Sleeve for connection and washer for supporting used reacting force and connecting structure

A technology of connection structure and reaction force, applied in the direction of connection members, washers, wrenches, etc., can solve problems such as low operation efficiency and achieve the effect of less stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, the sleeve for nut connection, the washer for receiving the reaction force used therein, and the connection structure capable of preventing co-rotation will be described in detail with reference to the accompanying drawings.

[0070] (Example)

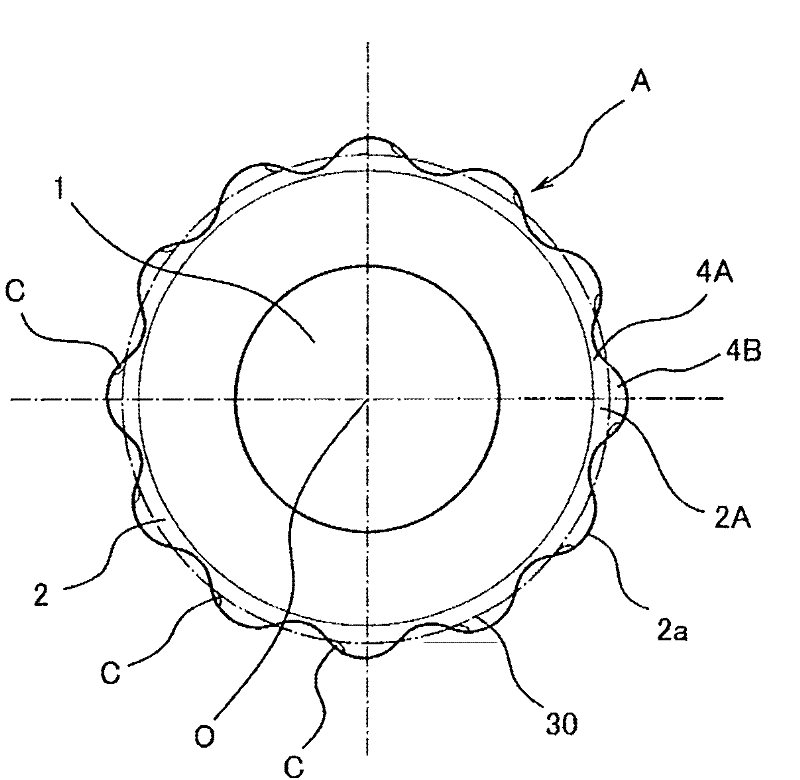

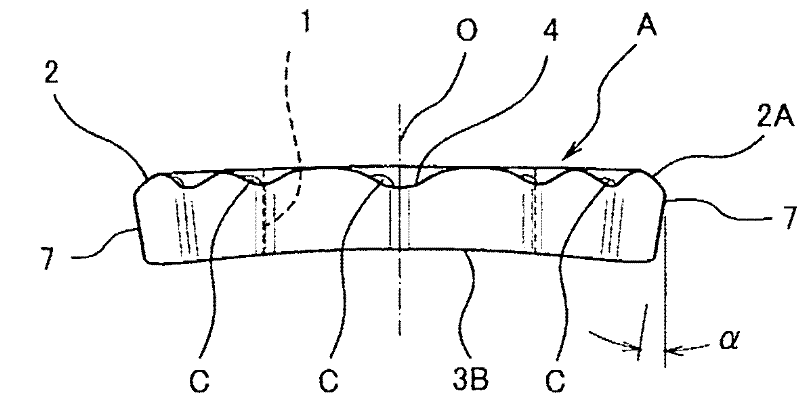

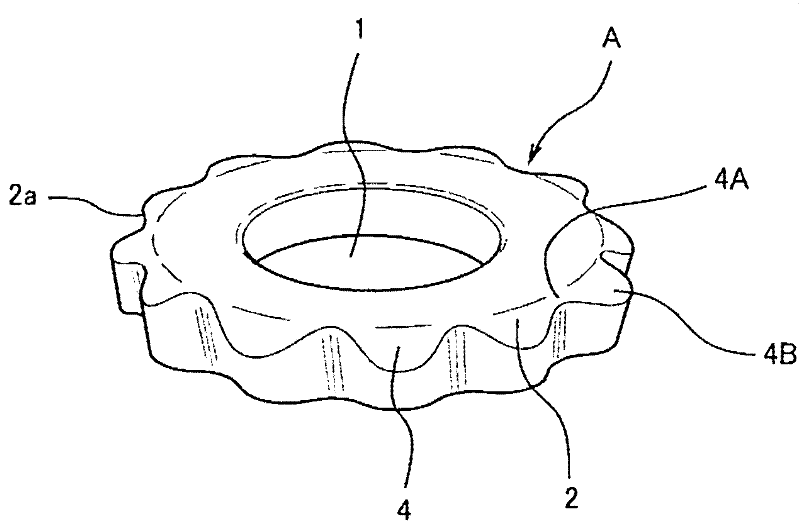

[0071] exist figure 1 Among them, A is the washer for receiving the reaction force, such as figure 1 As shown, in a plan view, the central portion of the washer A is formed with a through hole 1 for the bolt shaft to pass through, and the size of the washer A is compared with the outer edge portion 2 Figure 8 The outer edge 10a of the illustrated nut 10 (or bolt head 15h) protrudes toward the outer diameter side.

[0072] and, if figure 1 As shown, the shape of the outer periphery (outer edge) 2a of the washer A is such that, in a plan view, a virtual reference circle 30 takes the center point O of the washer A as the center, and forms a concave portion in the radial direction around the virtual reference circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com