Coating thickness measuring probe

A technology for measuring probe and layer thickness, which is used in electrical/magnetic thickness measurement, electromagnetic measurement devices, etc., can solve problems such as unfavorable manufacturing, complex structure, etc., and achieve the effects of easy portability, small size, and stable measurement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

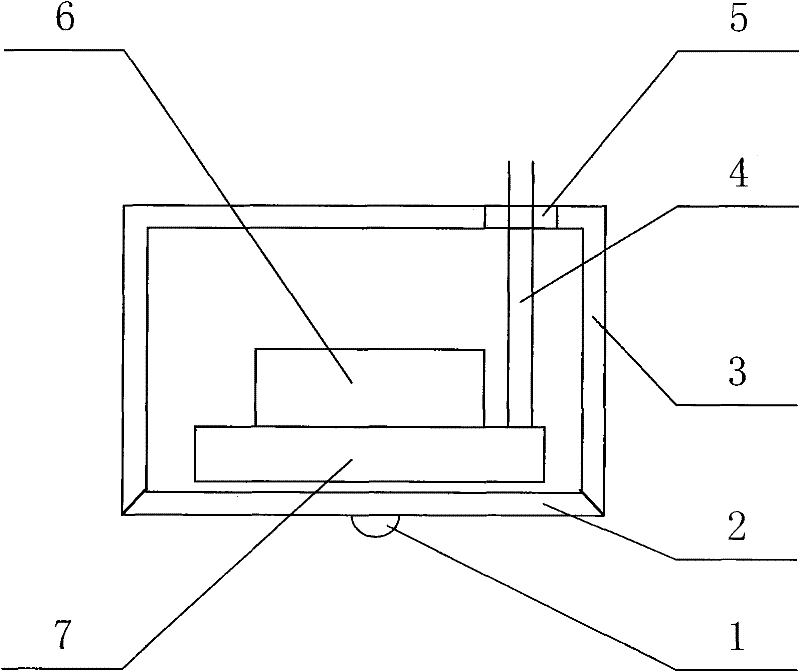

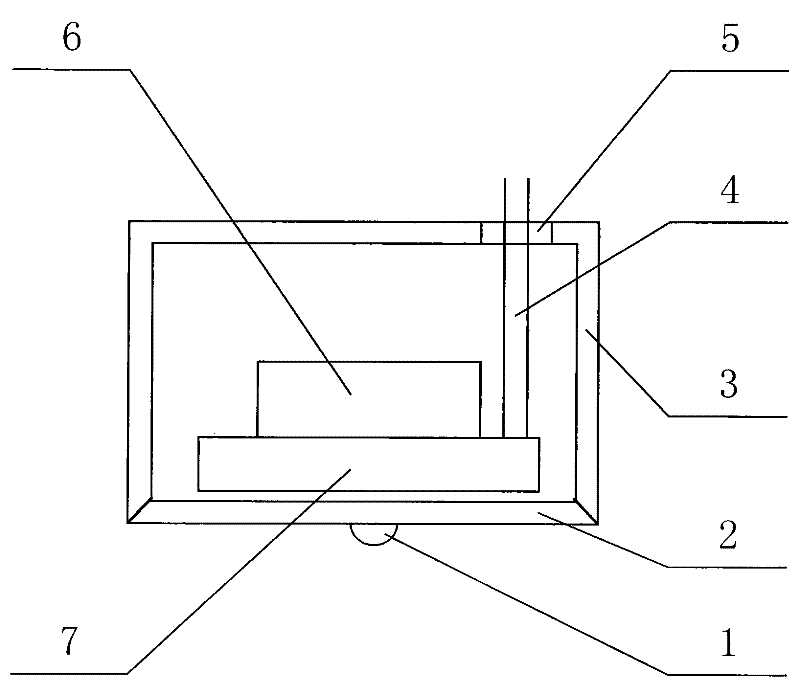

[0010] Such as figure 1 Shown is the structure schematic diagram of the coating thickness measuring probe of the utility model. The new-type coating thickness measuring probe includes a probe contact point 1, a probe housing end face 2, a probe housing 3, a wiring terminal 4 of a Hall element, an opening 5 of the rear end cover of the probe housing, a permanent magnet 6, and a Hall element 7; The probe housing 3 is a circular tube with a rear end cover, the rear end cover of the circular tube has an opening 5, and the terminal 4 of the Hall element is connected from the opening of the rear end cover of the circular tube. 5 through; the probe housing end face 2 is connected to the probe housing 3, the probe contact point 1 is fixed at the center of the probe housing end face 2, and the Hall element 7 is fixed on the On the end surface 2 of the probe housing mentioned above, the permanent magnet 6 is fixed on the Hall element 7 .

[0011] When the coating thickness measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com