Tensile high-speed data cable

A high-speed data, stretch-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large stretching and extrusion force, unstable signal transmission, loss of transmission function, etc., and achieve small elongation at break, Effects of improving the fatigue resistance and bending properties and increasing the ability to resist external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

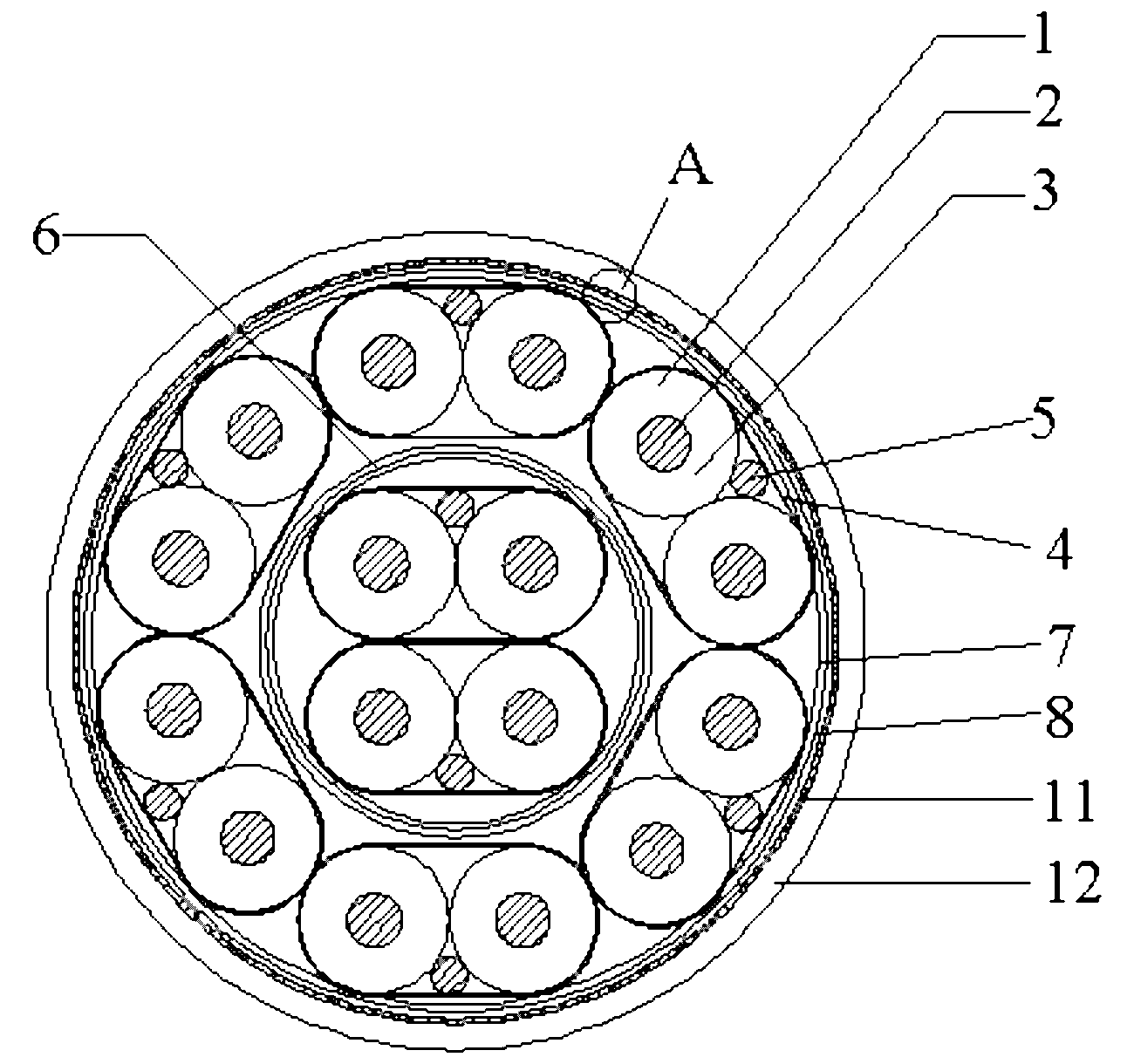

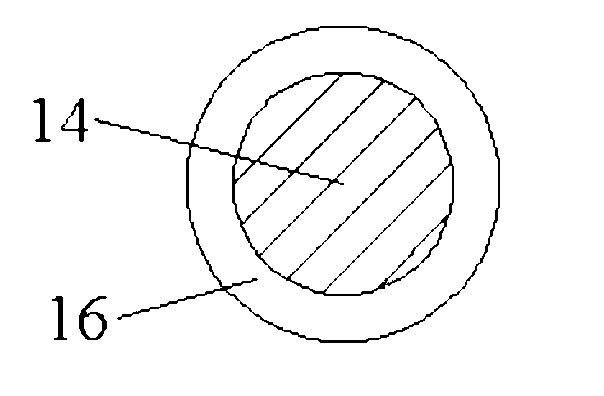

[0027] Embodiment: A stretch-resistant high-speed data cable, comprising: eight pairs of copper wires 1, the copper wires 2 are covered with a first insulating layer 3; each of the copper wires 2 is coated with a first Aluminum-plastic composite layer 4; there is a current guide wire 5 as a ground wire between the first aluminum-plastic composite layer 4 and the pair of copper wires 1;

