Underground dark mining drilling well gas extraction method

A technology of gas drainage and mining, which is applied in the fields of gas discharge, mining equipment, and earthwork drilling, etc., and can solve the limitation of popularization and application of ground drilling gas drainage methods, the great influence of rock formation stability and surface topography, and the restriction of pressure relief Gas control effect and other issues, to achieve good drainage effect, large amount of gas drainage, easy drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

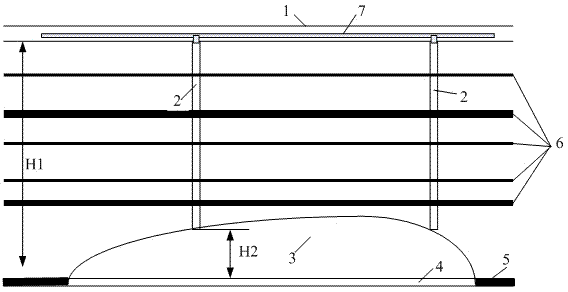

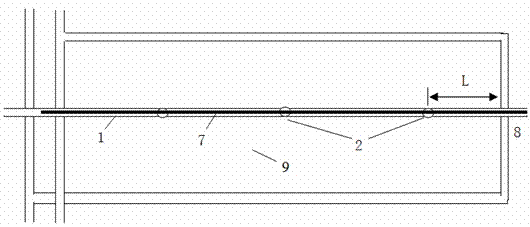

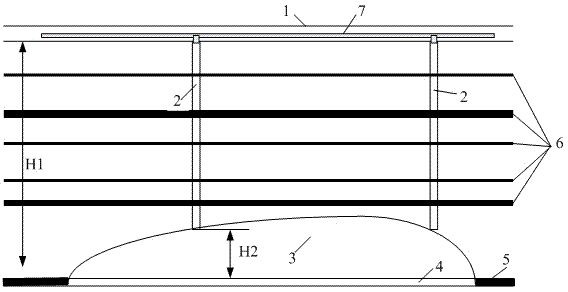

[0017] Such as figure 1 As shown, the gas drainage method for underground mining and drilling of the present invention: determine the first mining coal seam 5 in the coal seam group according to the geological exploration information, and be 150m in the upper group coal seam goaf with the vertical distance H1 of the first mining coal seam 5 Select a rock layer that is less deformed and more stable due to the impact of mining from the hard rock layer below or above all unmined coal seams, and construct a gas drainage roadway 1 in this rock layer, and construct it along the middle of the first mining face 9. The cross-sectional area of gas drainage roadway 1 is 5-8m 2 ; In the gas drainage roadway 1, a concealed mining moving well 2 with a diameter of 300mm is constructed every 100-150m. The distance from H2 is 10m; the distance L between the underground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com