Method for adding medical stone for fermentation in production of white liquor

A medical stone and liquor technology, applied in the field of food processing, can solve problems such as unbalanced fermentation strains, great influence on wine quality, and complicated operability, so as to increase the quantity and type, increase the yield of wine, and optimize the combination structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

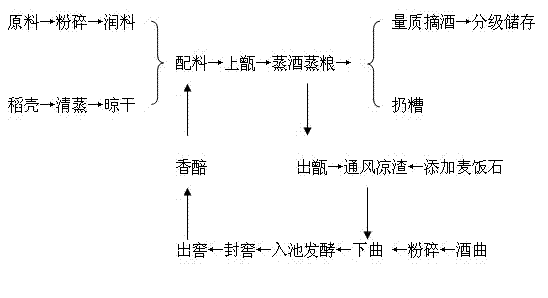

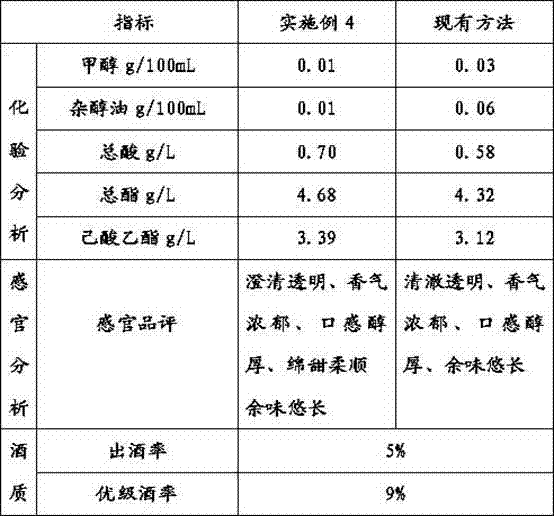

Embodiment 1

[0018] After the steamed grain is gelatinized, the brewing material is sprinkled with medical stone during the ventilation and cooling process. The fineness of the medical stone is 600 mesh. The added medical stone accounts for 0.5% of the weight of the wine grains. The stones are mixed evenly and put into the pond for fermentation. The traditional liquor brewing process is adopted, and the cellar is released after a 60-day fermentation period. The process flow chart is shown in the attached drawing. The obtained original wine has an increase of about 10% in the output of high-grade wine and wine yield; the content of beneficial bacteria in the pit mud increases, and the growth of the bacterial group is active; the produced original wine is clear and transparent, with a strong grain aroma, mellow taste, Sweet and supple. The difference between the existing method and the processing method of this embodiment is that the existing method does not add medical stones to process th...

Embodiment 2

[0023] After the steamed grain is gelatinized, the brewing material is sprinkled with medical stone during the process of cooling the dregs. The fineness of the medical stone is 800 mesh, and the added medical stone accounts for 1% of the weight of the wine grains. Mix evenly and put into the tank for fermentation. The traditional liquor brewing process is adopted, and the cellar is released after a 60-day fermentation period. The process flow chart is shown in the attached drawing. The obtained original wine has an increase of about 10% in the output of high-grade wine and wine yield; the content of beneficial bacteria in the pit mud increases, and the growth of the bacterial group is active; the produced original wine is clear and transparent, with a strong grain aroma, mellow taste, Sweet and supple. The difference between the existing method and the processing method of this embodiment is that the existing method does not add medical stones to the liquor obtained by proce...

Embodiment 3

[0027] After the steamed grain is gelatinized, the brewing material is sprinkled with medical stone during the process of cooling the dregs. The fineness of the medical stone is 400 mesh, and the added medical stone accounts for 1% of the weight of the wine grains. Mix evenly, put into the tank for fermentation. The traditional liquor brewing process is adopted, and the cellar is released after a 60-day fermentation period. The process flow chart is shown in the attached drawing. The obtained original wine has an increase of about 10% in the output of high-grade wine and wine yield; the content of beneficial bacteria in the pit mud increases, and the growth of the bacterial group is active; the produced original wine is clear and transparent, with a strong grain aroma, mellow taste, Sweet and supple. The difference between the existing method and the processing method of this embodiment is that the existing method does not add medical stones to process the wine grains during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com