Method for visually and intelligently identifying internal defects of GIS (Geographic Information System) equipment

A technology of internal defect and intelligent identification, applied in the direction of material analysis using radiation, can solve problems such as difficult to predict, fall off, identify nature and position, and achieve the effect of improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for visual intelligent identification of internal defects of GIS equipment according to the present invention will be described in detail below in conjunction with the accompanying drawings.

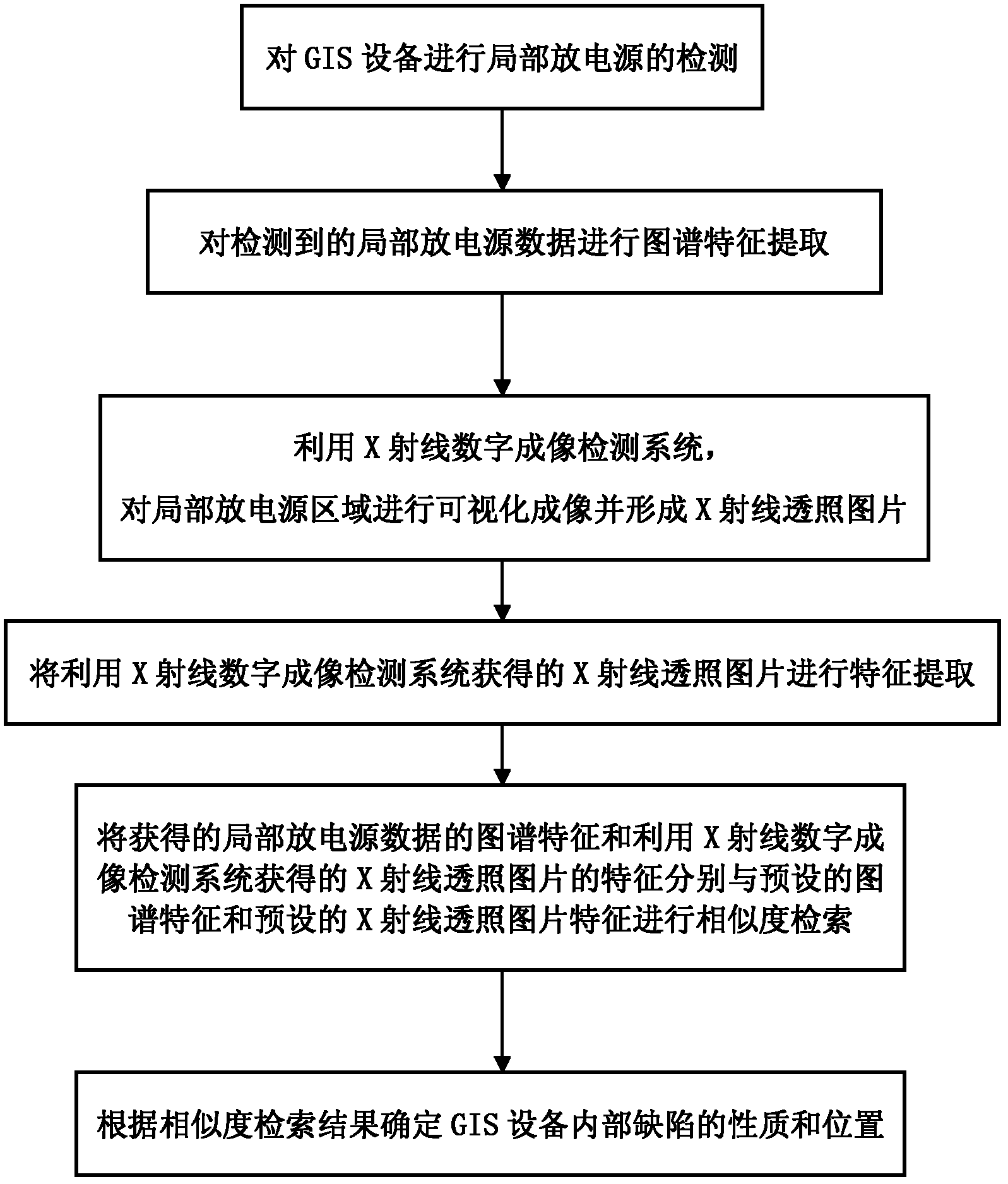

[0031] The flow of the method of visual intelligent identification of internal defects of GIS equipment is as follows: figure 1 shown. The method comprises the steps of:

