Method for synthesizing molecular sieve membrane

A molecular sieve and synthetic liquid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficulty in completely eliminating pore defects, reducing the separation performance of synthesized membranes, and inability to completely eliminate pore defects, etc. Low cost, favorable for large-scale production, uniform seed layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

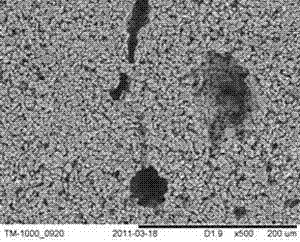

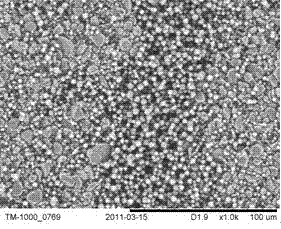

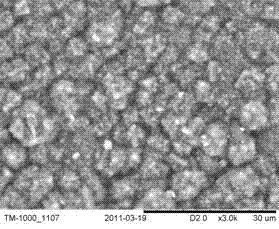

Image

Examples

Embodiment 1

[0029] Step A. Configure seed slurry

[0030] Weigh 3.18 grams of sodium metaaluminate and dissolve it in 12.21 grams of deionized water, then weigh 9.38 grams of sodium metasilicate nonahydrate and 0.17 grams of sodium hydroxide and dissolve it in 18.1 grams of deionized water, and add the sodium metaaluminate aqueous solution dropwise to In the sodium metasilicate solution, fully stir the resulting mixed solution, the mixed solution is stirred and aged at room temperature for 1 day and then used as the sol of the seed crystal slurry for subsequent use, and its composition is Na 2 O: A1 2 o 3 : SiO 2 : H 2 O=3.4: 1: 2: 120. Take by weighing 0.5 gram of this sol and mix it with 0.78 gram of NaA molecular sieve crystals and 0.46 gram of water with a particle size of 1 μm to prepare a seed crystal slurry. The mass ratio of the seed crystal to the solid in the sol is 90:10, and the amount of water in the slurry is Quality is 50%;

[0031] Step B. Pre-coat the seed layer

...

Embodiment 2

[0036] Step A. Configure seed slurry

[0037] Weigh 3.18 grams of sodium metaaluminate and dissolve it in 8.25 grams of deionized water, then weigh 2.65 grams of sodium silicate and 0.33 grams of sodium hydroxide and dissolve it in 8.93 grams of deionized water, and add the sodium metaaluminate aqueous solution dropwise to the sodium silicate In the solution, the resulting mixed solution was fully stirred, and the mixed solution was stirred and aged at room temperature for 2 days and then used as the sol of the seed crystal slurry for subsequent use, and its composition was Na 2 O: A1 2 o 3 : SiO 2 : H 2 O=2: 1: 1.5: 60. Take by weighing 0.62 grams of this sol and mix it with 0.6 grams of NaA molecular sieve crystals with a particle size of 5um and 0.65 grams of water to prepare seed crystal slurry. The mass ratio of seed crystals to solids in the sol is 80:20, and the amount of water in the slurry is Quality is 60%;

[0038] Step B. Pre-Apply Seed Layer

[0039] With e...

Embodiment 3

[0043] Step A. Configure seed slurry

[0044] Weigh 3.18 grams of sodium metaaluminate and dissolve it in 19.8 grams of deionized water, then weigh 14.08 grams of sodium metasilicate nonahydrate and 0.99 grams of sodium hydroxide and dissolve it in 31.6 grams of deionized water, and add the sodium metaaluminate aqueous solution dropwise to In the sodium metasilicate solution, fully stir the resulting mixed solution, the mixed solution is stirred and aged at room temperature for 2 days and then used as the sol of the seed crystal slurry for subsequent use, and its composition is Na 2 O: A1 2 o 3 : SiO 2 : H 2 O=5: 1: 3: 200. Weigh 0.5 grams of the sol and mix it with 7.37 grams of NaA molecular sieve crystals with a particle size of 0.1um and 2.7 grams of water to prepare a seed crystal slurry. The mass ratio of the seed crystal to the solid in the sol is 99:1, and the water in the slurry The mass of 30%;

[0045] Step B. Pre-Apply Seed Layer

[0046] Same as Example 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com