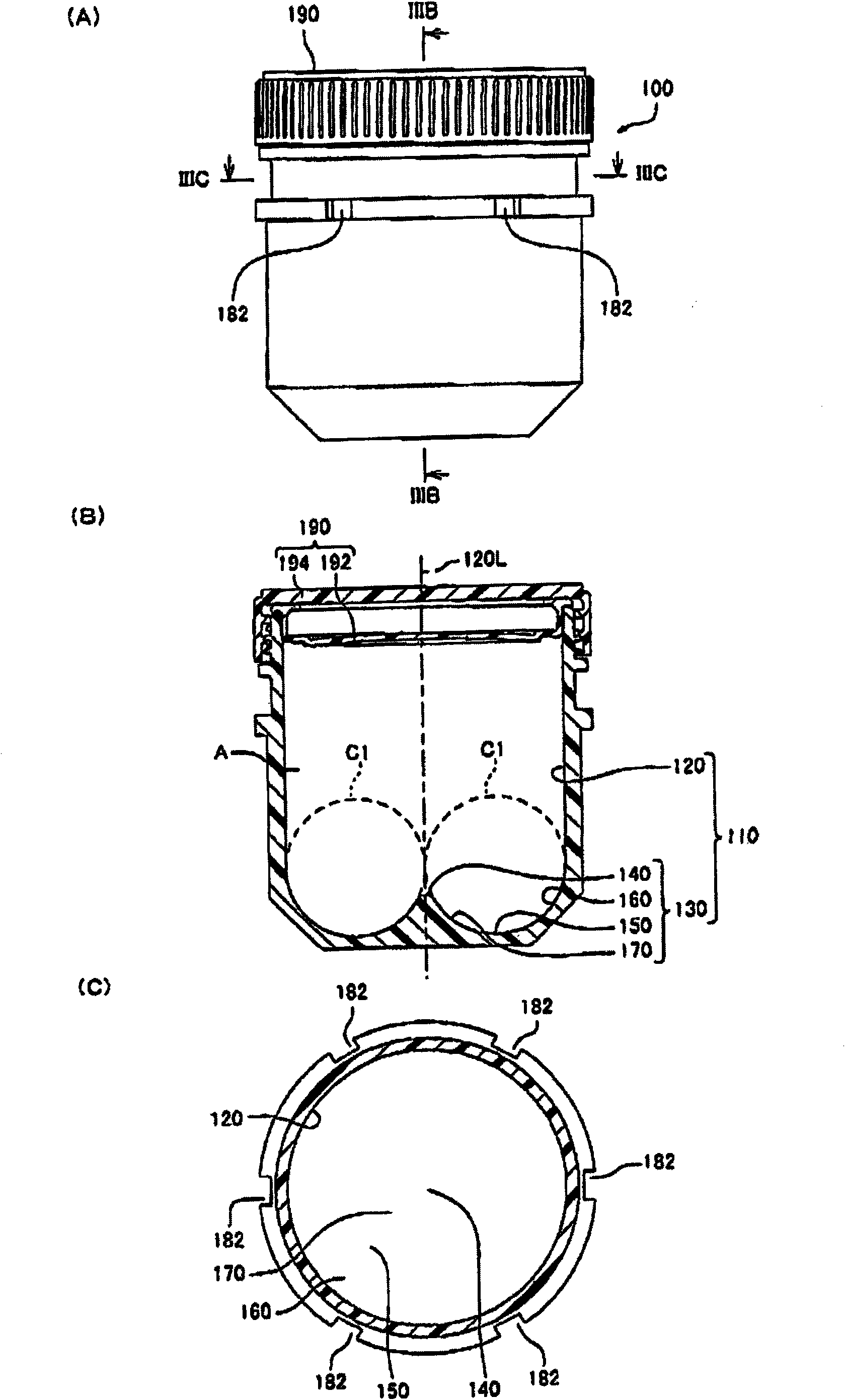

[0029] Hereinafter, embodiments used in the present invention will be described with reference to the drawings. However, the present invention is not limited to the following embodiments. That is, the present invention is not necessarily limited to all configurations described in the following embodiments. In addition, this invention includes the structure which combined the following content freely.

