Lens module

A lens module and lens barrel technology, applied in the field of optical systems, can solve problems such as difficult focusing, different locking force, and thread wear, so as to achieve uniform locking force and avoid difficult focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

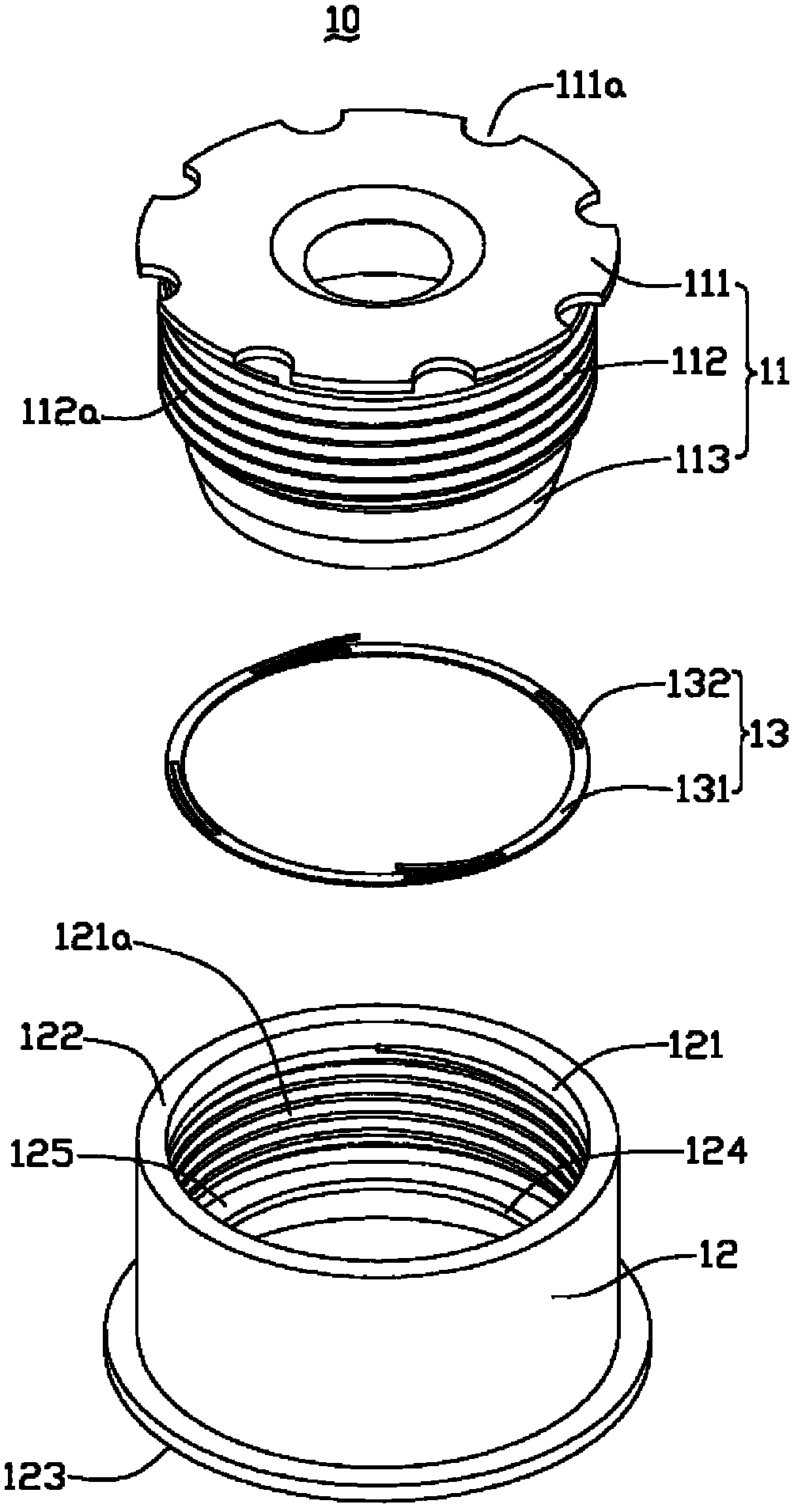

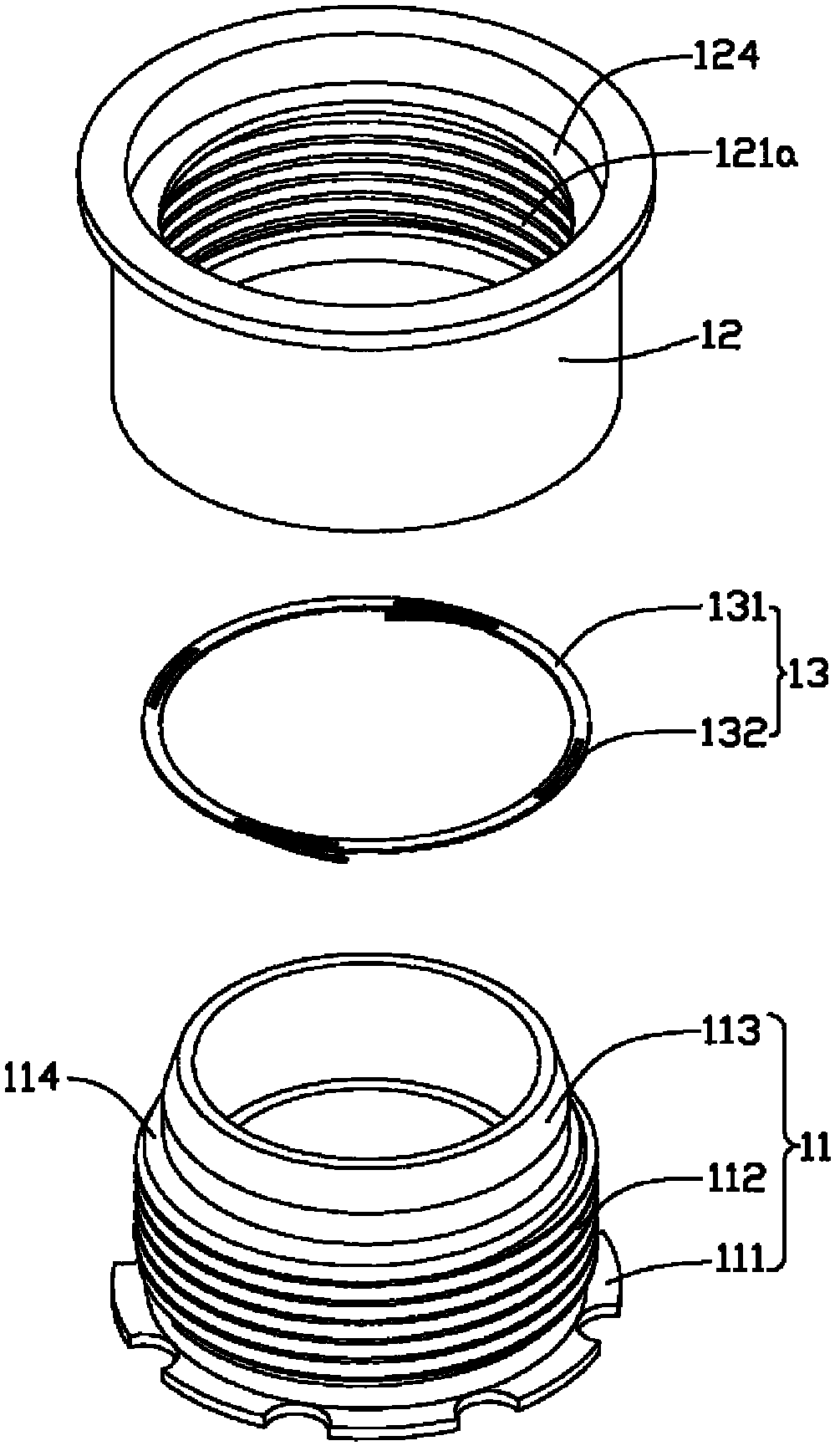

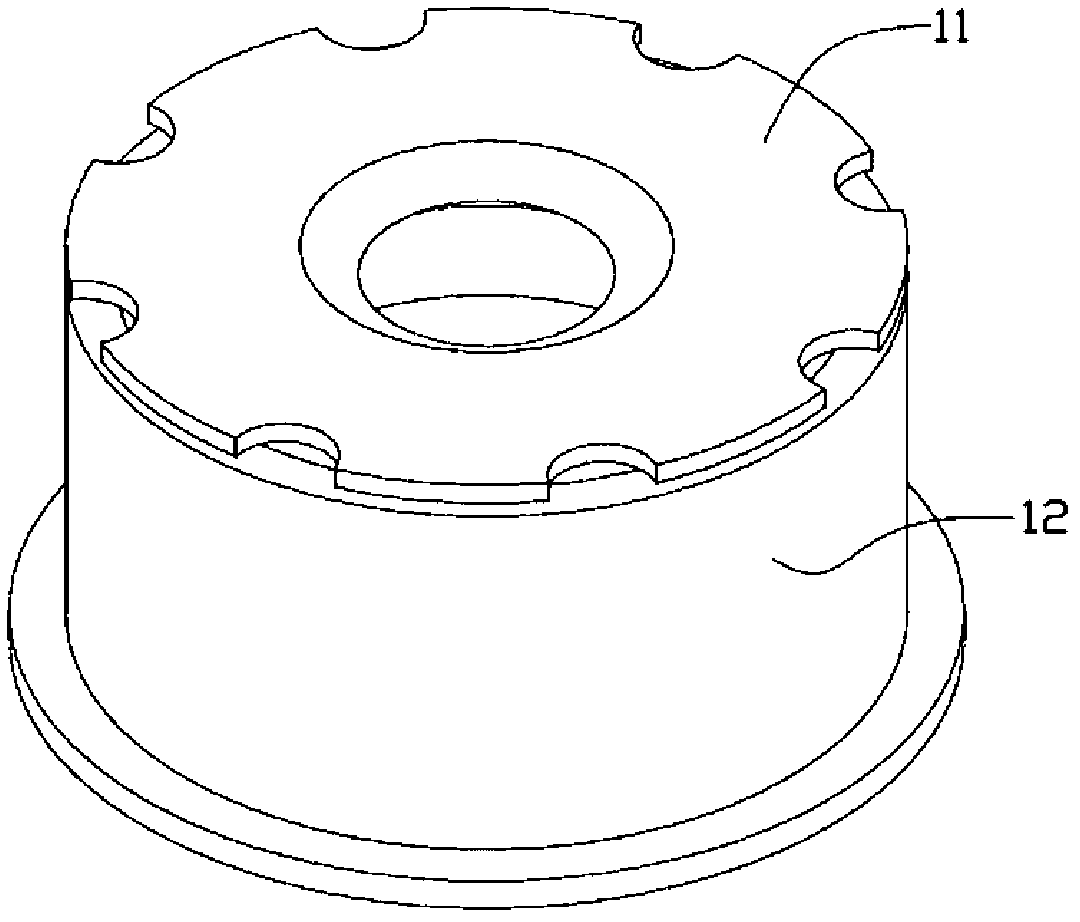

[0013] Such as Figure 1 to Figure 4 As shown, a lens module 10 provided by an embodiment of the present invention includes a lens barrel 11 , a lens base 12 and an elastic element 13 .

[0014] Both ends of the lens barrel 11 are open and connected, and the lens barrel 11 accommodates elements such as a lens group, a spacer ring, and a filter (not shown in the figure). The lens barrel 11 sequentially includes an actuating part 111 , a shaft connecting part 112 and an extending part 113 connected to each other from the object side to the image side. In this embodiment, the actuating part 111 is disc-shaped, the shaft connection part 112 is cylindrical shaft-shaped, and the outer diameter of the actuation part 111 is larger than the outer diameter of the shaft connection part 112 . A plurality of semicircular grooves 111 a are evenly spaced on the edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com