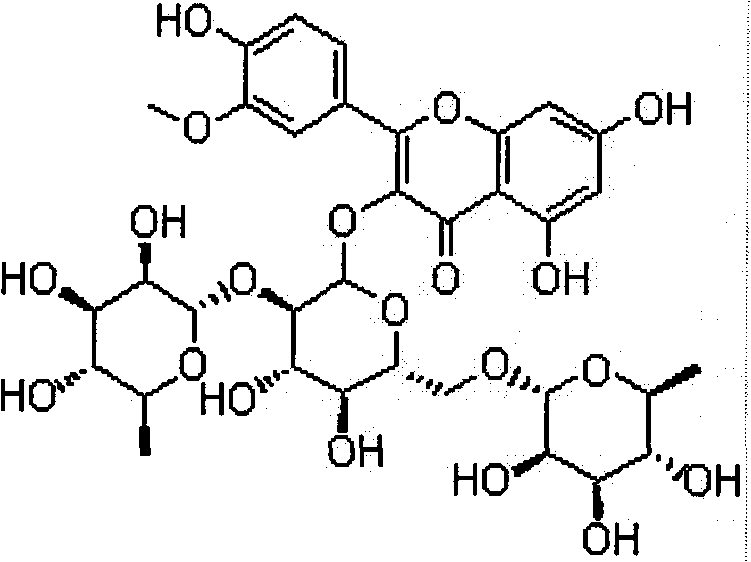

Separation and preparation process of high-purity typhaneoside

A technology for the preparation of typhaloside and its preparation technology, which is applied in the field of separation and preparation of high-purity typhaloside, which can solve the problems of long production cycle and high cost, achieve the effects of large preparation volume, good product purity, and overcoming cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 2 kg of Puhuang into the extraction kettle of the supercritical extraction device, and use supercritical CO 2 As a solvent, the supercritical extraction of Puhuang was carried out, the extraction pressure was 28MPa, the temperature was 45°C, the extraction time was 3 hours, CO 2 The flow rate is 25L / h. After the environment in the extraction tank is stable, add 65% acetone carrier (20% of the amount of medicinal material) to the carrier storage tank, adjust the temperature of the analyte to 55°C, and the pressure to be 8MPa. The extract released from the outlet. The extract was extracted with n-butanol, and concentrated under reduced pressure to obtain 244 g of extract. Take 50g of extract and add silica gel (extract: silica gel = 1:3), stir evenly, dry at low temperature, then use new silica gel to pack, mix sample silica gel to put on column, chloroform-ethanol mixed solution is 9:1, 7: 1, 4:1, 2:1, 1:1, 1:2 for gradient elution, the amount of each gradient elue...

Embodiment 2

[0021] 5kg of Puhuang is packed in the extraction still of supercritical extraction device, with supercritical CO 2 As a solvent, carry out the supercritical extraction of Puhuang, the extraction pressure is 33MPa, the temperature is 32°C, the extraction time is 1.5 hours, CO 2 The flow rate is 28L / h. After the environment in the extraction tank is stable, add 70% acetone carrier (22% of the amount of medicinal material) to the carrier storage tank, adjust the temperature of the analyte to 40°C, and the pressure to be 4MPa. The extract released from the outlet. The extract was extracted with n-butanol and concentrated under reduced pressure to obtain 595 g of extract. Take 50g of extract and add silica gel (extract: silica gel = 1:4), stir evenly, dry at low temperature, then pack with new silica gel, mix the sample silica gel onto the column, and mix the chloroform-ethanol solution in a volume ratio of 9:1, 7: 1, 4:1, 2:1, 1:1, 1:2 for gradient elution, the amount of each g...

Embodiment 3

[0024] Put 8 kg of Puhuang into the extraction kettle of the supercritical extraction device, and use supercritical CO 2 As a solvent, the supercritical extraction of Puhuang was carried out, the extraction pressure was 38 MPa, the temperature was 43 ° C, the extraction time was 2 hours, CO 2 The flow rate is 30L / h. After the environment in the extraction tank is stable, add 90% acetone carrier (23% of the amount of medicinal material) to the carrier storage tank, adjust the temperature of the analyte to 47°C, and the pressure to be 10MPa. The extract released from the outlet. The extract was extracted with n-butanol, and concentrated under reduced pressure to obtain 1 kg of extract. Take 50g of extract and add silica gel (extract: silica gel = 1:2), stir evenly, dry at low temperature, then use new silica gel to pack, mix sample silica gel to put on column, chloroform-ethanol mixed solution is 9:1, 7: 1, 4:1, 2:1, 1:1, 1:2 gradient elution, the amount of each gradient eluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com