High-efficiency, sub-control and phase-change heat exchange system and method

A phase-change heat and high-efficiency technology, applied in the field of enhanced heat transfer, can solve the problems of reducing the heat exchange capacity of phase-change heat exchangers, reducing equipment life, and subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

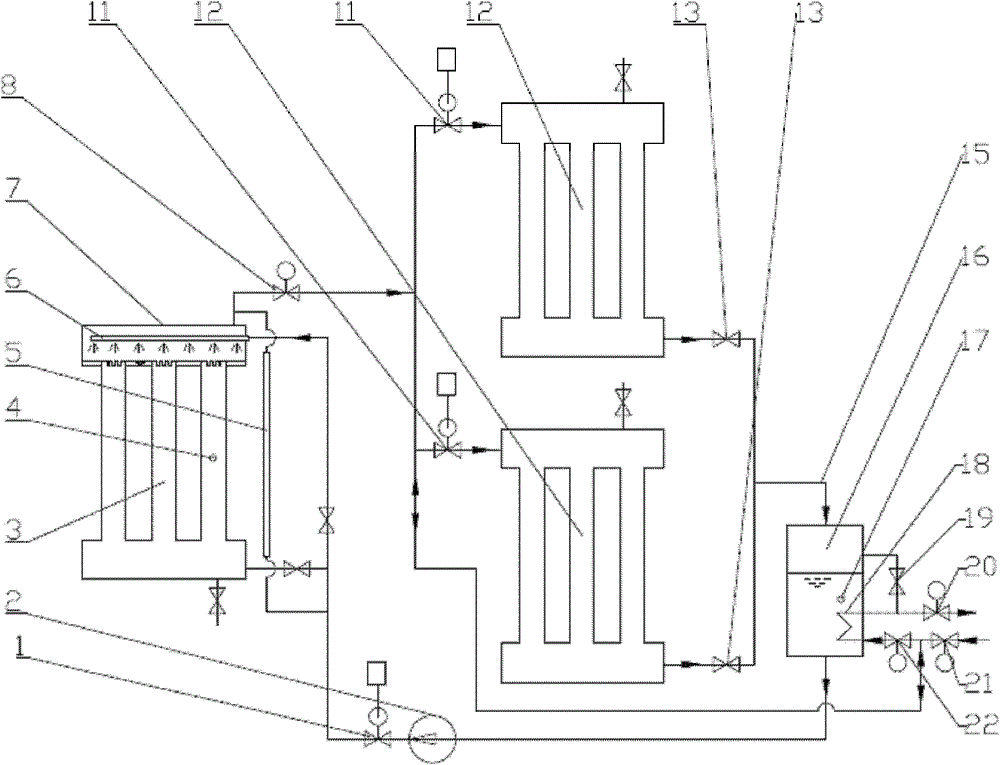

[0065] The system of a new type of split-controlled phase-change heat technology proposed by the present invention is shown in the accompanying drawings, and the main equipment includes:

[0066] Liquid flow regulating valve 1; circulating pump 2; heat source heat exchanger 3; internal temperature sensor 4 of heat source heat exchanger; liquid level sensor 5; liquid distribution pipe in upper header 6; upper header 7 of heat source heat exchanger; steam mother Pipe opening and closing valve 8; air flow regulating valve 11; cold source heat exchanger 12; cold source heat exchanger outlet valve 13; condensate main pipe 15; liquid storage tank 16; liquid storage tank condensate temperature sensor 17; condensate Heater 18; Unicom valve 19; External steam source return valve 20; External steam source supply valve 21; Condensate heating steam valve 22.

[0067] The system working process and characteristics of the sub-controlled phase-change heat technology of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com