Low temperature protection device for metal heat exchange tube of preheater

A low-temperature protection and heat exchange tube technology, which is applied in heat exchange equipment, damage protection, lighting and heating equipment, etc. Heat recovery efficiency and service life, reduced energy consumption, and the effect of avoiding acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

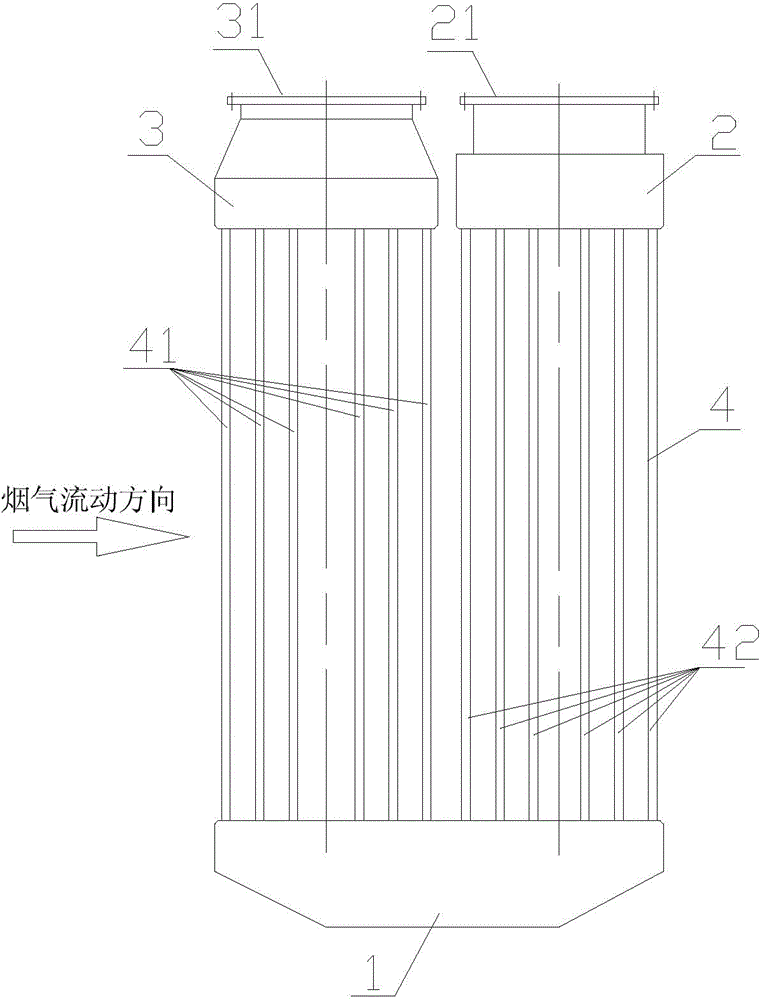

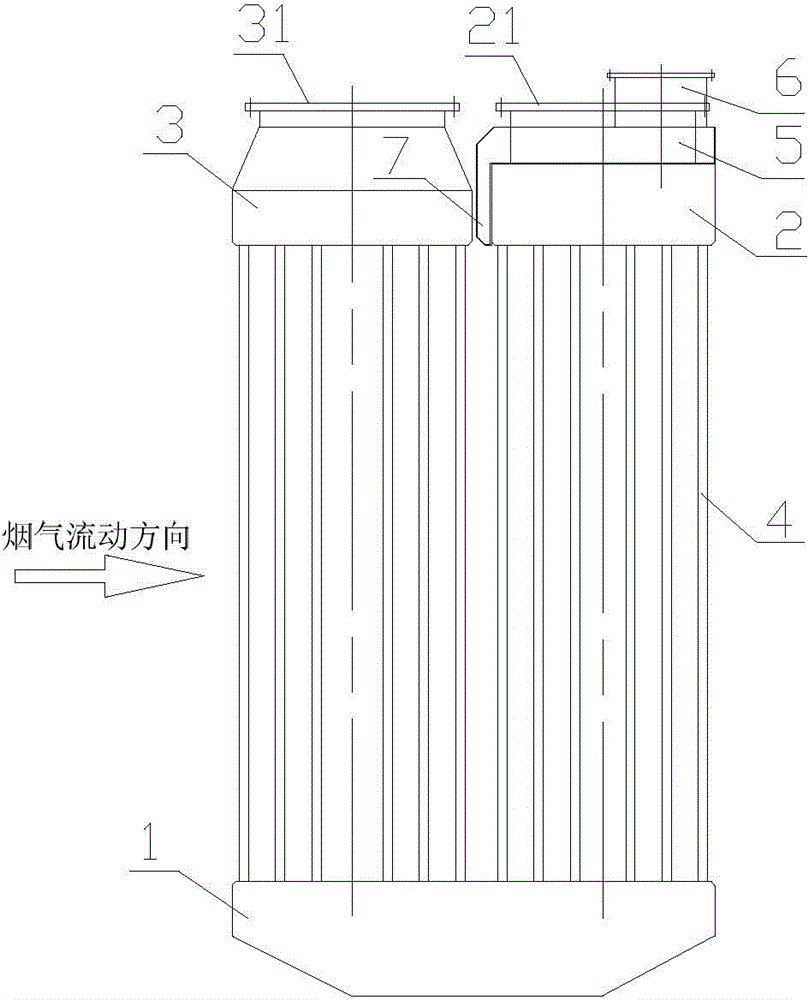

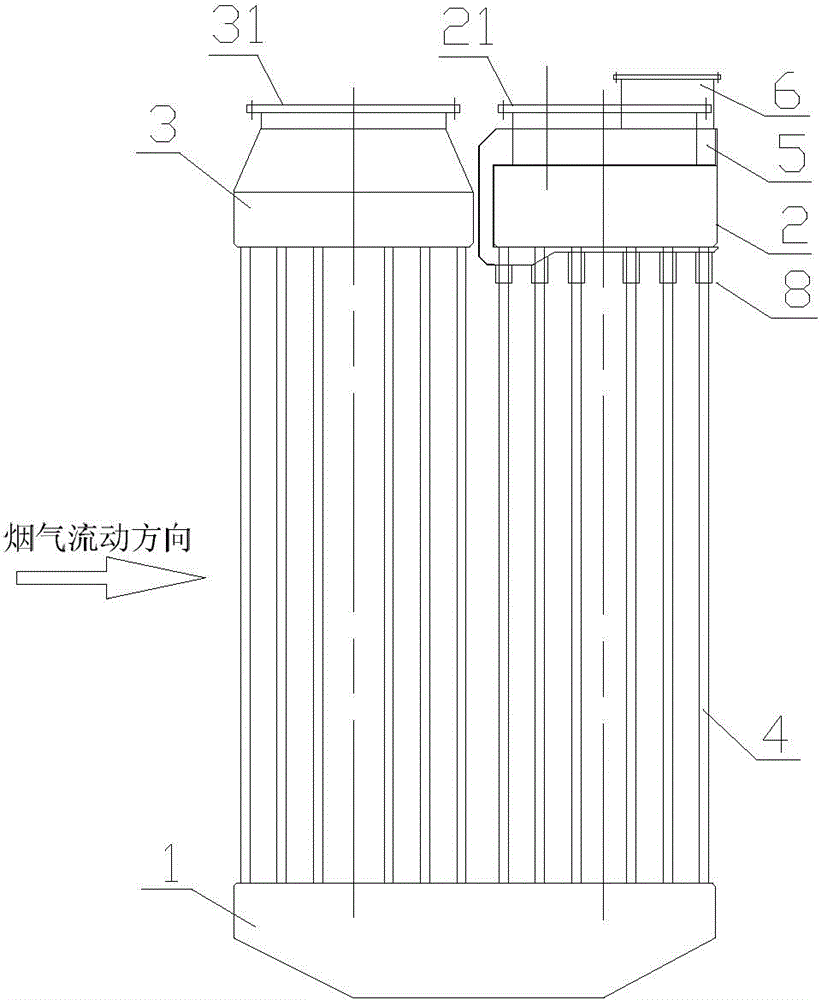

[0011] Such as figure 2 As shown, the low temperature protection device for the metal heat exchange tube of the preheater of the present invention includes an air bottom connection box 1, an air input header 2, an air output header 3, and a plurality of metal heat exchange tubes 4, and the plurality of metal heat exchange tubes 4 The air input header 2, the air output header 3, and the air bottom connection box 1 are arranged in parallel intervals, and are respectively connected to the air input header 2 and the air bottom connection box 1, and the air bottom connection box 1 and the air output header. 3. The air input header 2 and the air output header 3 are respectively provided with an air input interface 21 and an air output interface 31. The device also includes a warm air header 5 and a warm air interface 6. The warm air header 5 Sleeved on the top of the air input header 2 and the bottom of one side of the warm air header 5 faces the plurality of metal heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com