On-line virtual testing system of steel cord conveyor belt and testing method thereof

A technology of virtual testing and conveyor belt, applied in the direction of using radiation for material analysis, etc., can solve the problems of conveyor belt jitter and deviation, insufficient data storage and processing function, low accuracy of fast image acquisition, etc. Achieve short-time exposure, which is beneficial to online testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

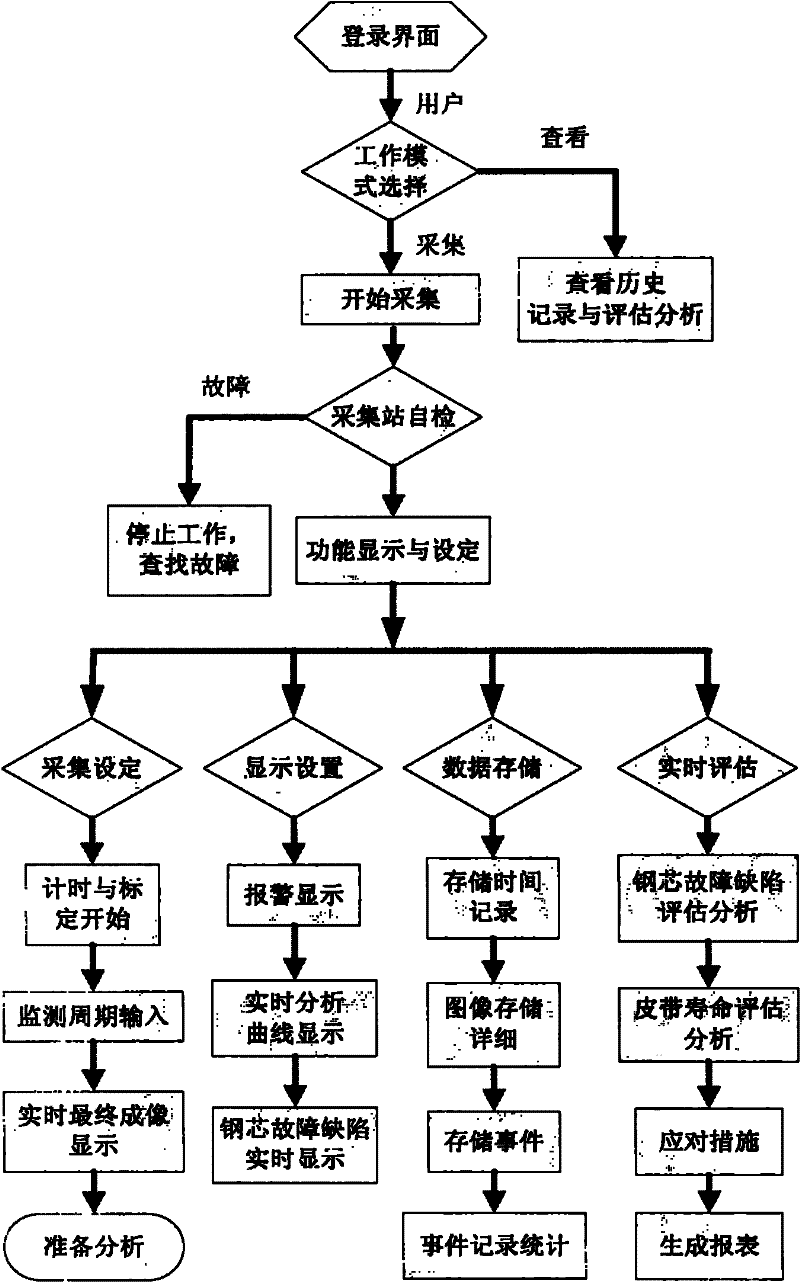

[0058] Below in conjunction with accompanying drawing, the implementation of the present invention is described in detail as follows:

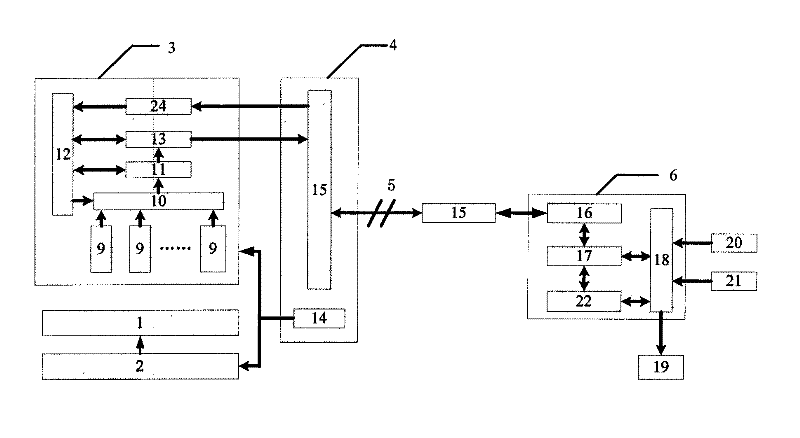

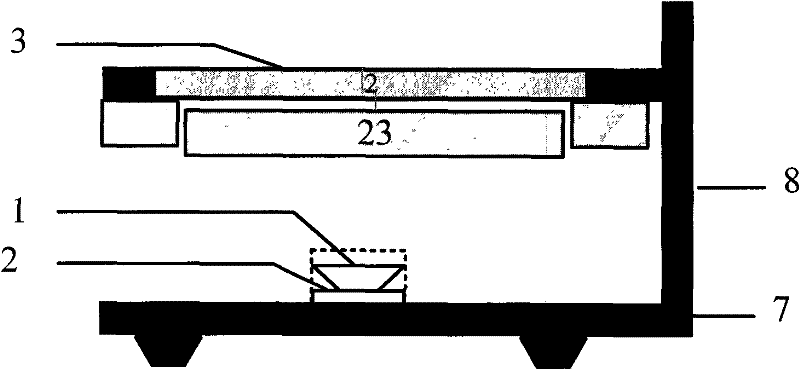

[0059] Such as figure 1 As shown, the online virtual test system for steel cord conveyor belt is mainly composed of X-ray source 1, high-frequency and high-voltage generator 2, scanning detection device 3, explosion-proof junction box 4, optical cable 5, upper computer 6, base plate 7 and column 8 . X-ray source 1, high-frequency and high-voltage generator 2 and scanning detection device 3 form the test hardware circuit part to realize the image data acquisition function, explosion-proof junction box 4, optical cable 5 and host computer 6 to realize remote image transmission, testing and analysis, base plate 7 A steel plate with a length and width of 400mm×200mm and a thickness of 4-6mm is used. The left edge of the steel plate is welded together with the column 8. The column 8 is welded with a 2mm steel plate to form a 30mm×25mm×900mm rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com