[0028] A second insulating layer 6 covers two pairs of copper wires in the eight pairs of copper wires 1, and the other six pairs of copper wires in the eight pairs of copper wires 1 are attached to the second insulating layer. layer 6;

[0029] A polyester tape layer 7 is wrapped on the other six pairs of copper wires among the eight pairs of copper wires;

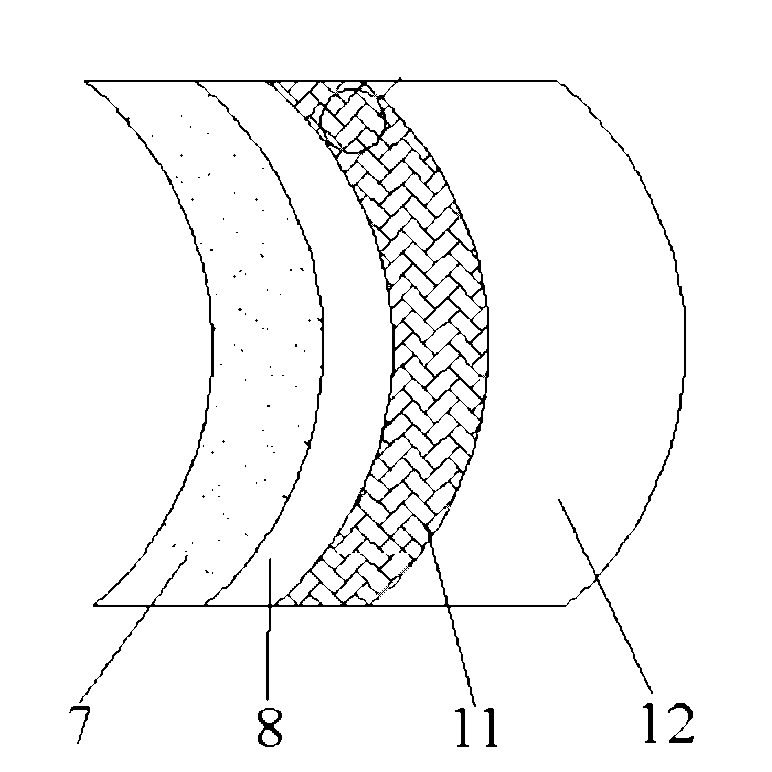

[0030] A second aluminum-plastic composite layer 8 is coated on the polyester tape layer 7, and the second aluminum-plastic composite layer 8 is composed of a polyester film layer 9 and an aluminum film layer 10 coated on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com