Multi-flavor combined scented white spirit and preparation method thereof

A technology for light-flavored liquor and sauce-flavored liquor, which is applied in the preparation of alcoholic beverages, etc., can solve problems such as unproposed schemes and technical measures, and achieve full-bodied, easy-to-promote, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

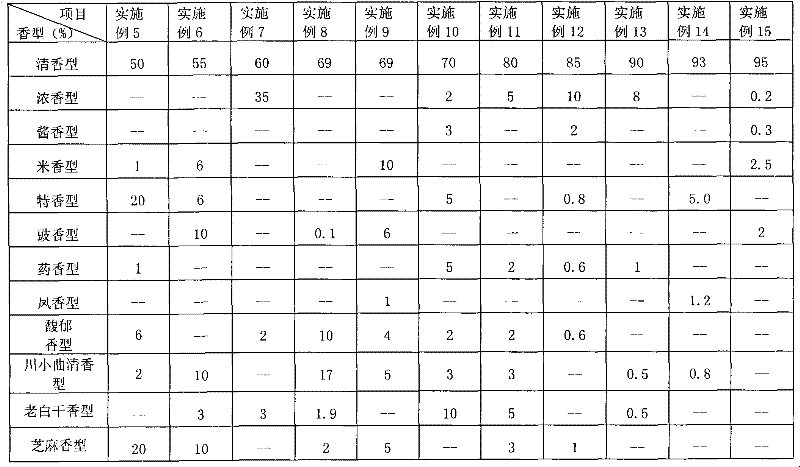

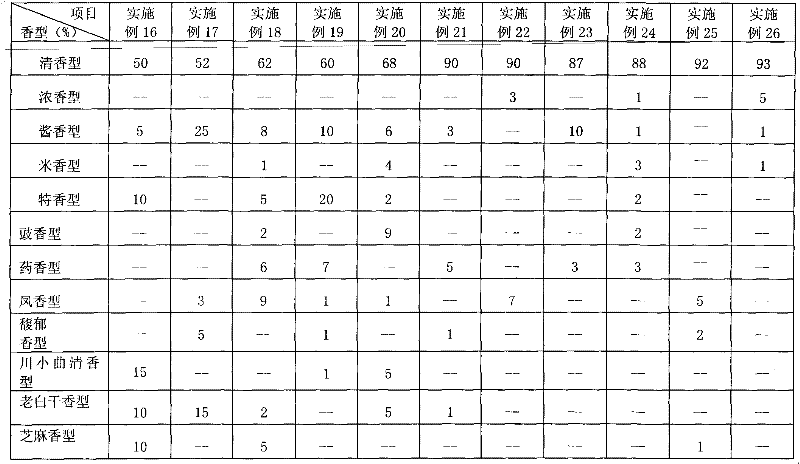

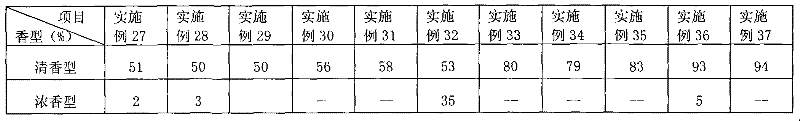

Examples

preparation example Construction

[0087] A preparation method of multi-flavor combined with fragrance-flavored wine, which consists of raw material pretreatment, stubble drying, lower koji, stacking fermentation, vat / pool preparation, large stubble entering vat / pool fermentation, large stubble leaving vat / pool distillation to extract wine, two It is composed of various processes of entering the vat / pool for fermentation, secondly leaving the vat / pool for distillation, aging, blending, seasoning and finalizing the shape, of which:

[0088] The raw material pretreatment process is:

[0089] ① Wash and soak the sorghum in hot water at 92°C to 95°C for 2 to 6 hours, drain the water, and let it dry naturally at room temperature for 1 to 4 hours, so that the grains can absorb water sufficiently and evenly, and the grains will not have a hard core when pinched by hand. The yield reaches 93% to 95%, the water content reaches 50% to 55%, and then dry steams at normal pressure for 60 to 100 minutes, so that the sorghum ...

Embodiment 1

[0109] The physical and chemical indicators related to the determination of total acids and total esters in the following examples are all based on acetic acid and ethyl acetate respectively.

[0110] 1. Raw materials

[0111] ① Grain raw materials

[0112] Sorghum, corn, glutinous rice, rice, and wheat are all commercially available.

[0113] ②Fermentation agent

[0114] Red yeast rice: commercially available, moisture 10.0%, esterification power 38.0 (mg / g), particle size 80% through a 40-mesh analytical sieve.

[0115] Fenxiang Daqu: Moisture 2%, saccharification power 810mg glucose / gram koji.hour, liquefaction power 0.9g starch / gram koji.60℃.hour, fermentation power 10g carbon dioxide / gram koji.25℃.48 hours.

[0116] Maotai-flavored Daqu: moisture 9%, saccharification power 125 mg glucose / gram koji.hour, liquefaction power 0.8mg starch / gram koji.60℃.hour, fermentability (carbon dioxide) 7g carbon dioxide / gram koji.25℃.48 hours.

[0117] ③flavored wine

[0118] Luzhou-...

Embodiment 2

[0137] 1. Raw materials

[0138] ① Grain raw materials

[0139] Commercially available: sorghum, corn, glutinous rice, rice, wheat.

[0140] ②Fermentation agent

[0141] Red yeast rice: moisture 10.0%, esterification power 45.0 mg / g, particle size 80% through 40-mesh analytical sieve.

[0142] Fenxiang Daqu: moisture 3%, saccharification power 900 mg glucose / gram koji.hour, liquefaction power 0.6g starch / gram koji.60℃.hour, fermentation power (carbon dioxide) 8g carbon dioxide / gram.25℃.48 hours.

[0143] Maotai-flavored Daqu: moisture 9%, saccharification power 210 mg glucose / gram koji.hour, liquefaction power 1.0mg starch / gram koji.60℃.hour, fermentation power (carbon dioxide) 9g carbon dioxide / gram koji.25℃.48 hours.

[0144] ③ Flavored wine:

[0145] Luzhou-flavor liquor, commercially available, sensory characteristics: clear and transparent, with the typical style of Luzhou-flavor liquor, strong cellar aroma, no abnormal smell. Total acid 0.4g / L, total ester 1.2g / L, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com