Multifunctional electric self-cleaning teaching blackboard

A self-wiping, multi-functional technology, applied in the field of teaching blackboards, can solve the problems of the limited length and size of the back and forth stroke of the wiper brush, the limited area of the comprehensive wipe board, and the difficulty in installation and maintenance, so as to be beneficial to human health and installation. The effect of easy maintenance and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

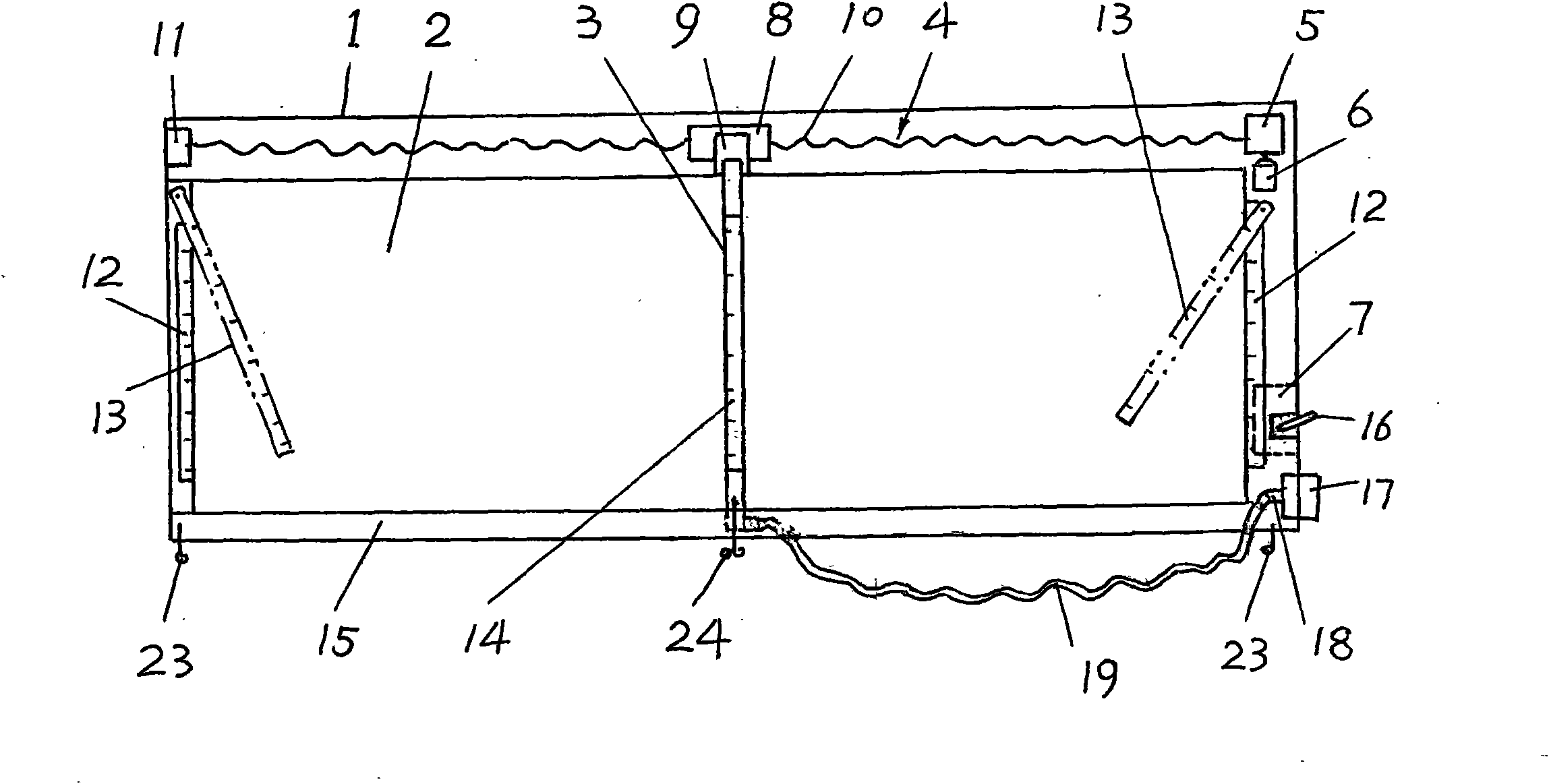

