Energy-saving feedback oriented elevator group control scheduling method

A dispatching method and group control dispatching technology, applied in the direction of elevator energy efficiency, self-adaptive control, general control system, etc., can solve the problem of lack of performance, the energy-saving feedback characteristics of a single elevator cannot be fully utilized, and energy-saving group control dispatching cannot be realized. and other problems to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

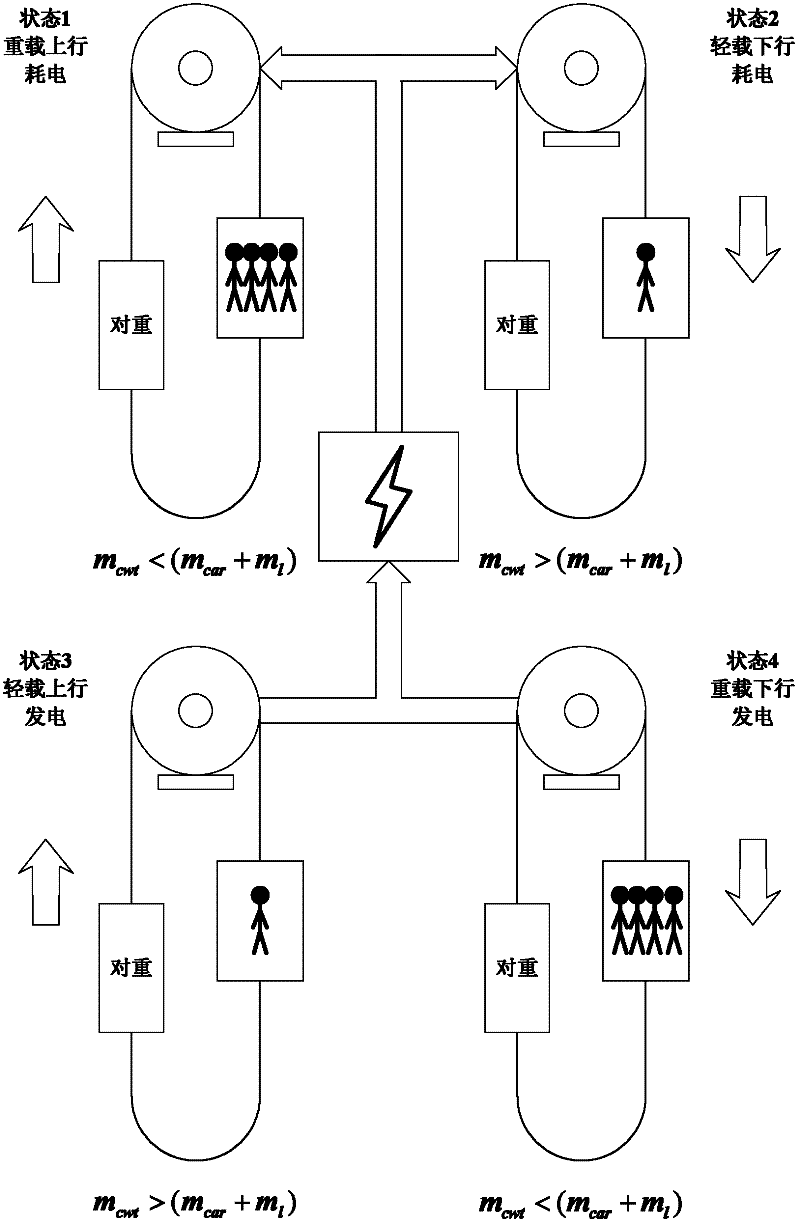

