Braking device of wind power generation yaw bearing

A braking device and yaw bearing technology, applied in the control of wind turbines, wind turbines, wind turbine components, etc., can solve the problems of the yaw system not working properly, the brake structure being complex, and the easy retention of lubricating oil, etc. Eliminate asymmetry, simple structure, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

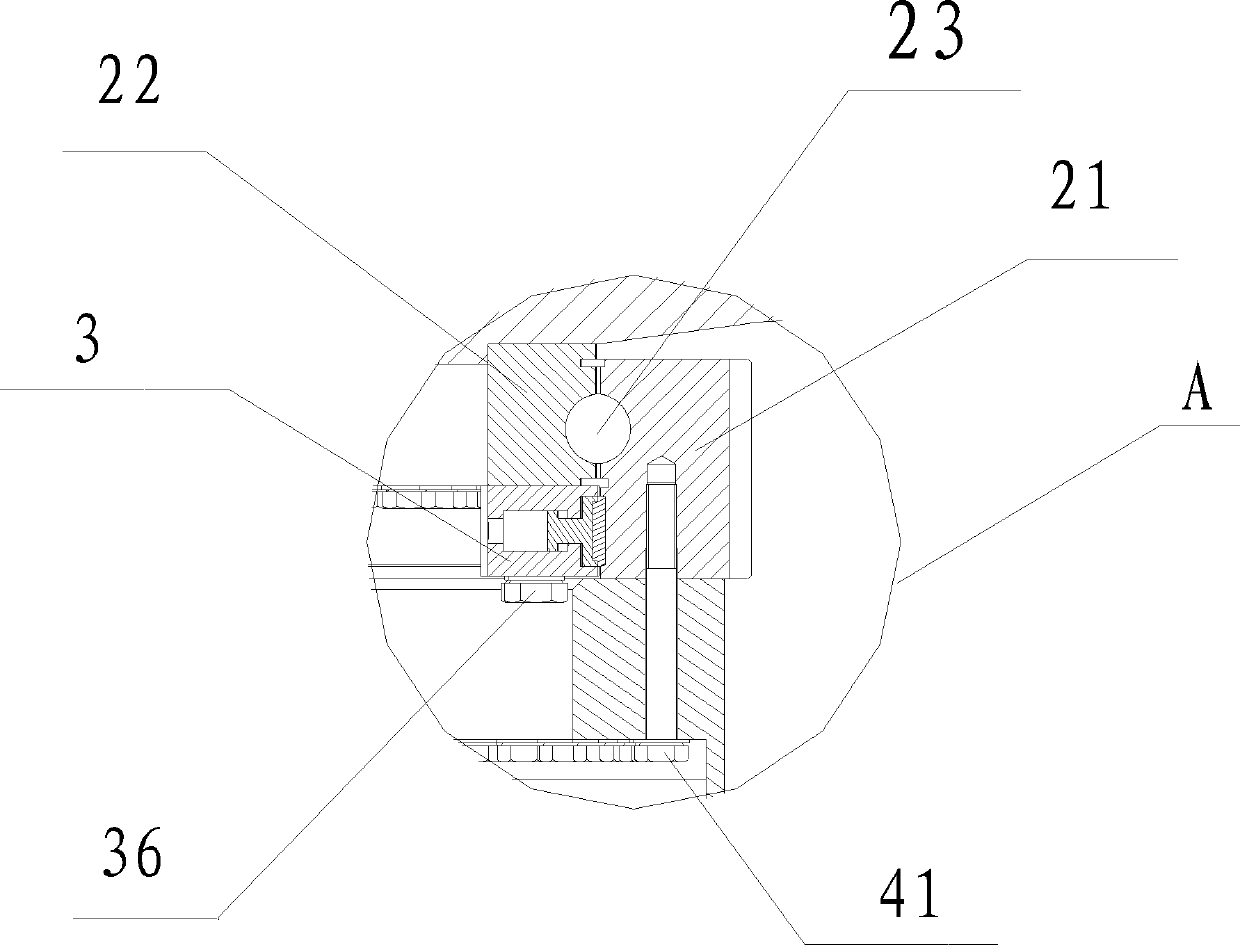

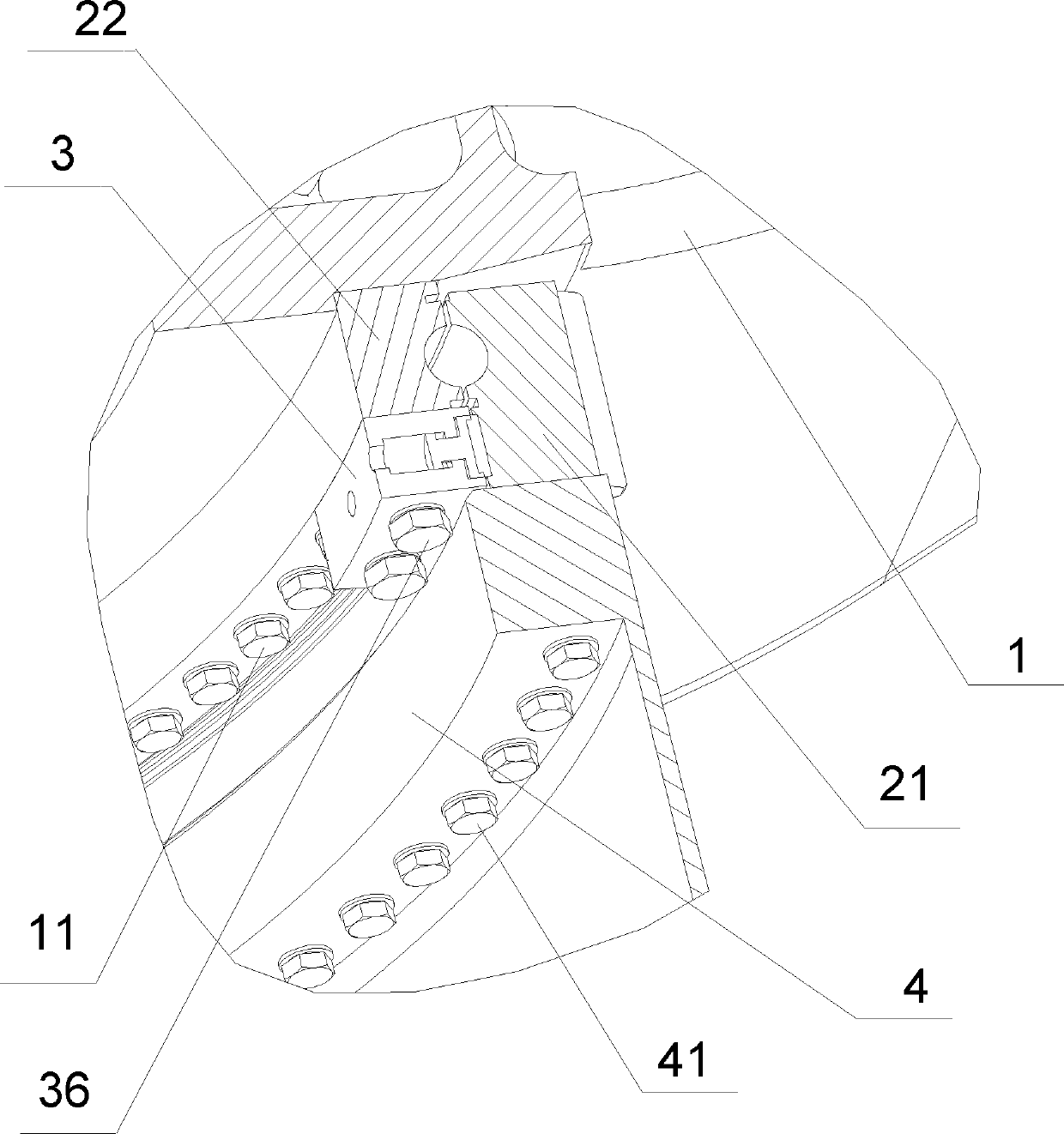

[0037] Such as figure 1 figure 2 image 3 Figure 4 Figure 11 Figure 12 As shown, scheme 1: a braking device for a wind power yaw bearing, which has a yaw slewing bearing, the yaw slewing bearing is composed of an outer bearing ring 21 and an inner bearing ring 22, and the outer circumference of the outer bearing ring 21 has an external gear , the upper part of the outer bearing ring 21 is connected with the inner bearing ring 22 through balls 23, and the inner surface of the lower part of the outer bearing ring 21 has a bearing braking surface concave in the ring direction, and the bearing braking surface is the inner surface of the outer bearing ring. The braking surface of the inner ring, the braking surface 24 of the inner ring is a trapezoidal groove surface.

[0038] The lower end surface of the inner bearing ring 22 is equipped with a plurality of sector brakes 3. The sector brakes 3 are composed of a brake base 31, a brake bracket 32 and a brake pad 33. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com