[0030] (1) Structure of Stirring Degassing Device 1

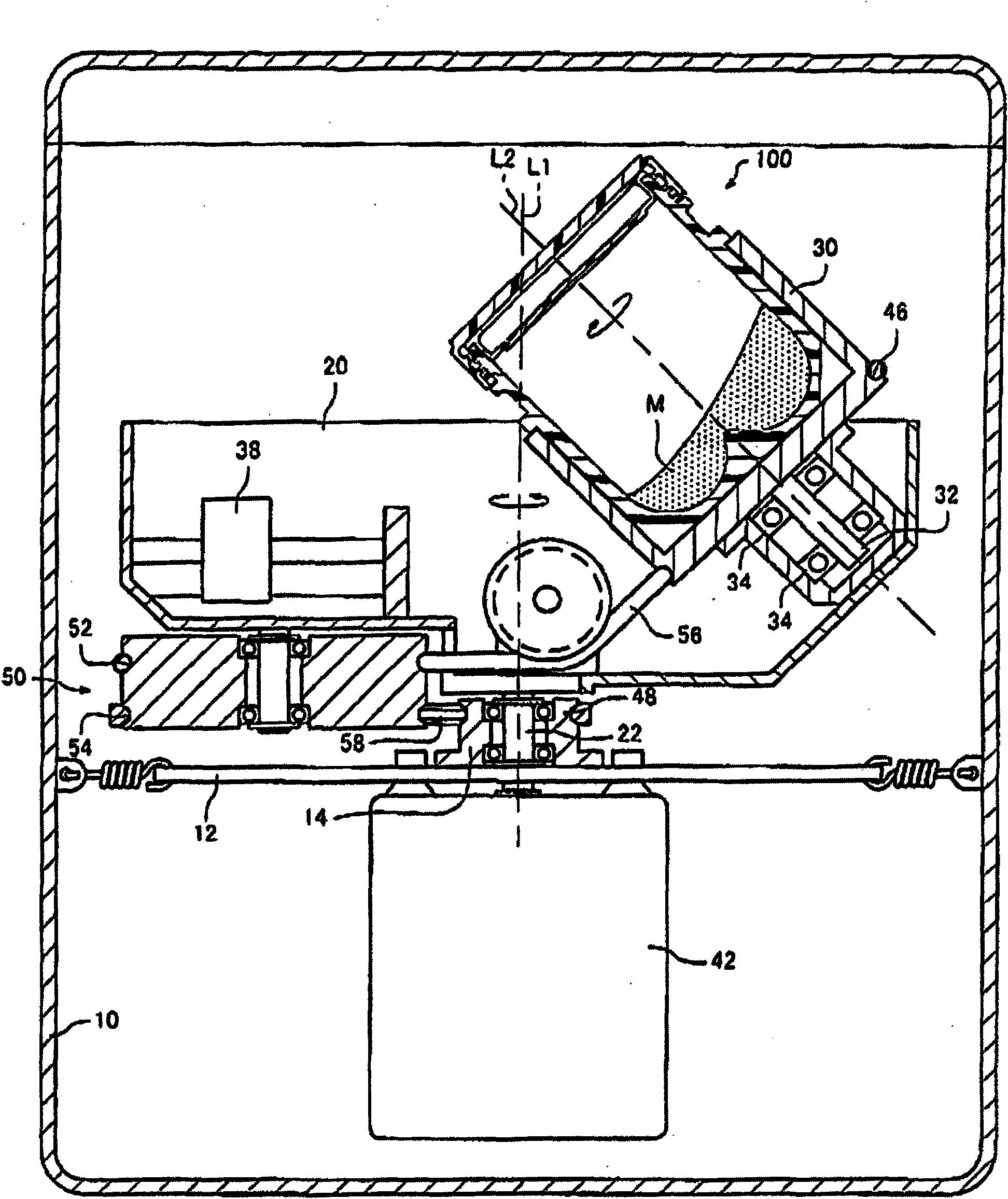

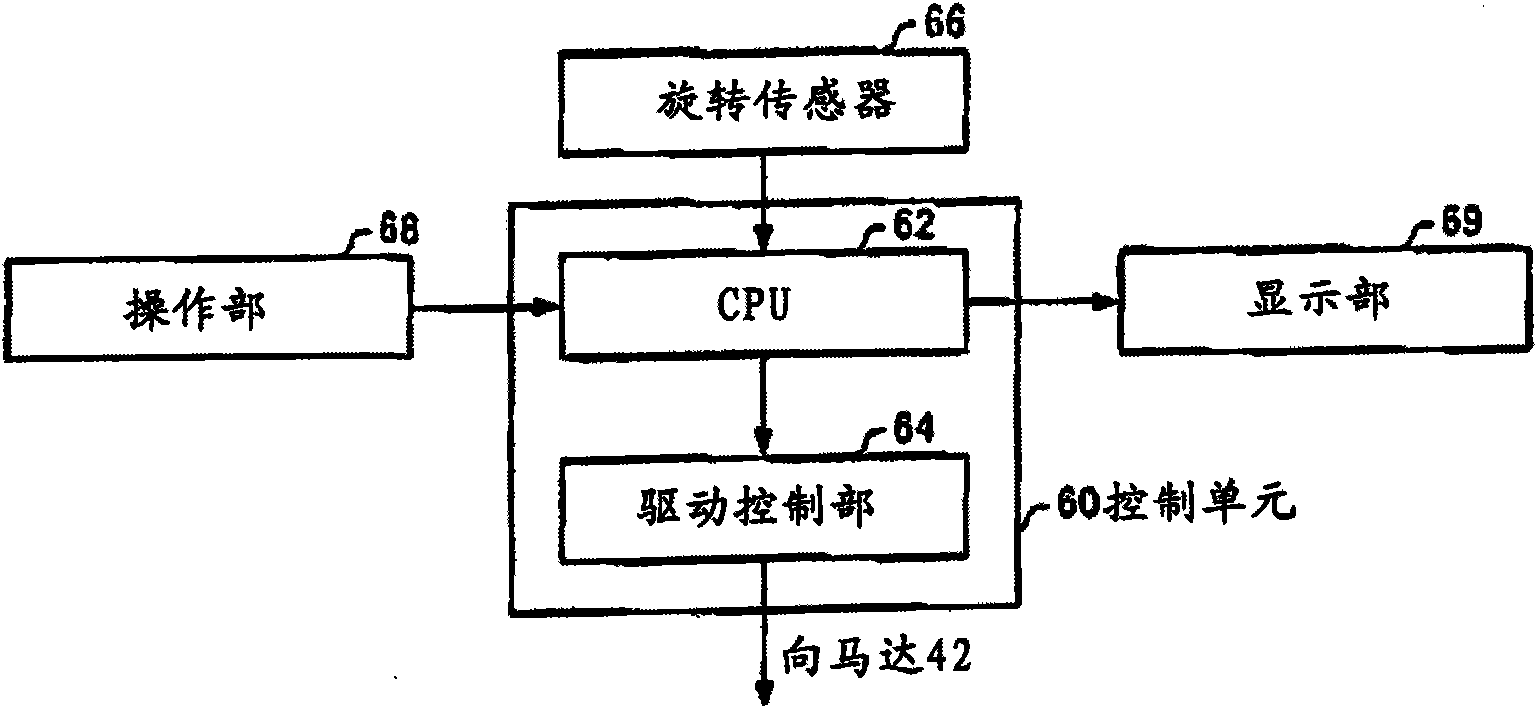

[0031] Below, refer to figure 1 and figure 2 The structure of the stirring degassing apparatus 1 of this embodiment is demonstrated.

[0032] (a) Housing 10

[0033] Such as figure 1 As shown, the stirring degassing device 1 has a housing 10 . A support substrate 12 for supporting various mechanisms described later is attached to the inside of the housing 10 via anti-vibration springs. In addition, a holding member 14 for holding a rotating shaft 22 of a rotating body 20 described later is attached to the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com