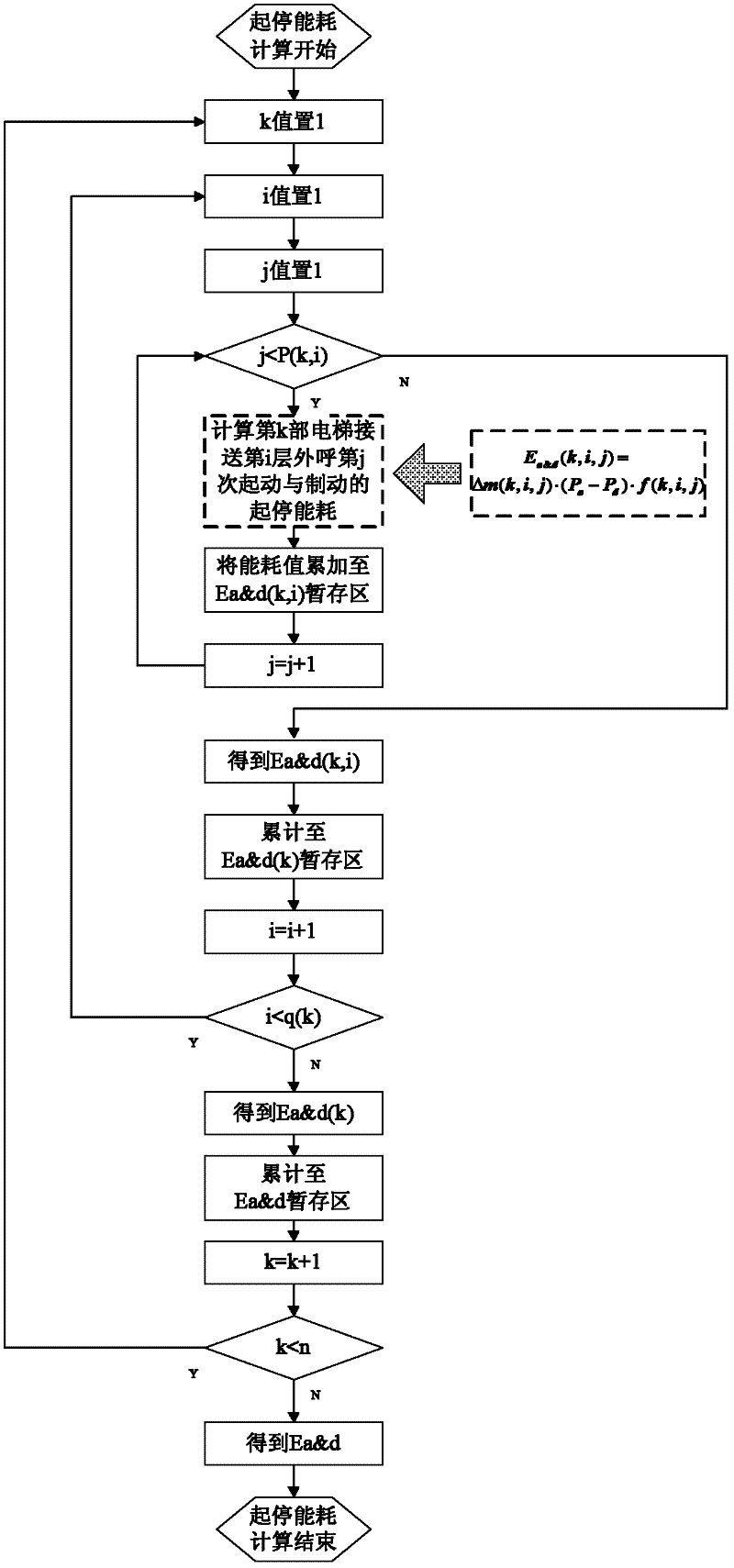

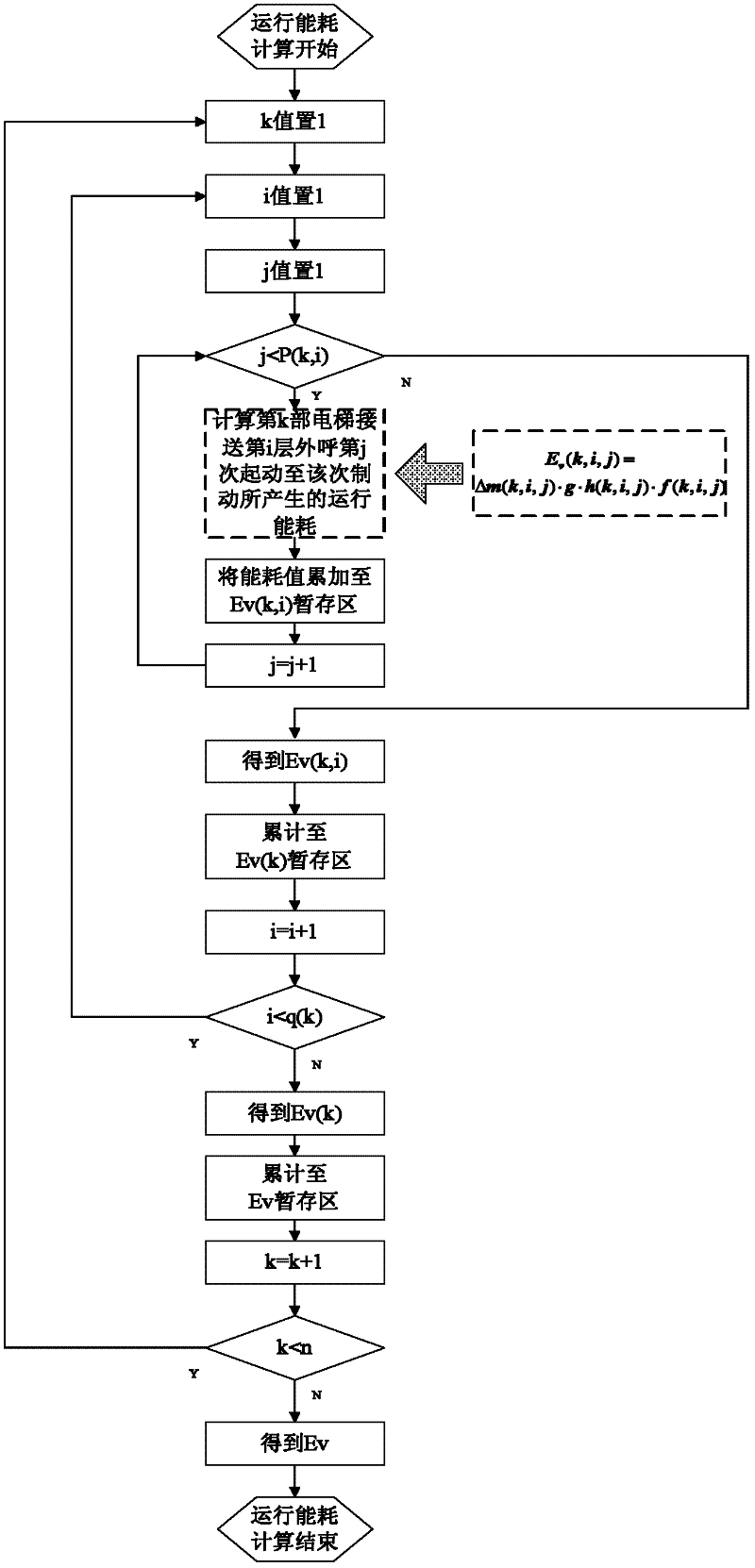

[0050]The present invention proposes an elevator group control scheduling method with energy-saving feedback by means of the energy-saving technology of a single elevator with feedback frequency conversion, so as to maximize the energy-saving feedback advantages of each single elevator in the group control system, thereby achieving a good energy-saving effect for a single elevator It can be applied to the energy saving of elevator group control. In addition to effectively reducing the energy consumption of the entire system, this method also has the function of feedback power generation, and the generated energy can be used by the grid or buildings.

[0051] (First, the purpose

[0052] The purpose of the present invention is to propose an elevator group control dispatching method oriented to energy-saving feedback.

[0053] With the continuous development of frequency conversion feedback single-elevator technology, elevators with energy-saving feedback functions have become m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com