Non-contact vehicle gear sensor

A kind of automobile gear position and non-contact technology, which is applied in the field of sensors, can solve the problems of easy failure, poor contact, easy wear, etc., and achieve the effect of accurate and stable output signal, prolonging working life, improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

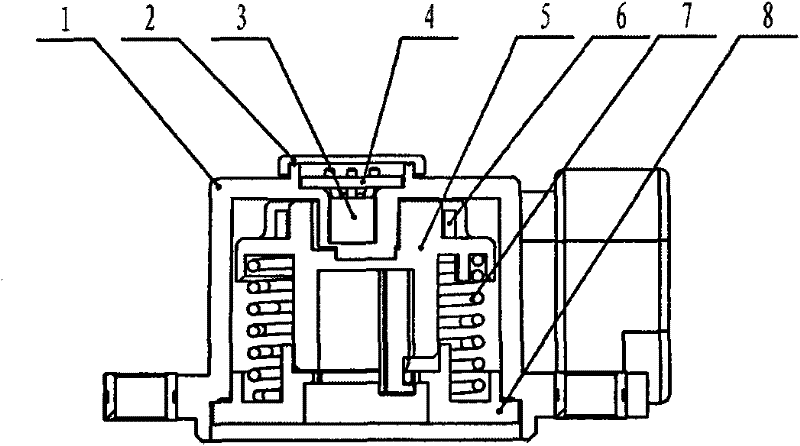

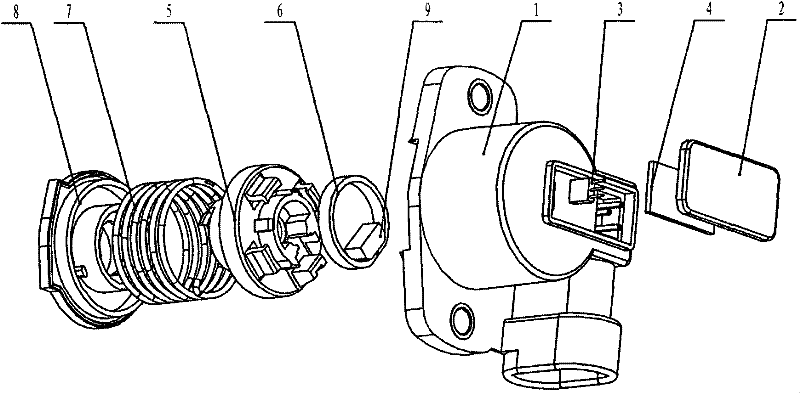

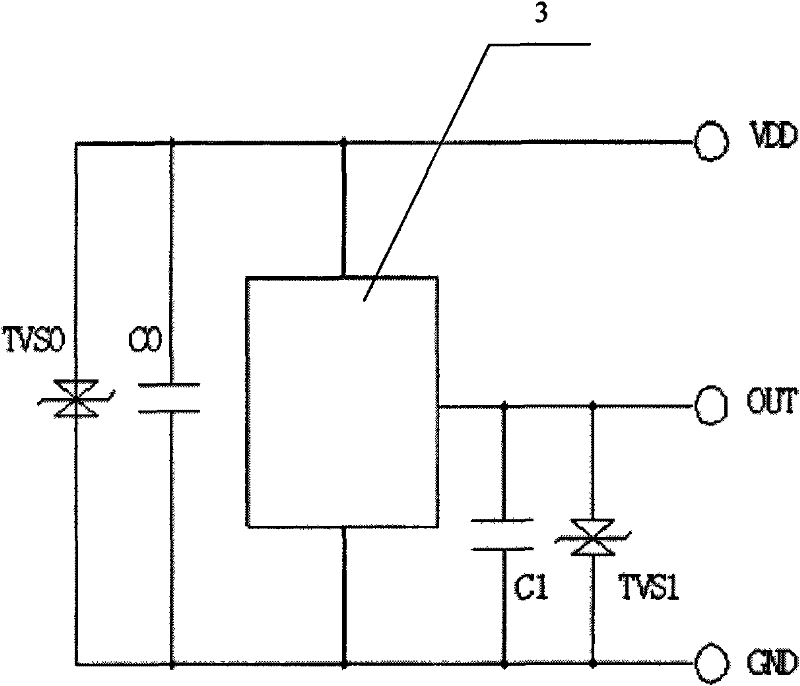

[0021] see figure 1 and figure 2 , the non-contact automobile gear position sensor includes a cylindrical casing 1, an upper cover plate 2 is arranged at the axial top of the casing 1, and a lower cover plate 8 is arranged at the axial bottom; the inner side of the upper cover plate 2 is provided with a circuit board 4. The circuit board 4 is connected to the Hall chip 3, the Hall chip 3 is located in the housing 1, the outer side of the Hall chip 3 is provided with a hollow rotating shaft 5, and the upper part of the hollow rotating shaft 5 corresponding to the Hall chip 3 is sleeved. The magnetic conducting ring 6, the inner side wall of the magnetic conducting ring 6 is connected with the magnet 9, and the magnet 9 corresponds to the Hall chip 3; the outer middle of the hollow shaft 5 is radially provided with a positioning ring, and the upper surface of the positioning ring is evenly provided with three hooks , the hook catches the magnetic conductive ring 6 sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com