Single-shaft tensile overall true stress-true strain curve testing technique

A technology of uniaxial tension and true stress, which is applied in the direction of applying stable tension/compression to test the strength of materials, and can solve the problems of failure to truly reflect the characteristics of load and displacement deformation, and unreasonableness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

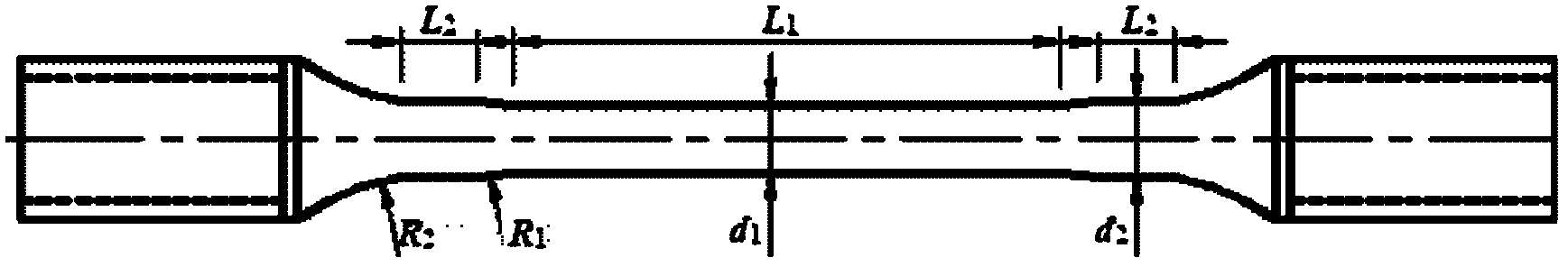

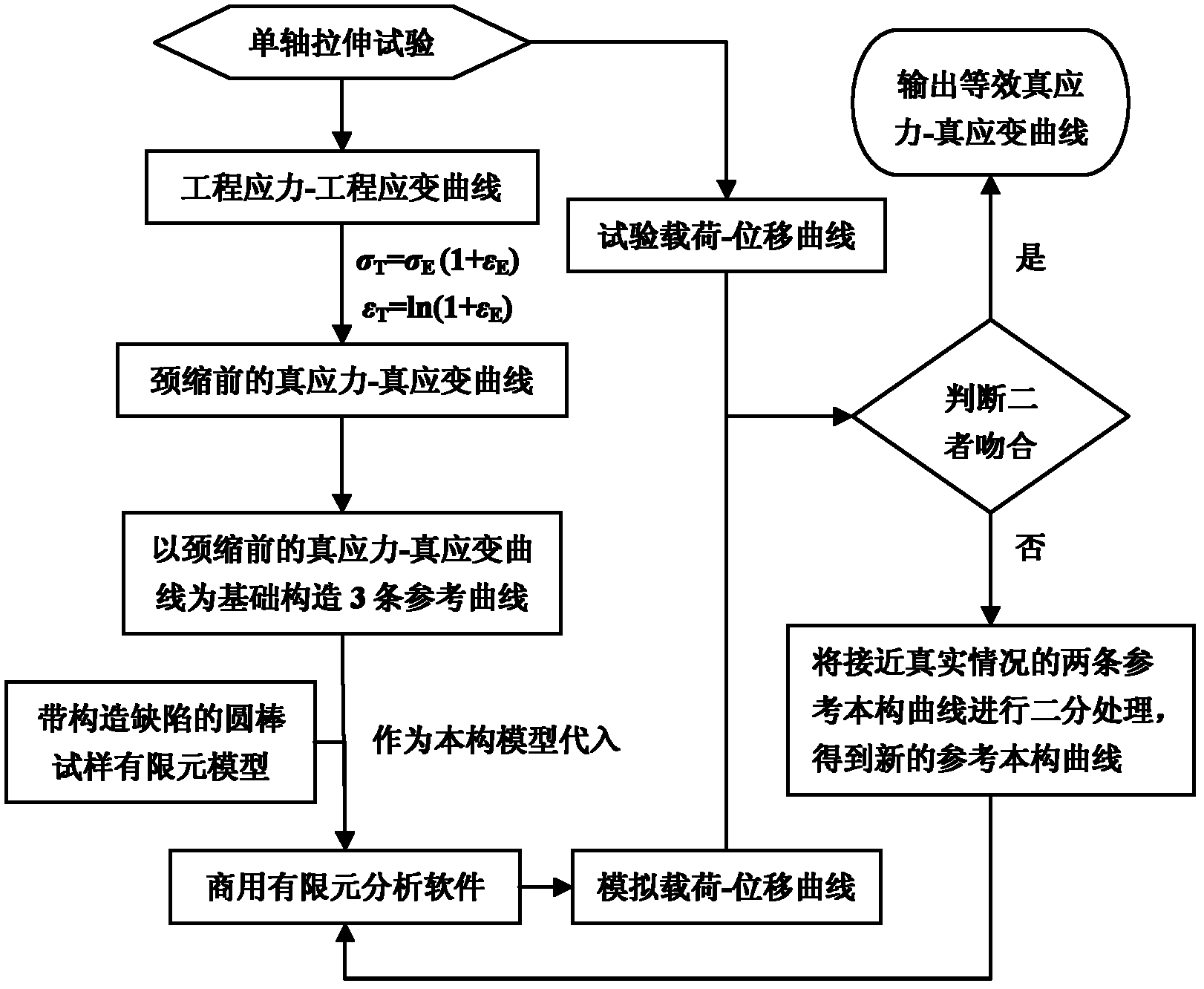

[0035] Taking 316L stainless steel as an example to further illustrate the specific implementation method of the technical solution of the present invention. The stress-engineering strain curve and load-displacement curve are converted from the engineering stress-engineering strain data obtained by the uniaxial tensile test of the round bar sample. The finite element simulation is carried out with ANSYS11.0, and the regular SLR camera that can take pictures at regular intervals is used to continuously take pictures of the deformation laws of the sample during stretching, and the images taken are processed mathematically using Getdata software. The necking occurs near the middle section of the sample, Figure 4 is the comparison result of the test load-displacement curve and the simulated load-displacement curve, Figure 5 is the optical measurement and simulation results of the minimum section diameter-displacement curve of the necked root of the sample, Figure 6 is the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com