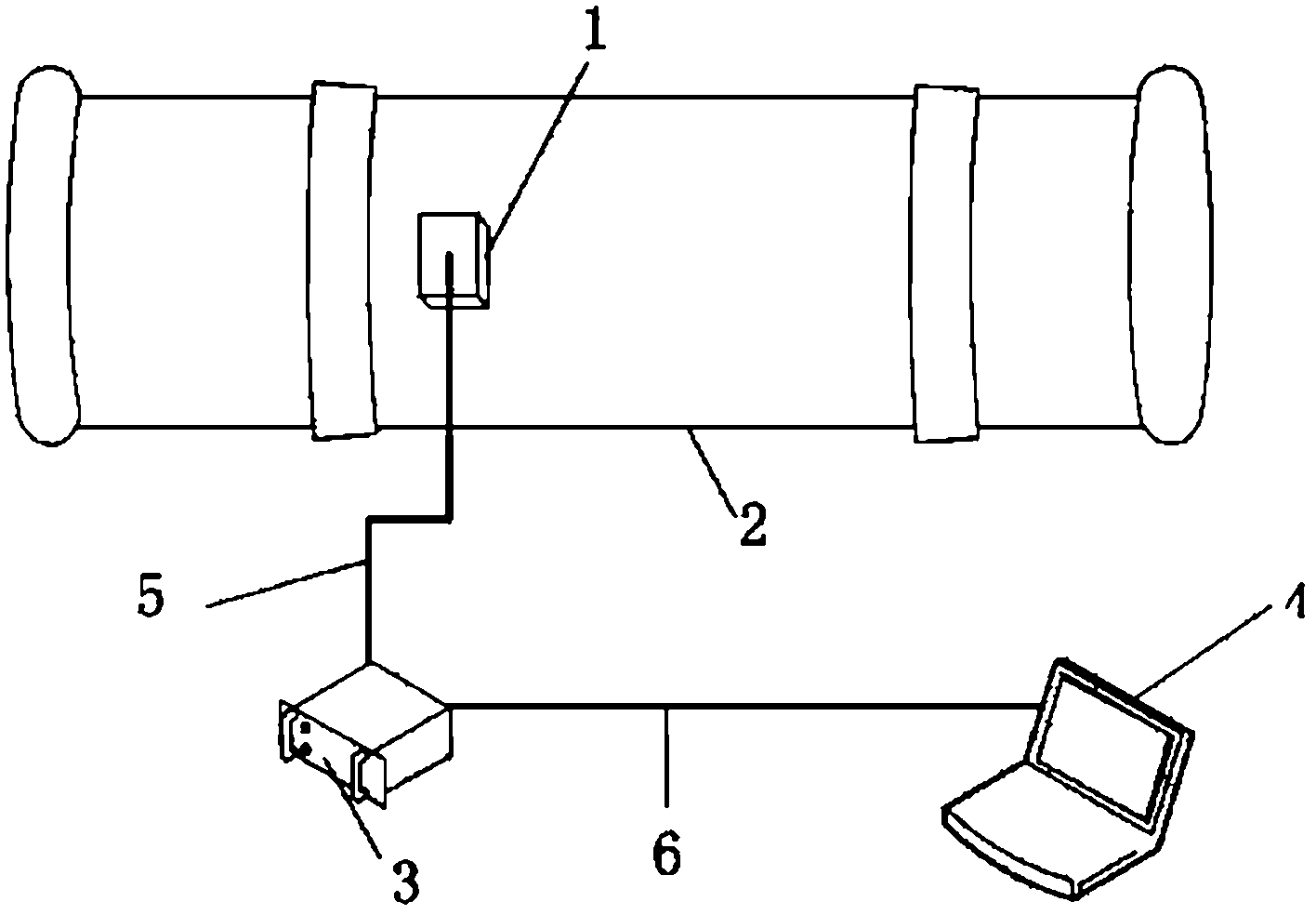

[0032] A. Detection of partial discharge source on GIS equipment;

[0033] B. Perform spectral feature extraction on the detected partial discharge source data;

