Automatic piece wrapping machine for storage battery pole pieces

An automatic wrapping machine and storage battery technology, which is applied in the direction of electrode manufacturing, etc., can solve the problems affecting the quality of wrapping, poor dimensional accuracy, low efficiency, etc., and achieve the effect of improving reliability and service life and ensuring the quality of wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

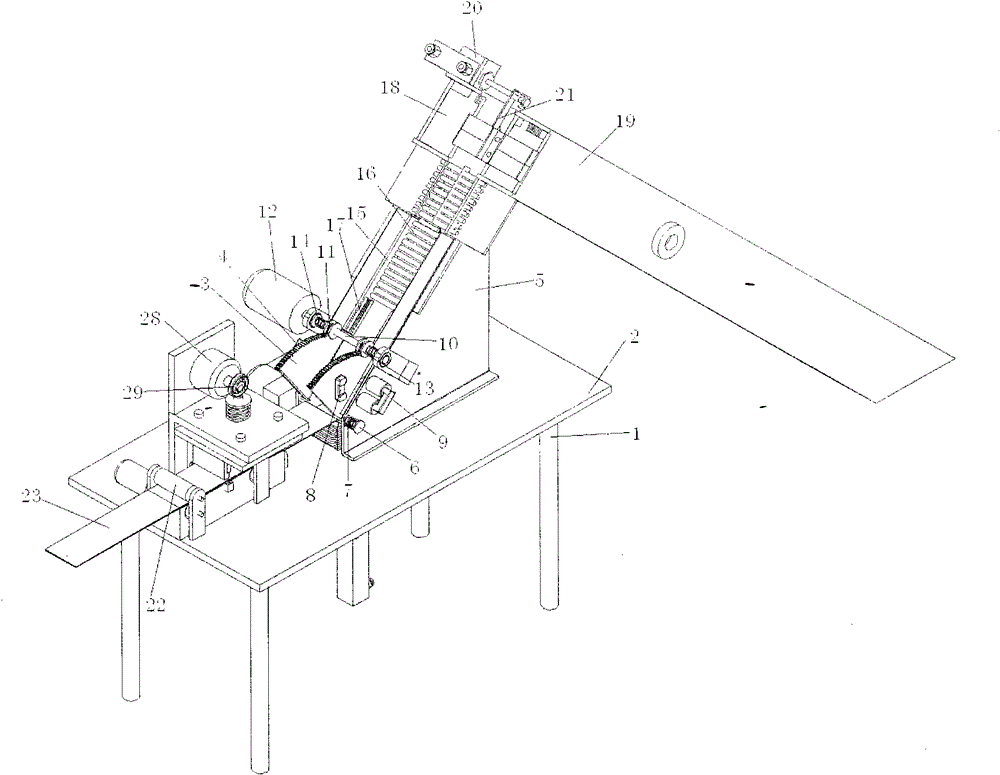

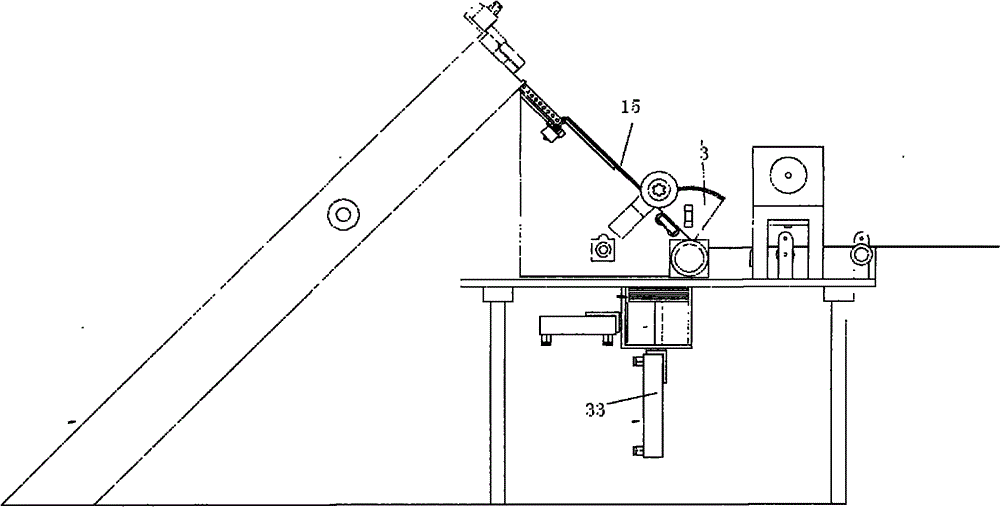

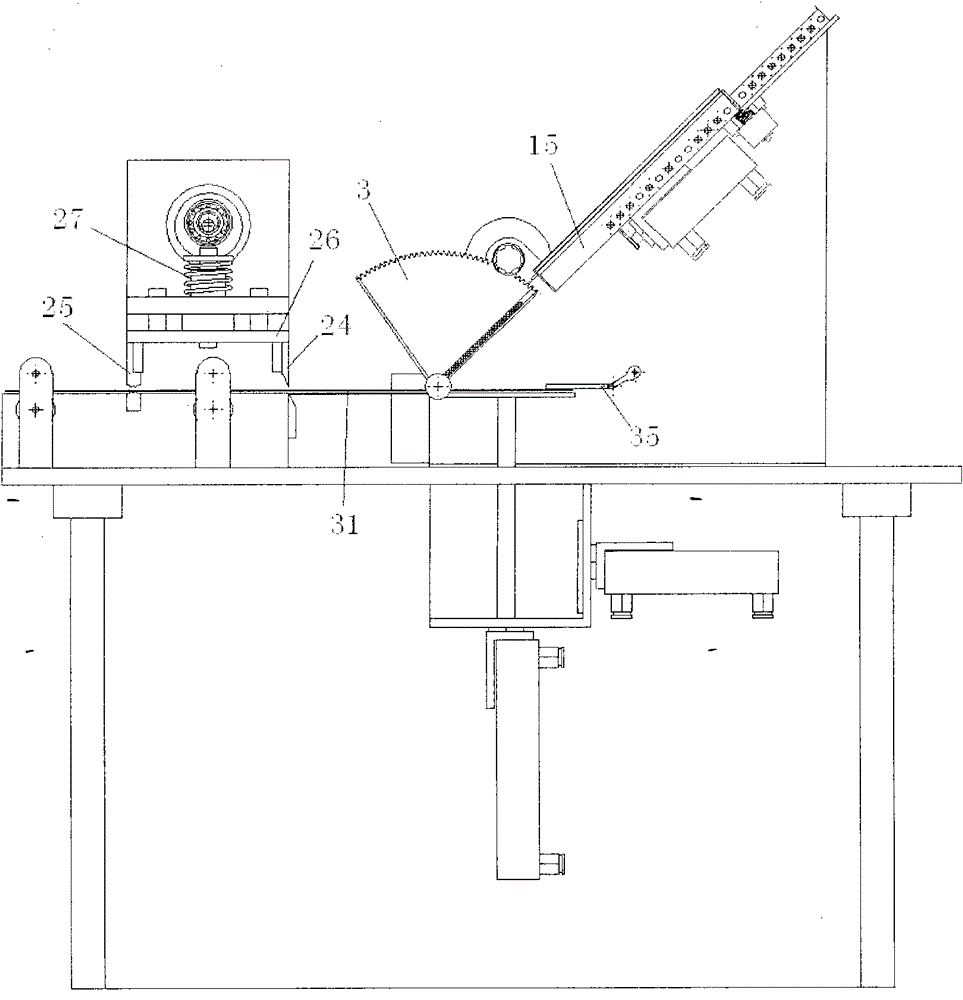

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , an automatic battery pole sheet wrapping machine, including a frame 1 and a working platform 2 arranged on the frame 1, and also includes two vertical fan-shaped plates 3, the arc surface of the fan-shaped plate 3 is on the top, The arc surface of the fan-shaped plate is provided with tooth lines 4 .

[0040] The fan-shaped plate 3 can translate to the outside, and the frame 1 is provided with a lateral drive mechanism for driving the fan-shaped plate 3 to translate to the outside, and the fan-shaped plate 3 is also provided to make it move outward Reset mechanism for reset after translation. In this embodiment, the working platform 2 is provided with two vertical facade side panels 5, and the two facade side panels 5 are pierced with a rotary shaft 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com