Detection device of appearance of mobile phone lens

A detection device and lens technology, used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

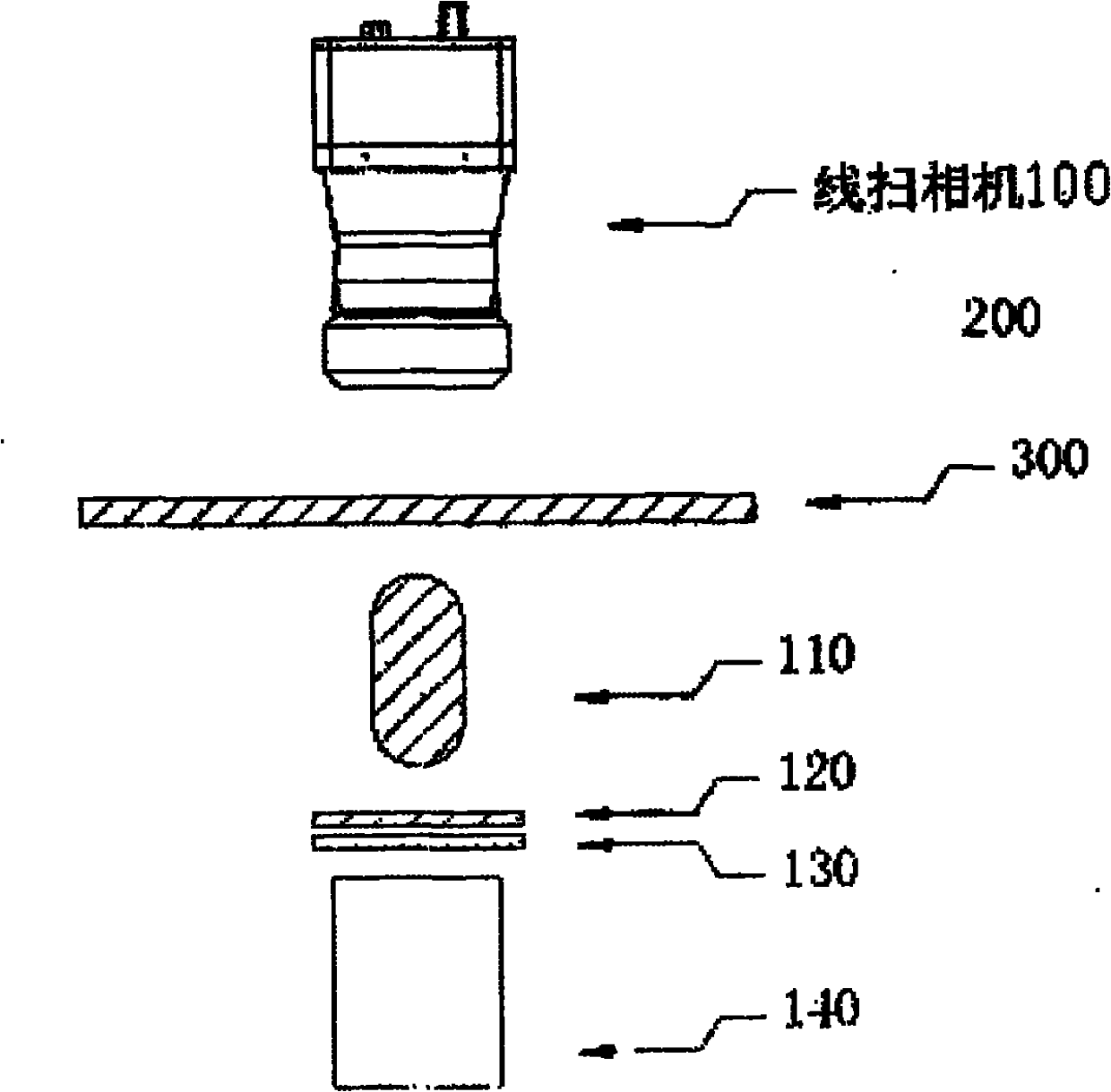

