Method for constructing super-hydrophobic membrane on surface of copper matrix

A copper-based, super-hydrophobic technology, applied in the field of building super-hydrophobic films, can solve the problems of cumbersome and complicated super-hydrophobic surface steps, high toxicity of raw materials, etc., and achieve good super-hydrophobicity, simple equipment and process, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

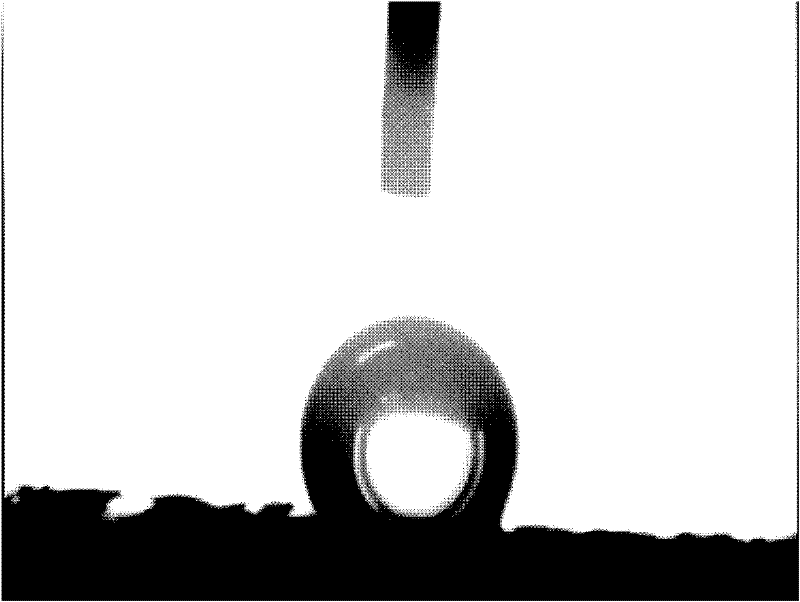

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: in this embodiment, a method for constructing a super-hydrophobic film on the surface of a copper substrate is realized through the following steps: 1. Putting the copper substrate into hydrochloric acid with a mass concentration of 0.1% to 30% or a mass concentration of 0.1% Soak in ~70% sulfuric acid or a mixture of equal volumes of the above two acids for 0.2 to 120 minutes to remove oxides on the surface of the copper substrate, then wash the copper substrate with deionized water for 1 to 3 times, and then rinse with ethanol for 1 to 3 times. 3 times to obtain a clean copper substrate; 2. Dissolve silver nitrate in methanol, ethanol or acetone to obtain solution A; then add a carboxylic acid with 9 to 20 carbon atoms in the main chain to solution A to dissolve it to obtain solution B ; In solution B, the concentration of silver nitrate is 1~30mmol / L, and the concentration of carboxylic acid is 1~40mmol / L; 3. Put the clean copper substrate obt...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of hydrochloric acid in step 1 is 1%-25%, the mass concentration of sulfuric acid is 1%-60%, and the soaking time is 0.5-100min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment differs from Embodiment 1 in that the mass concentration of hydrochloric acid described in step 1 is 10%, the mass concentration of sulfuric acid is 5%, and the soaking time is 50 minutes. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com