Wiring board and method for manufacturing wiring board

A manufacturing method and wiring board technology, which is applied in the fields of printed circuit manufacturing, multilayer circuit manufacturing, semiconductor/solid-state device manufacturing, etc., can solve problems such as conductor circuit short circuit and wiring board reliability reduction, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

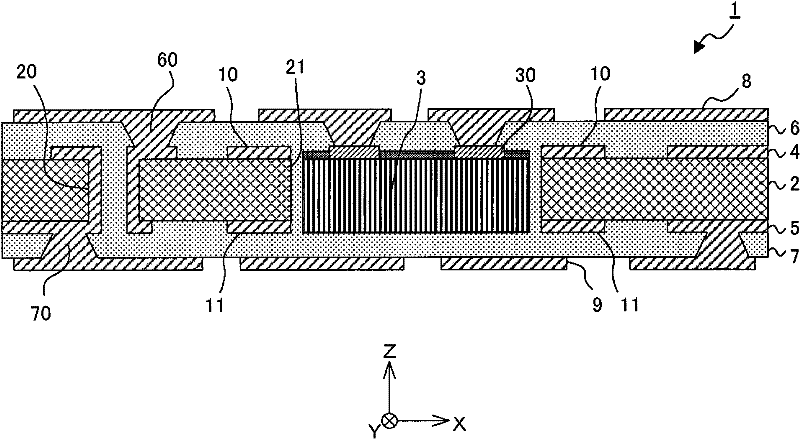

[0058] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In addition, in the description, a coordinate system composed of mutually orthogonal X-axis, Y-axis and Z-axis is used.

[0059] figure 1It is a schematic cross-sectional view of electronic component built-in wiring board 1 according to this embodiment. The wiring board 1 with built-in electronic components includes: a substrate 2; electronic components 3 accommodated in the substrate 2; conductor patterns 4, 5 and interlayer insulating layers 6, 7 formed on the upper and lower surfaces of the substrate 2; Conductor patterns 8, 9 on the surfaces of layers 6, 7; Conductor pattern 10 formed on the upper surface (+Z side surface) of the substrate 2; Conductor pattern 11 formed on the lower surface (-Z side surface) of the substrate 2 .

[0060] The substrate 2 is made by impregnating a reinforcing material (substrate) such as glass fiber cloth (glass cloth), glass non-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com