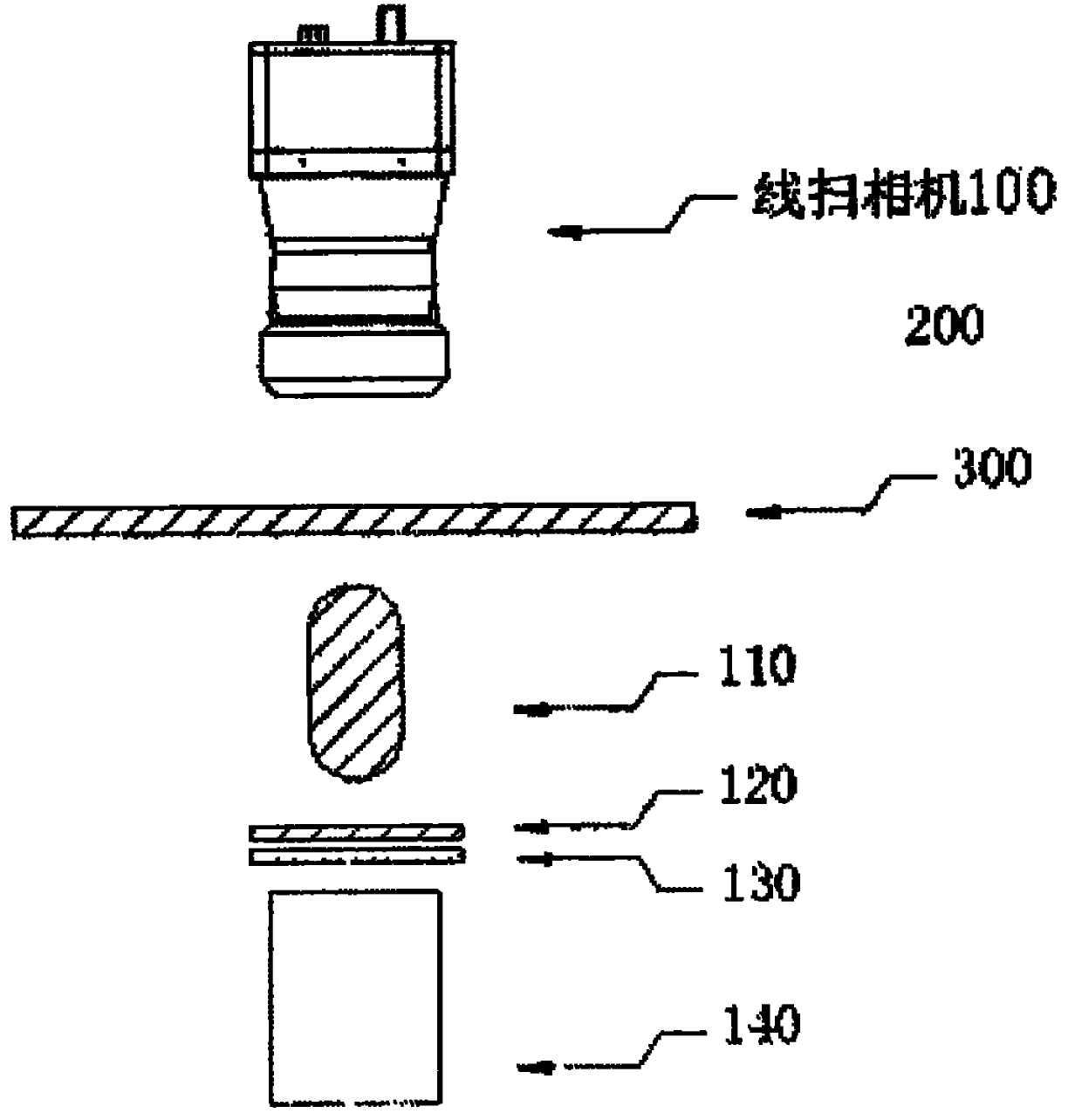

[0014] The features of the present invention will be described below with reference to the relevant drawings.

