Fluid-filled vibration damping device

A vibration isolation and fluid technology, applied to shock absorbers, shock absorber-spring combinations, springs, etc., can solve problems such as difficult to quickly change the size of the gap, fluid inflow or outflow resistance, etc., to achieve easy management and improve Effect of improving reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

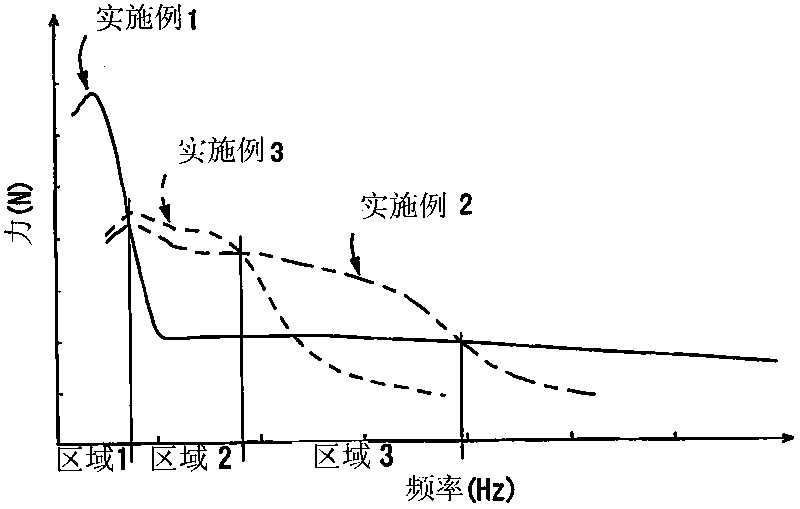

[0073] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0074] first, figure 1 An automobile engine mount 10 as a first embodiment of the fluid-filled vibration isolator of the present invention is shown. This engine mount 10 has a structure in which a first mounting member 12 and a second mounting member 14 are arranged to face apart from each other, and the main body rubber is interposed between the first mounting member 12 and the second mounting member 14 . The elastic body 16 is elastically connected to form a bracket body 18 embedded in the bracket 20 . In addition, in the engine mount 10, the first mounting member 12 is mounted on a power unit (not shown), and the second mounting member 14 is mounted on a vehicle body (not shown), so that the power unit is vibration-isolated and supported on the vehicle body. . In addition, in the mounting state as described above, in this engine mount 10, the load sharing of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com