Production line of light weight foam concrete building board

A concrete construction and lightweight foam technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve problems such as heavy handling labor, high manufacturing costs, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

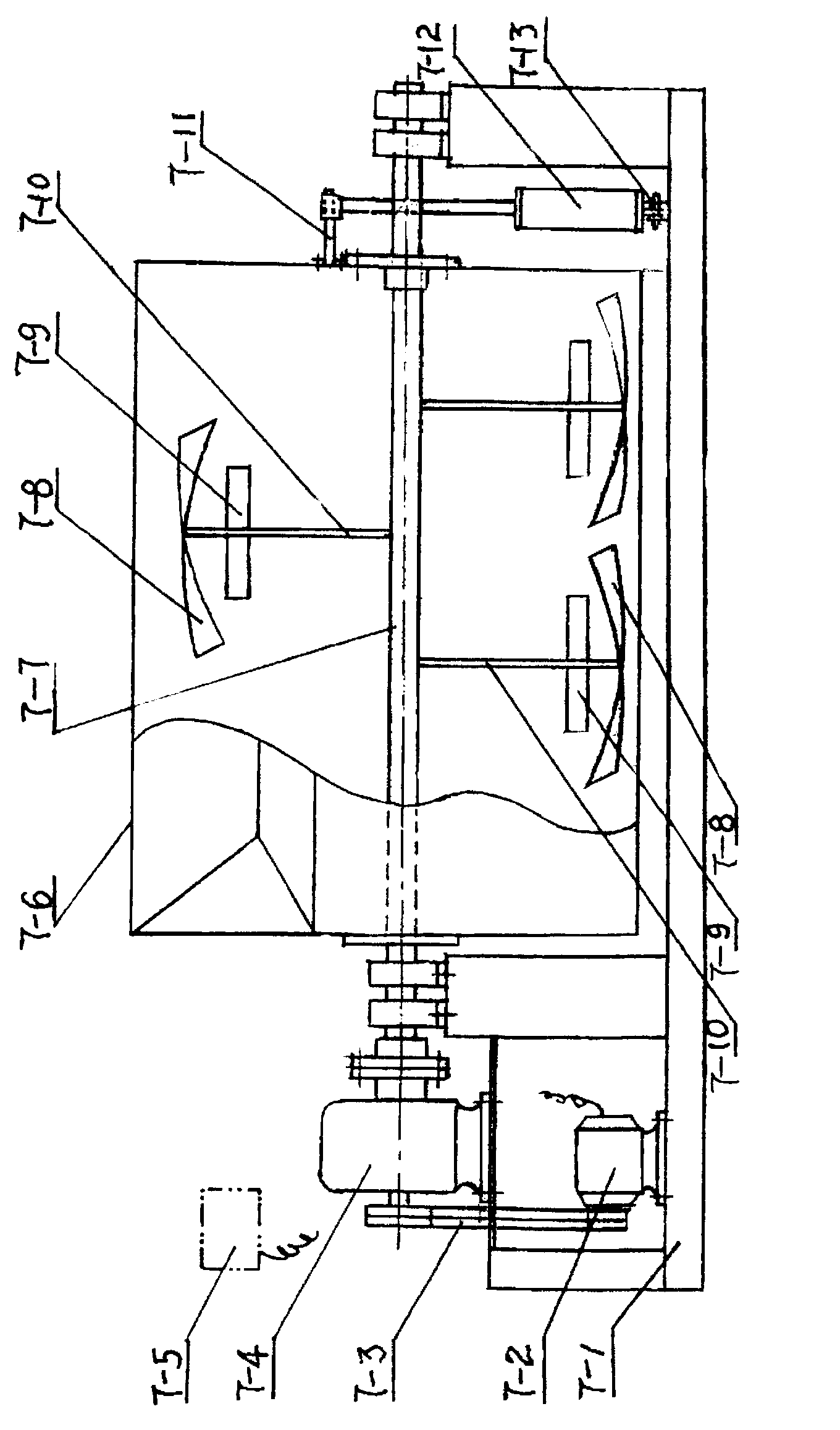

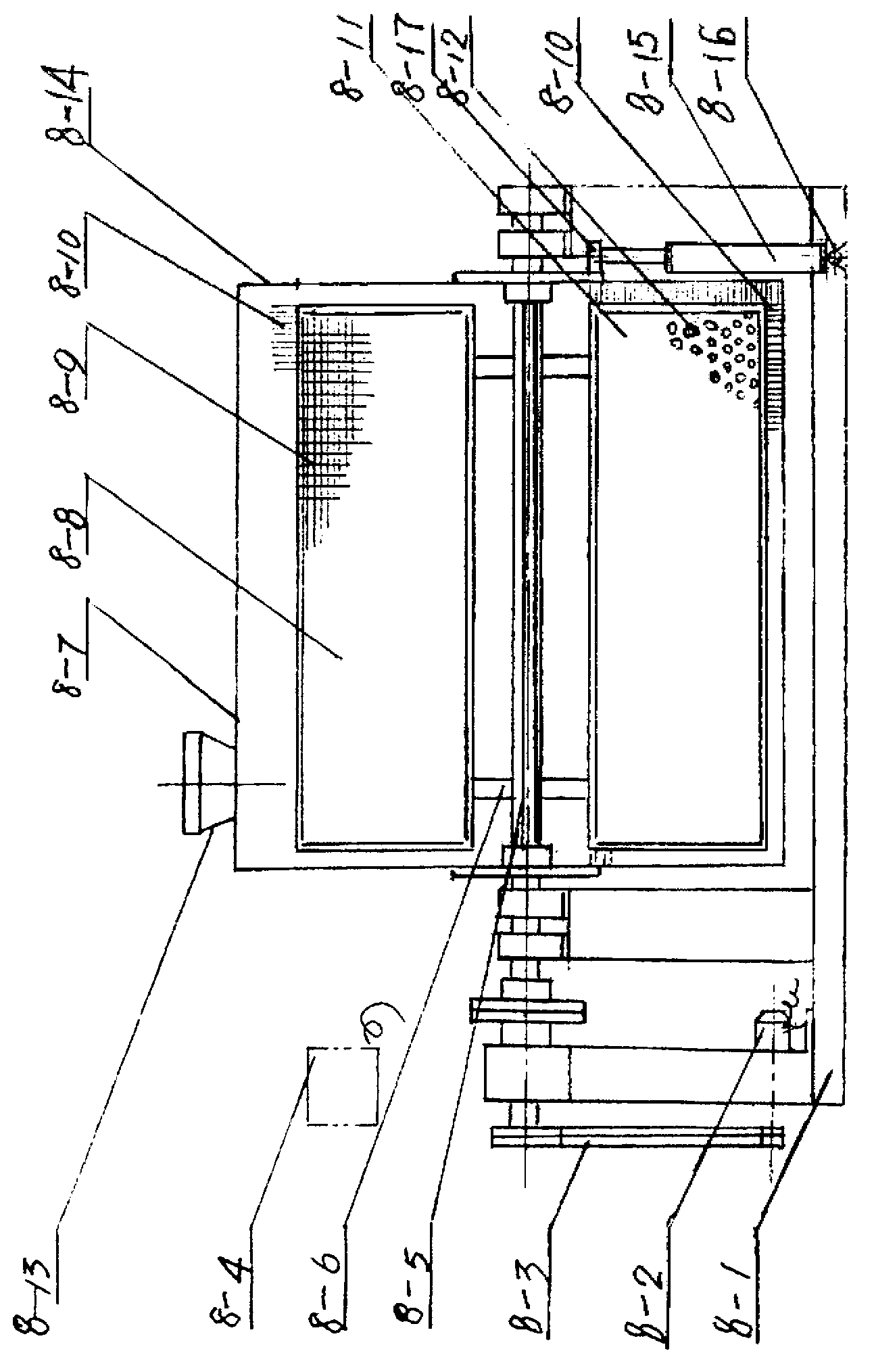

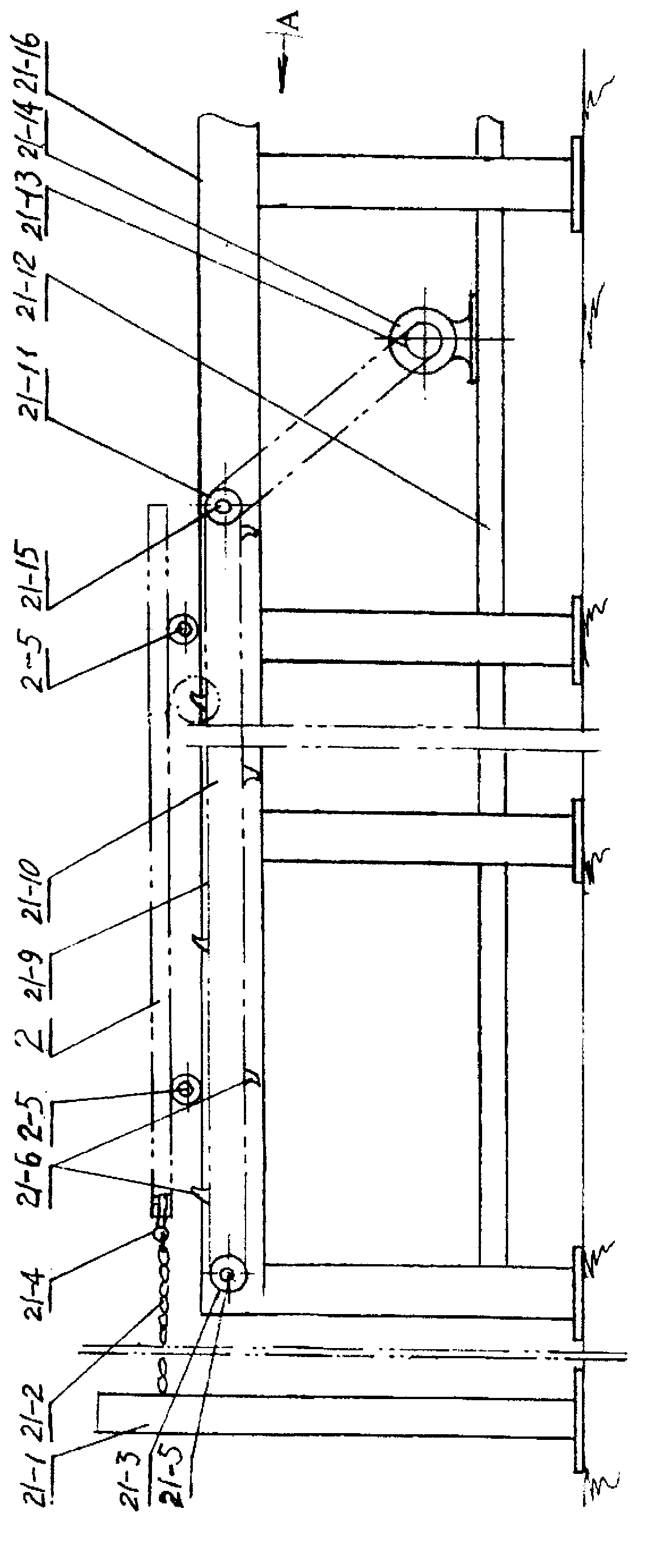

[0024] figure 1 , 2, 3, 4, 5, 6, and 7 show specific embodiments of the present invention, which are lightweight foamed concrete building board production lines for manufacturing hollow and solid strips, and are characterized in that: Technological process, a rectangular transportation track is provided on the construction ground, and the rectangular transportation track is composed of rack-type rails 1 on both sides and ferry rails 13 at both ends, and the rack-type rails 1 on the front side are sequentially composed of The demoulding treatment section and the pouring section are composed of several car body mold cars 2 moving along the track; the rack-type track 1 on the rear side is a curing section, and a curing furnace 19 is installed on the curing section. On the ferry section rails 13 at both ends, a manual ferry car 14 that moves along the rails is installed, and an elevator 15 driven by an electric chain drive is installed on the rack-type rail 1 outside the entrance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com