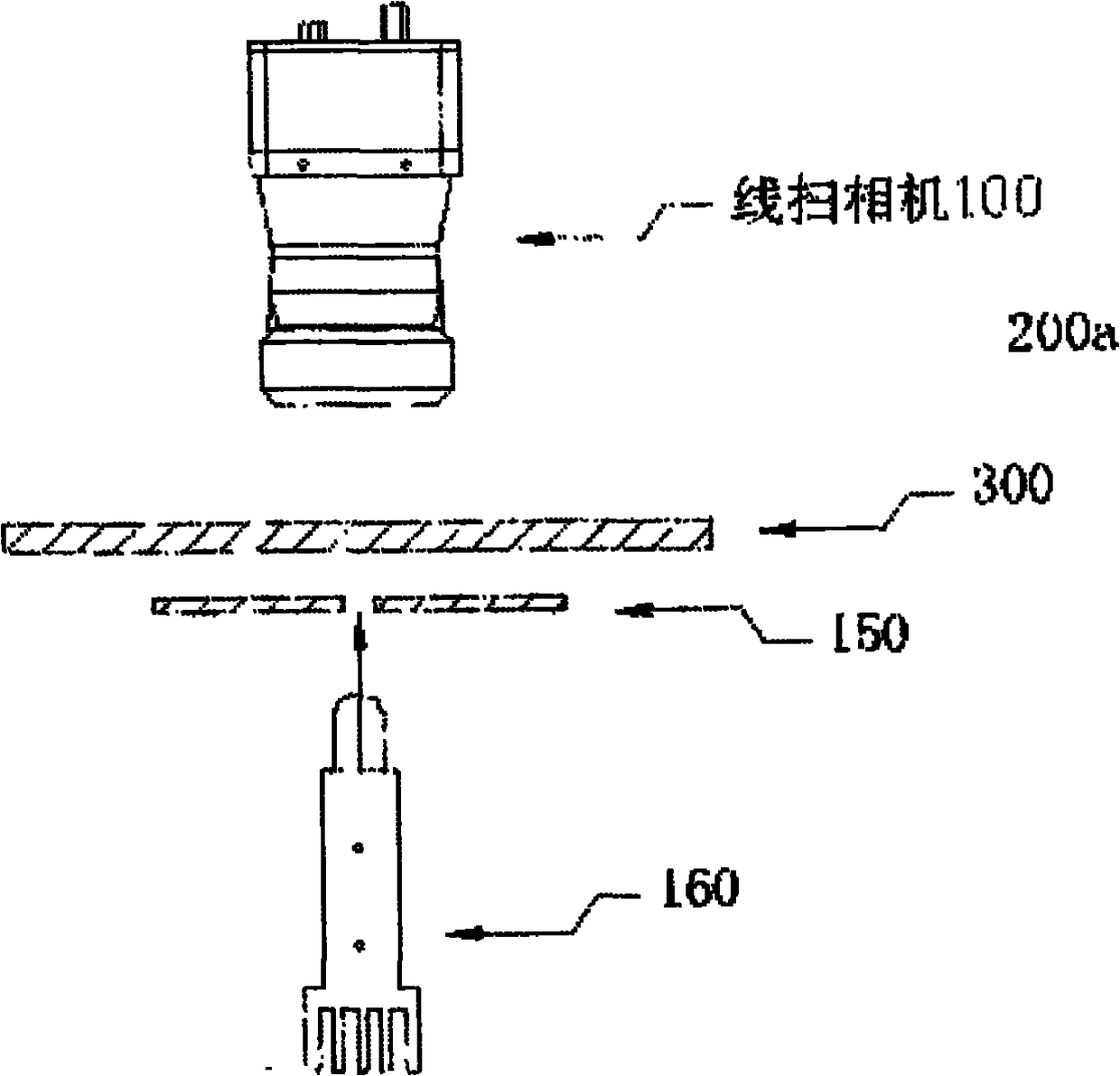

[0015] figure 1 It is a schematic diagram of a detection device according to an embodiment of the present invention, please refer to figure 1 , the detection device 200 of the present embodiment is suitable for detecting the lens 300 of a mobile phone, wherein there are a line-scan camera 100 positioned at the top of the lens, a strip convex mirror 110, a strip-shaped matte astigmatism sheet 120, a strip-shaped high-transmittance astigmatism sheet 130, and a strip-shaped astigmatism sheet 130. shaped highlight light source 140 .

[0016] The operation method of detecting the lens of the mobile phone is as follows: first light the bar light source, and when the lens of the mobile phone passes the camera at a constant speed by the transmission device, the camera is triggered to start scanning. The parallel light rays emitted by the strip-shaped high-brightness light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com