Method for preparing indigo naturalis

An indigo plant and plant technology, applied in the field of medicine, can solve the problems of affecting clinical efficacy, difficult to standardize the processing process, and uneven quality of indigo products, so as to expand the scope of clinical application, reduce the amount of lime, and achieve good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The preparation of embodiment 1 thick indigo of the present invention

[0014] Place the fresh leaves in tap water at 25°C with a pH of about 3.5, wherein the volume of water: mass of fresh leaves (ml: g) is 13, soak in the dark for 24 hours, filter to remove leaf residue, add ammonia water to adjust the pH of the filtrate to 9, and then After ventilating the air for 30 minutes, add 10% fresh milk of lime (take 10% CaO of fresh leaves, add 10 times the amount of boiling water, stir continuously to form a suspension), stir well and let stand for 24 hours, filter Take the precipitate and dry it to get crude indigo.

Embodiment 2

[0015] The preparation of embodiment 2 thick indigo of the present invention

[0016] Place the fresh leaves in tap water at 60°C with a pH of about 7, wherein the volume of water: mass of fresh leaves (ml: g) is 15, soak for 48 hours, filter to remove leaf residue, ventilate the filtrate for 30 minutes, add ammonia water to adjust the pH of the filtrate to 10.5, after ventilating the air for 180 minutes, add 10% fresh milk of lime (take 10% CaO of fresh leaf mass, add 10 times the amount of boiling water, stir continuously to form a suspension), stir evenly and let stand After 24 hours, the precipitate was collected by filtration and dried to obtain crude indigo.