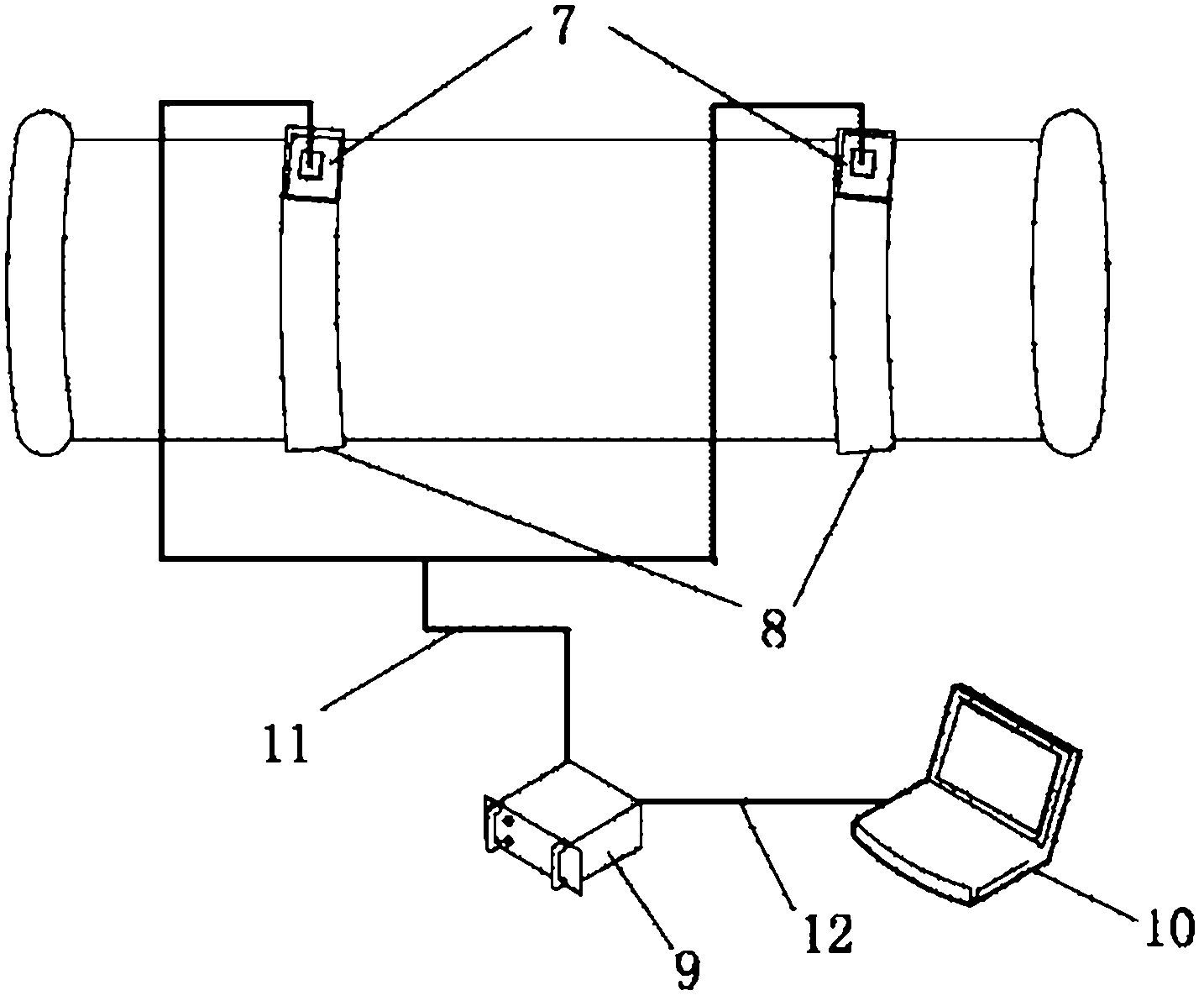

[0034] C. Use the X-ray digital imaging detection system to visually image the area of the partial discharge source and form an X-ray transillumination picture;

[0035] D. Carry out feature extraction from the X-ray transillumination pictures obtained by the X-ray digital imaging detection system;

[0036] E. Retrieve the similarity between the spectral features of the obtained partial discharge source data and the features of the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com