Process for recycling alkali and synchronously producing cement by roasting red mud

A technology of alkali recovery and roasting, which is applied in cement production, alkali metal hydroxide, sludge treatment through temperature control, etc., can solve the problems of red mud pollution and comprehensive utilization

Inactive Publication Date: 2011-11-09

骆群

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, none of the above technologies can fundamentally solve the problems of red mud pollution and comprehensive utilization.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] Kelt New Building Materials Co., Ltd. invested 2 million yuan to build a production line with a daily processing capacity of 60 tons of red mud in the production plant of Kelt New Building Materials Co., Ltd. in Baiyun District until the date of this patent application. Production is half built.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

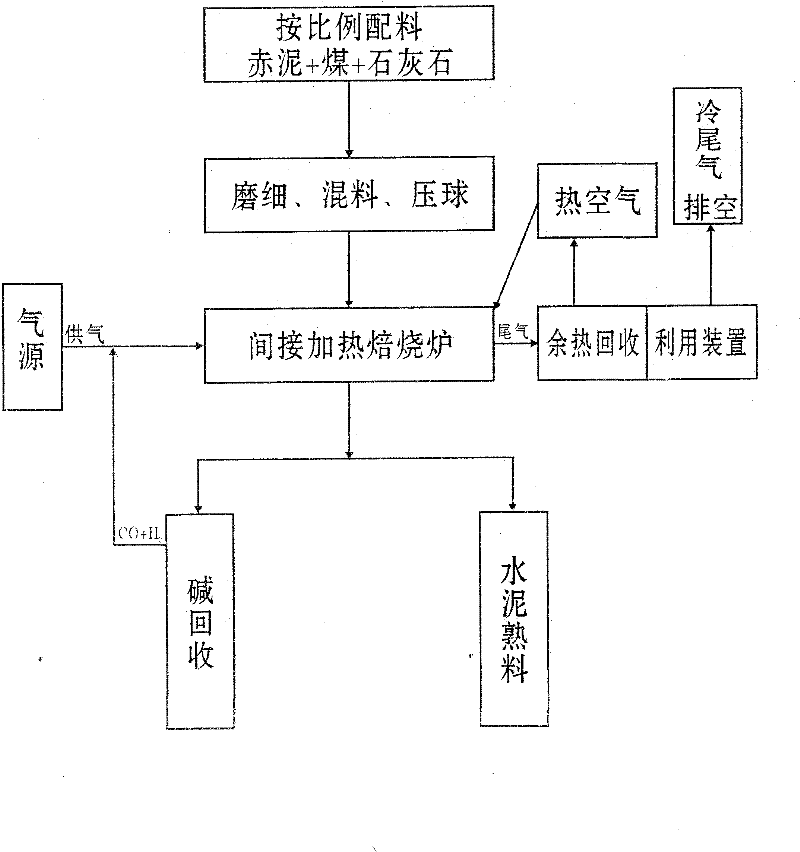

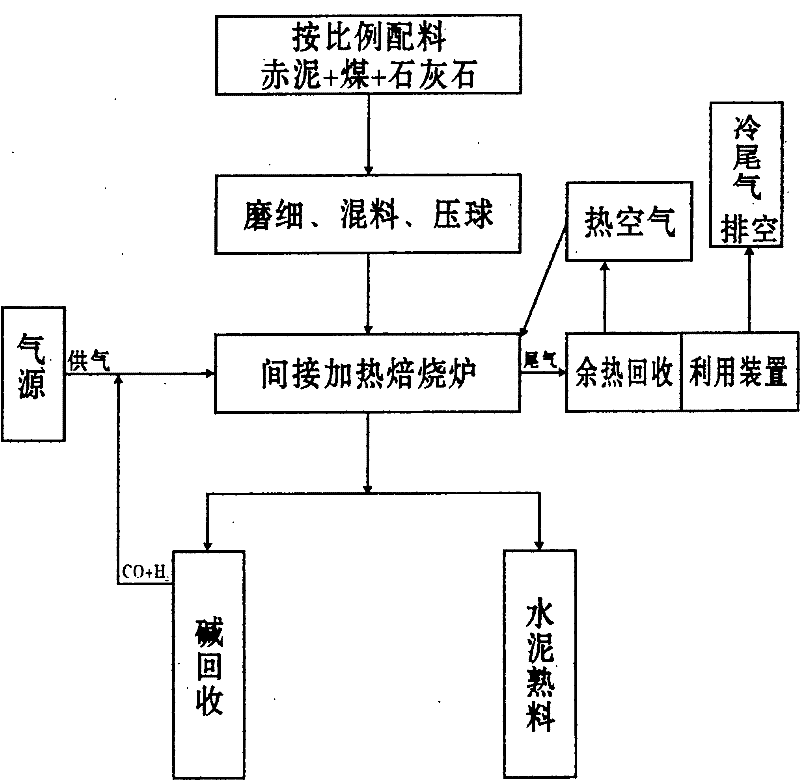

The invention discloses a process for recycling alkali and synchronously producing cement by roasting red mud, belonging to the field of aluminum industry production. 1.2-2.1 tons of red mud as a byproduct is produced while 1 ton of aluminum oxide is produced, wherein the red mud contains 5-7% of alkali which is large in amount and harmful to the environment; and the alkali is a significant environmental pollution source for restraining the development of the aluminum industry and the comprehensive utilization of the red mud and damaging the ecological environment. At present, removing and recycling of the alkali in the red mud is still a difficult problem in the world. The invention solves the problem on removing and recycling the alkali in the red mud, and realizes that the cement is synchronously produced while the alkali is removed and recycled; therefore, the zero emission of solid waste residuals is realized for aluminum oxide production enterprises. The process is crucially characterized in that a condition of oxygen-free strong reduction is created for separating the alkali in the red mud, thereby a reducing / decomposing reaction of Na2O(solid)+C(solid)=2Na(gas)+CO(gas) can be performed successfully. According to the process provided by the invention, the red mud is indirectly heated and is decomposed under an air-insulated and oxygen-free strong reduction condition to generate Na metal atoms; and the Na metal atoms are led to the outside of the furnace together with a byproduct CO, and enter a recycling tower to synthesize alkali (NaOH) with water. After the alkali is separated and recycled, the residues are synchronously sintered into cement.

Description

Technical field: [0001] In the field of aluminum industry, a large amount of waste is produced when the raw material of electrolytic aluminum—alumina is produced, because it contains about 10% Fe 2 o 3 And it is red, so it is called red mud, which is the object of the present invention. Therefore this patent should be included in the field of aluminum industry science and technology. Background technique: [0002] Red mud contains 5% to 7% alkali, mainly where NaOH is piled up, where there is no vegetation, and alkali seeps into the ground with rainwater, destroying the groundwater system, and causing fish and shrimp to disappear when it flows into rivers. The amount of red mud is large, which is 1.5 to 2.1 times that of alumina production. my country's current alumina production capacity has reached more than 36 million tons, and the amount of red mud has at least 50 million tons, which occupies a large amount of land. Due to the existence of alkali, the comprehensive u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/18C04B7/24C01D1/04

CPCY02P40/10

Inventor 骆群

Owner 骆群

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com