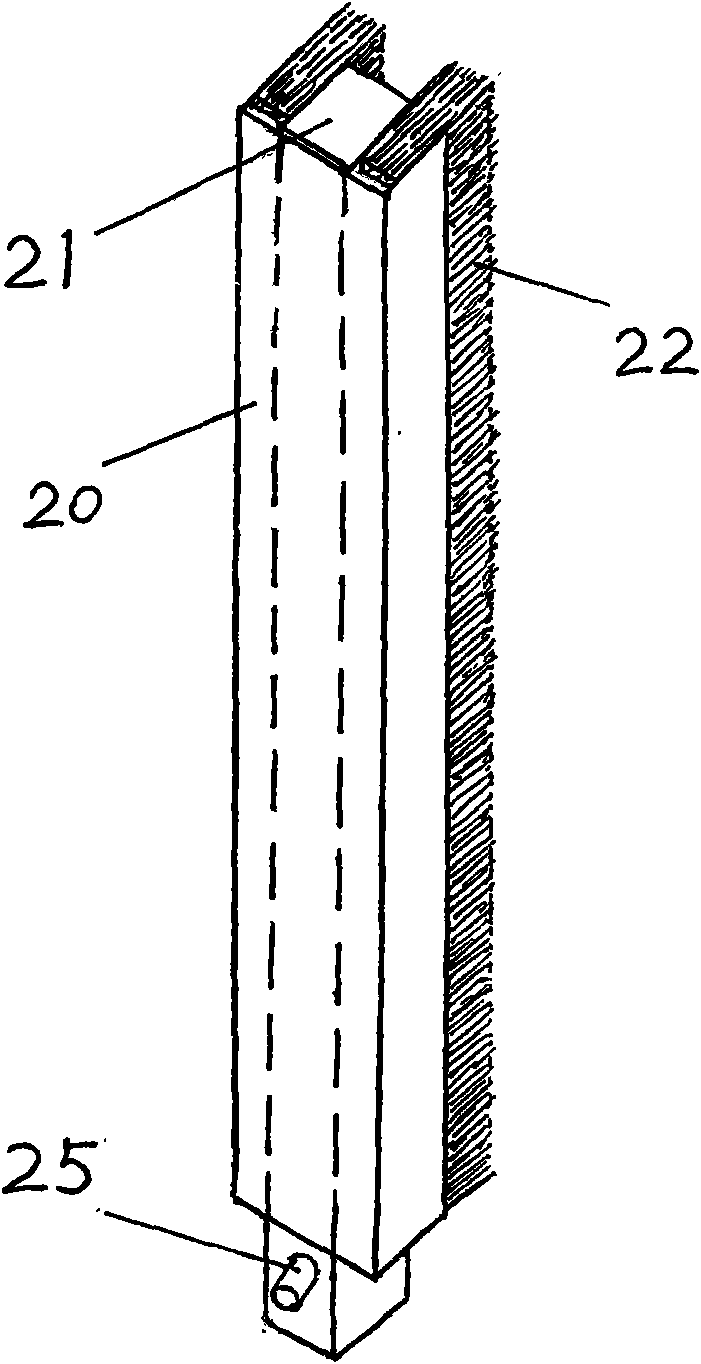

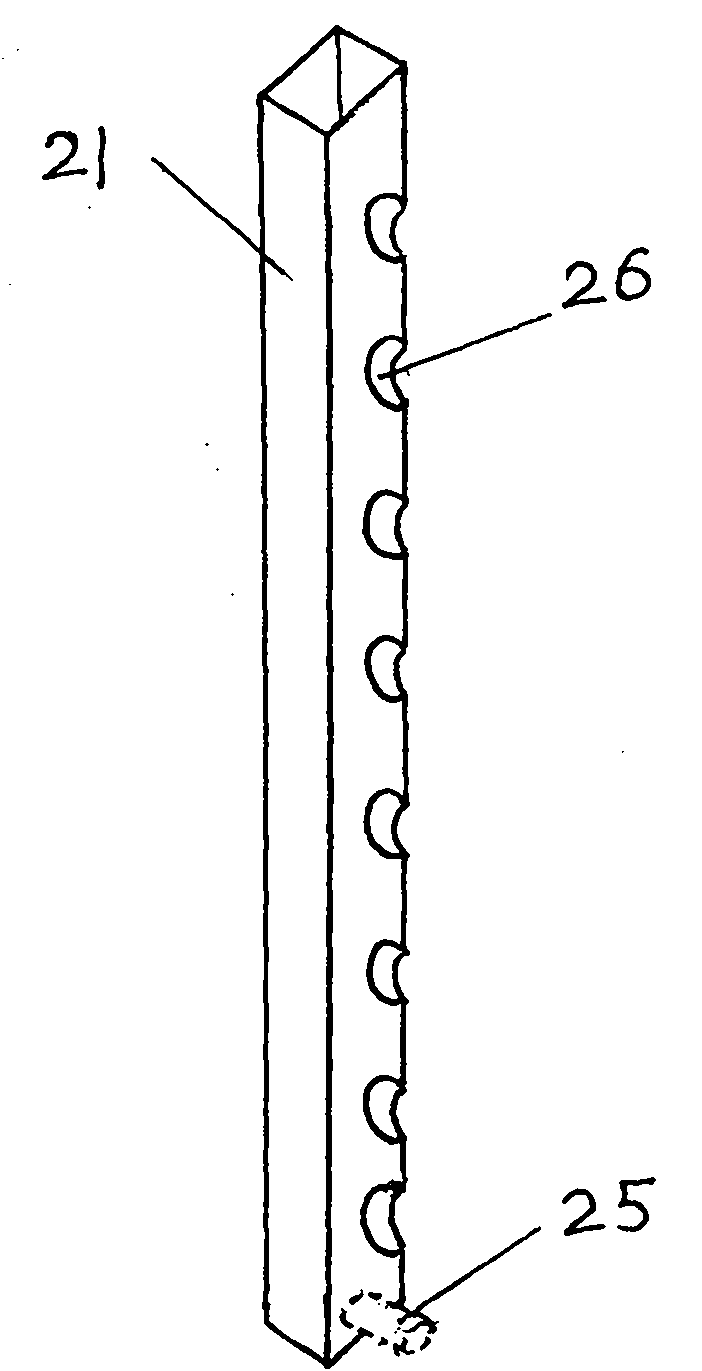

[0021]With reference to the accompanying drawings, it can be seen that the specific parts of this multifunctional electric self-erasing type teaching blackboard of the utility model of the present invention include: 1~outer frame (also known as frame), 2~blackboard panel, 3~strip blackboard brush, 4~as The screw nut moving mechanism of the driving mechanism (also known as the screw nut dragging mechanism), 5 ~ gear speed change mechanism, 6 ~ bidirectional motor with forward and reverse rotation (such as bidirectional reversible motor or adjustable speed bidirectional motor), 7 ~ electric motor Controller (electric control board), 8~nut as the driving connection block, 9~brush body mounting frame, 10~screw rod, 11~screw rod mounting part (bearing part), 12~scale installed on both sides of the outer frame (or long ruler), 13~the swingable scale ruler (long ruler) that is installed on the both sides of outer frame, 14~the scale ruler (or long ruler) that is installed on the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com