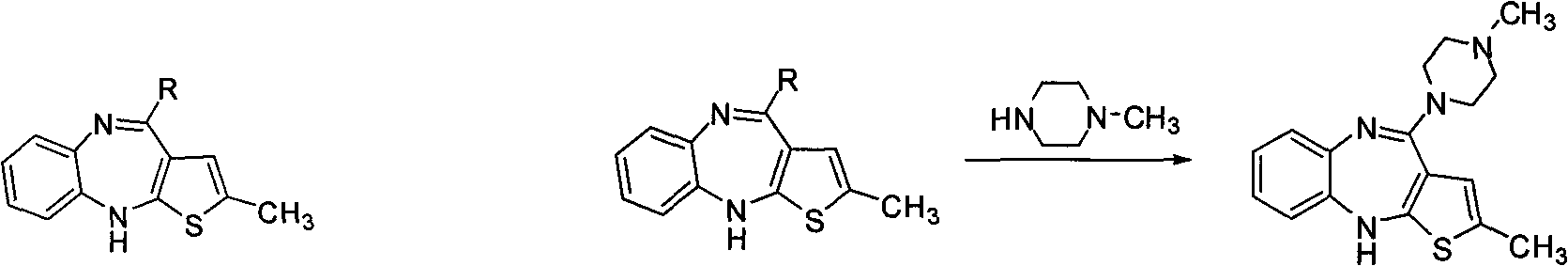

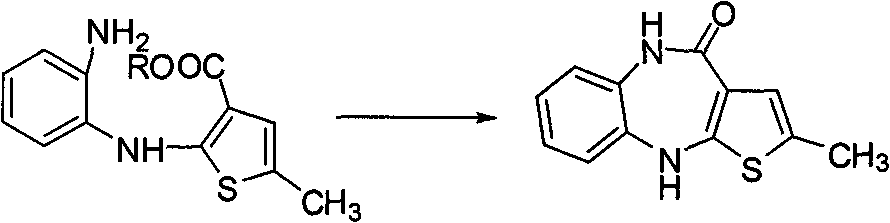

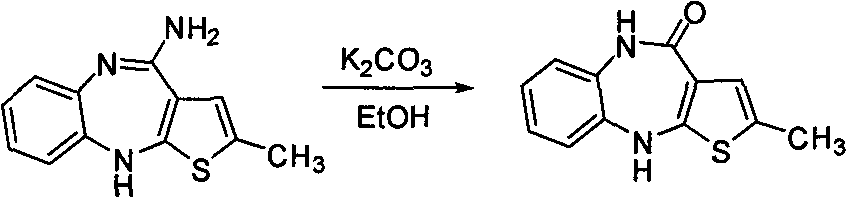

Preparation method of antipsychotic drug olanzapine

A technology of antipsychotics and olanzapine, applied in the direction of organic chemistry, can solve the problems of high production cycle and cost, complicated process and post-processing, and high requirements for reaction conditions, and achieve cost reduction, high product yield, and post-processing Easy to handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Malononitrile (66.1g, 1.0mol), sulfur (32.0g, 1.0mol), triethylamine (10.1g, 0.1mol) and DMF (200mL) were placed in a 1000mL reaction flask, and propionaldehyde ( 61.0g, 1.05mol) and DMF (100mL) solution, dripping over 1h. After dropping, keep warm at 40-50°C for 3 hours. The reaction solution was poured into ice water (1000 mL), stirred for 30 min, filtered and washed with water. The obtained crude product was recrystallized by ethanol-water system to obtain pure compound 9 (60.7 g, 0.439 mol), with a yield of 43.9%.

Embodiment 2

[0068] Malononitrile (66.1g, 1.0mol), sulfur (32.0g, 1.0mol), triethylamine (10.1g, 0.1mol) and THF (200mL) were placed in a 1000mL reaction flask, and propionaldehyde ( 61.0g, 1.05mol) and THF (100mL) solution, dripping over 1h. After dropping, keep warm at 40-50°C for 3 hours. The reaction solution was poured into ice water (1000 mL), stirred for 30 min, filtered and washed with water. The obtained crude product was recrystallized from ethanol-water system to obtain pure compound 9 (55.4 g, 0.401 mol), with a yield of 40.1%.

Embodiment 3

[0070] Malononitrile (66.1g, 1.0mol), sulfur (32.0g, 1.0mol), triethylamine (10.1g, 0.1mol) and DMSO (200mL) were placed in a 1000mL reaction flask, and propionaldehyde ( 61.0g, 1.05mol) and DMSO (100mL) solution, dripping over 1h. After dropping, keep warm at 40-50°C for 3 hours. The reaction solution was poured into ice water (1000 mL), stirred for 30 min, filtered and washed with water. The obtained crude product was recrystallized from ethanol-water system to obtain pure compound 9 (52.0 g, 0.376 mol), with a yield of 37.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com