Embodiment 3

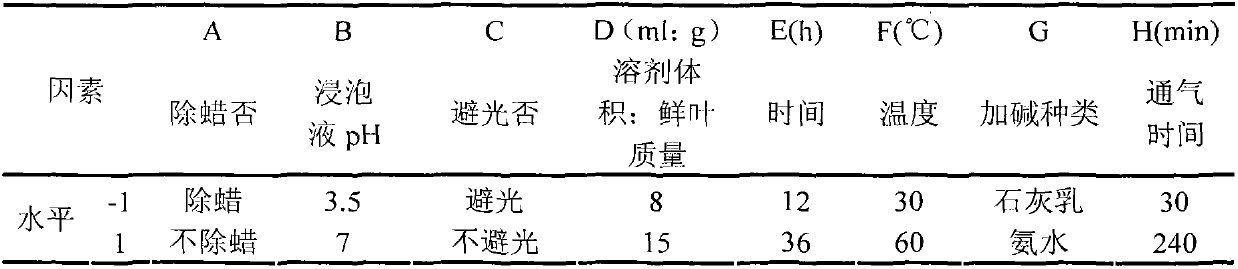

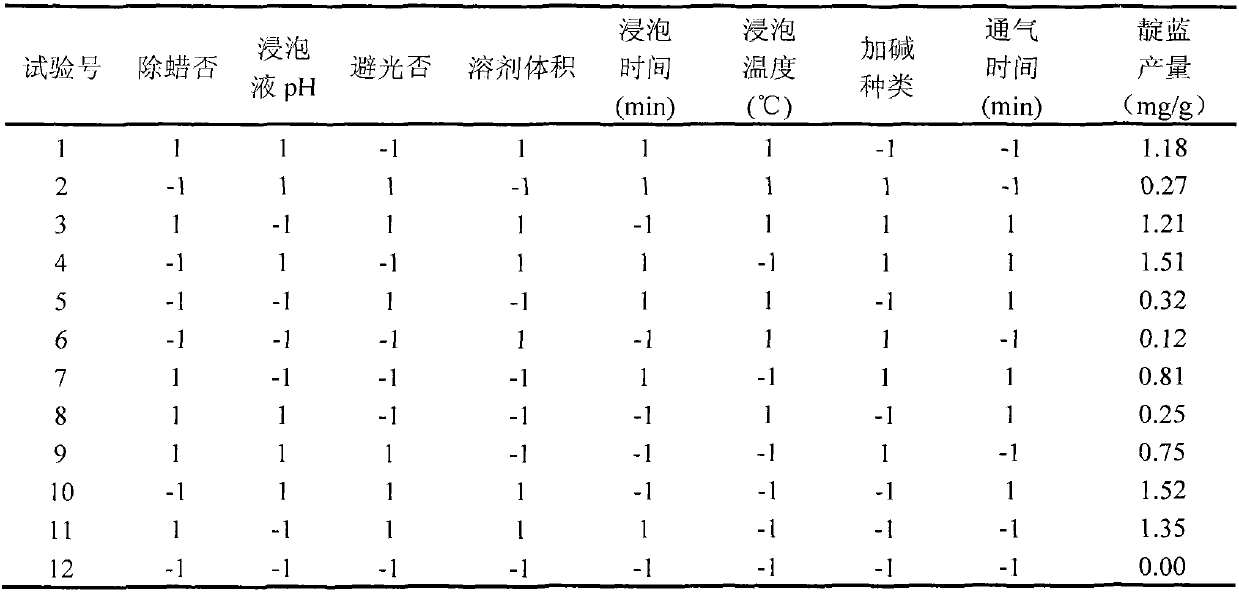

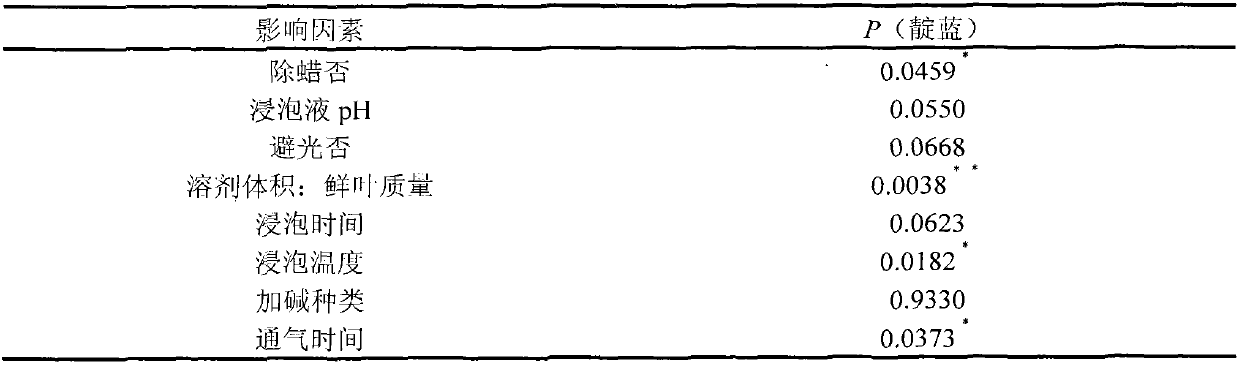

[0017] The process parameter selection of indigo directional generation in the rough indigo processing process of embodiment 3

[0018] 1. Instruments and reagents

[0019] Shimadzu LC-10ATvp high-performance liquid chromatography (Zhejiang Zhida N2000 chromatographic workstation); BP211D electronic analytical balance (Max=210g, d=0.01mg, Sartorius, Germany); KQ-400DB numerical control ultrasonic cleaner (Kunshan Ultrasonic Cleaner) Instrument Co., Ltd.); SZ-93 automatic double pure water distiller (Shanghai Yarong Biochemical Instrument Factory); LZB-FB rotameter (Suzhou Chemical Instrument Co., Ltd.); ACO series electromagnetic air compressor (Zhejiang Sensen Industry Co., Ltd.); SHB-ⅢS circulating water multi-purpose vacuum pump (Zhengzhou Great Wall Technology Industry and Trade Co., Ltd.)

[0020] Malan stems and leaves (provided by Sichuan Jiangyou Hengyuan Pharmaceutical); indigo (National Institute for the Control of Pharmaceutical and Biological Products, batch numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com