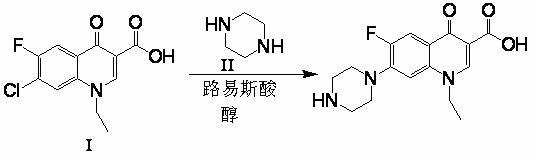

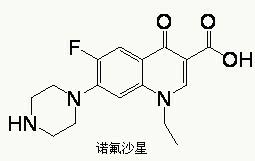

Chemical preparation method of norfloxacin

A norfloxacin and chemical technology, applied in the field of chemical preparation of norfloxacin, can solve the problems of poor selectivity, no economic value, low product conversion rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

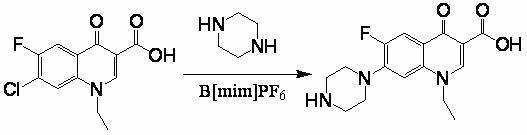

Method used

Image

Examples

Embodiment Construction

[0033] Example 1 , drop into 30g (0.111mol) 1-ethyl-6-fluoro-7-chloro-4-oxo-1,4-dihydro-quinoline-3-carboxylic acid, 60g piperazine (0.697mol) in four-necked flask mol), 75g of isoamyl alcohol, 1.5g of aluminum trichloride (0.0112mol), heated to 100 ° C for 12 hours, then added 4.5g of sodium hydroxide (0.113mol), recovered to dryness under reduced pressure, and added to the residue 150g water, 4.5g sodium hydroxide (0.113mol), 0.1g activated carbon, heat up to 90°C for 30 minutes, filter, adjust the pH of the obtained filtrate to neutral, cool to room temperature and suction filter, and dry the filter cake at 100°C 31.6 g of the product was obtained, and the liquid phase detection content was 99.5%, of which the content of the 6-position fluorine-substituted isomer was 0.1%. Yield 88.9%.

[0034] Example 2 , drop into 30g (0.111mol) 1-ethyl-6-fluoro-7-chloro-4-oxo-1,4-dihydro-quinoline-3-carboxylic acid, 27g piperazine (0.313 mol), 13g methanol, 30g aluminum trichloride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com