Alcohol receiving station

A connected, highly volatile technology, applied in alcohol receiving equipment and in the field of alcohol receiving, can solve problems such as prolonging the receiving process and disturbing variables, and achieve good degassing, constant mixing accuracy, and good mixing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

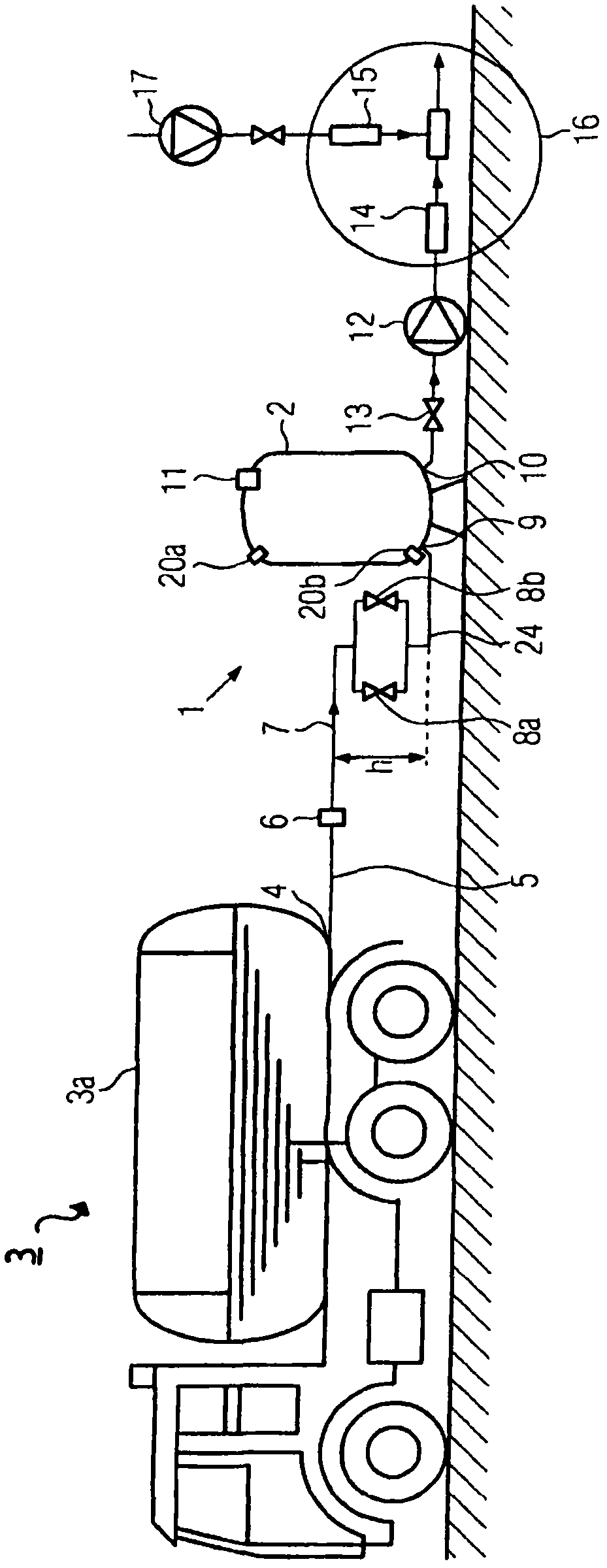

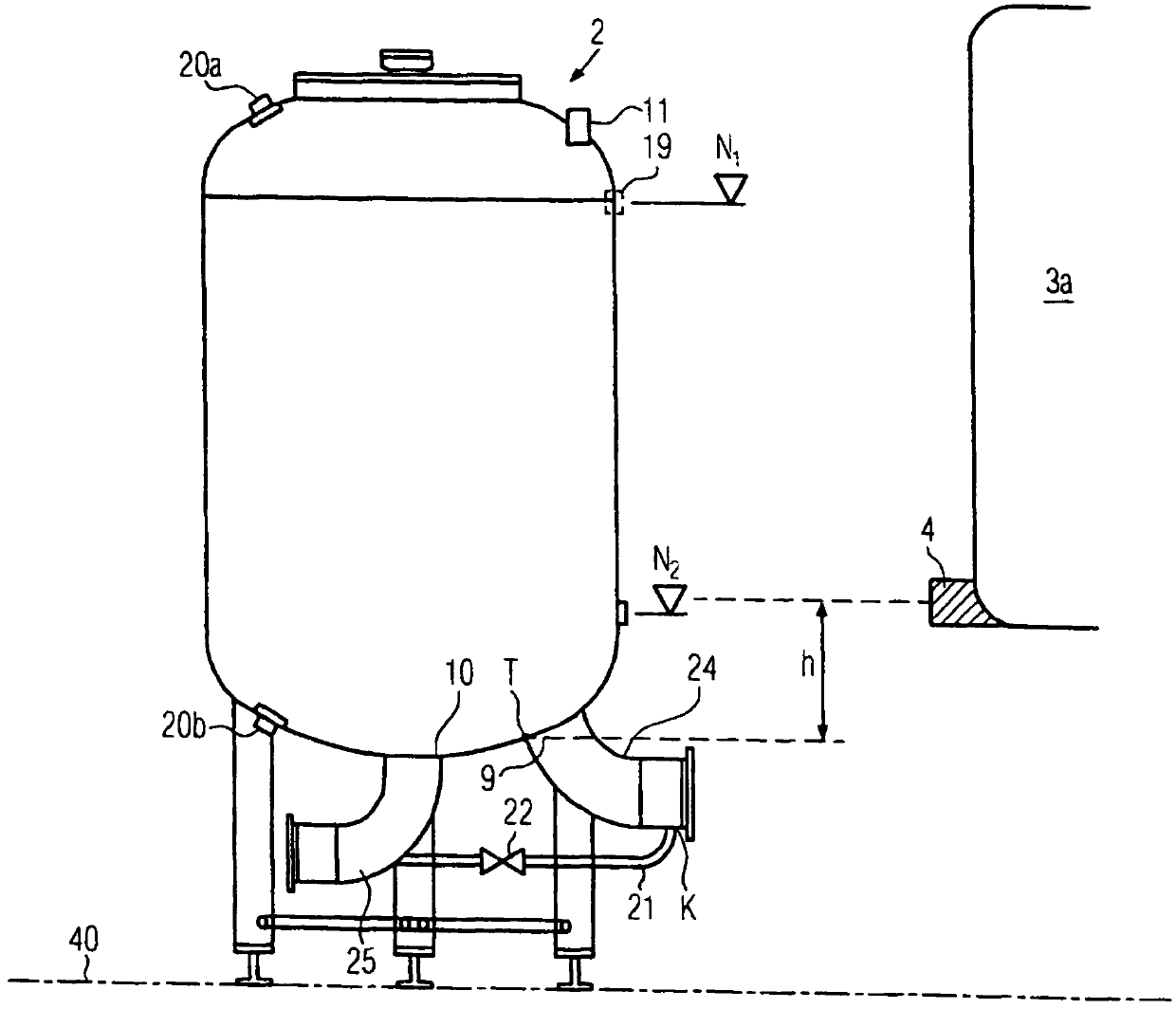

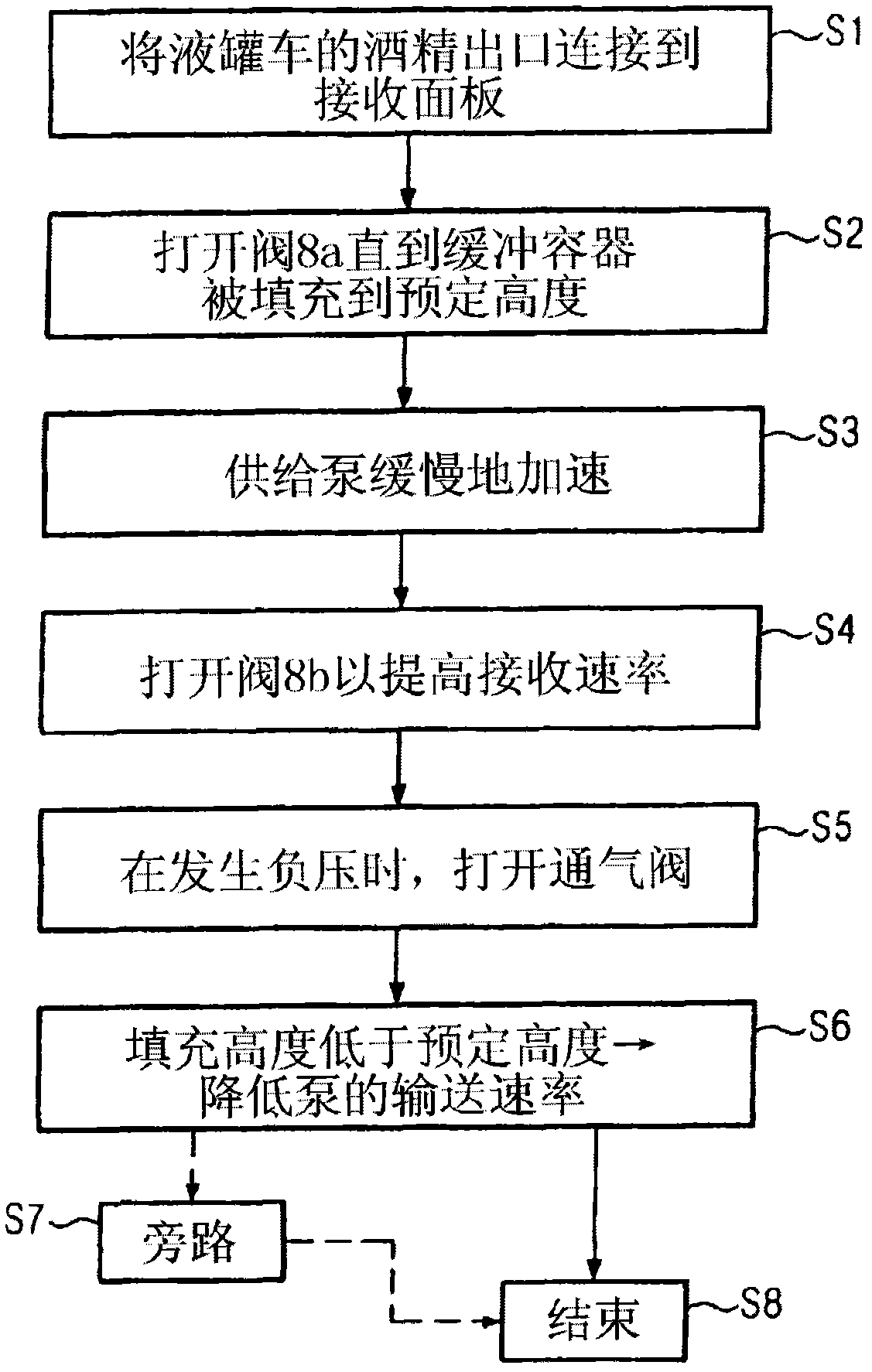

[0028] figure 1 A schematic diagram of a device for receiving alcohol from a tank truck 3 is shown. The tank truck 3 has a liquid tank 3a, the liquid tank 3a has for example a 20 to 40 m 3of storage capacity. In the lower region of the tank 3a there is an alcohol outlet 4, which is connected via a hose 5 and a connection 6 to, for example, a panel 7 of a device for receiving alcohol, which is only schematically depicted as a line in the figure straight line. The panel 7 includes corresponding ducts by means of which alcohol can be introduced into the degassing container 2 . The alcohol supply line is divided into two lines with two valves 8a, 8b arranged parallel to each other. The two lines then flow together again into the common line 8 . The valves 8a, 8b are not regulating valves in which the flow rate can be adjusted, but seat valves with only a low pressure loss. The seat valves 8a, 8b can be opened and closed independently of each other by means of a controller no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com