Vortex cleaning drill pipe

A drill pipe and vortex technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., to achieve the effect of improving rock-carrying efficiency, enhancing rock-carrying ability, and improving flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

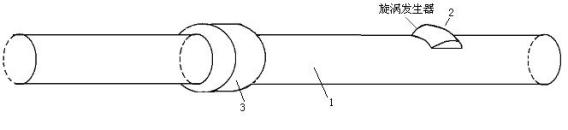

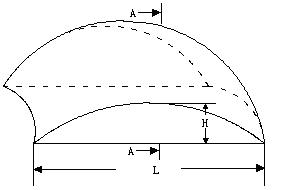

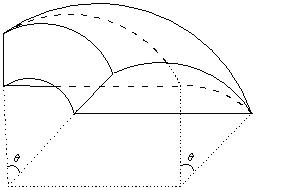

[0024] Example 1: see Image 6 , This vortex cleaning drill pipe is a drill pipe body (1) with a set of symmetrical vortex generators 2, see figure 2 with image 3 , The vortex generator 2 is a bar raised on the surface of the drill pipe body (1), the height of the bar Range is 1~19mm, length The range is 20cm~50cm, the central angle corresponding to the width of the contact with the drill pipe surface At 10~60°, the center angle corresponding to the end face width is 10~82°, and there is a smooth transition between the length direction and the drill pipe surface. See the corresponding annular space annulus structure Figure 7 , See the corresponding flow field vortex diagram Figure 8 .

Embodiment 2

[0025] Example 2: see Picture 9 , This vortex cleaning drill pipe is a drill pipe body (1) with two sets of symmetrical vortex generators (2), the vortex generators (2) are blade-shaped, and the upper and lower drill pipes are connected by a drill pipe joint (3). The corresponding annular space gas streamline diagram is shown in Picture 10 .

[0026] The principle is as follows:

[0027] The invention uses the vortex generator to not only generate vortices, but also effectively increase the tangential velocity of the gas in the annular space. Therefore, the vortex cleaning drill pipe can effectively improve the rock-carrying effect of the annular space in the horizontal well section and reduce the possibility of formation of cuttings beds. . figure 2 The specific structure of the vortex generator is given. figure 1 It is a structure diagram of a vortex cleaning drill pipe with a single vortex generator. Figure 5 It is a vortex diagram in a section near a single vortex generato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com