Construction method of deformable template of variable cross-section high pier

A construction method and high pier technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of large formwork, machine tool rental and access fees increasing unit project construction cost, difficult construction, high construction cost, etc., to achieve technical Strong economic advantages, saving tower cranes and large formwork, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

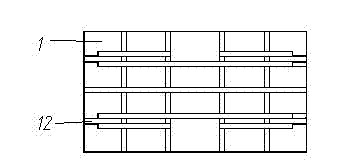

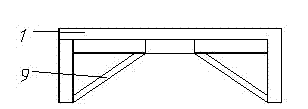

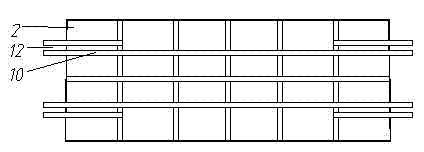

[0035] The construction method of variable formwork for variable cross-section high bridge pier of the present invention includes the installation of the external formwork combination of each pouring section. The external formwork combination of each pouring section is fixed and stacked together by several layers of formwork from bottom to top, see Figure 7 . Each layer of formwork is surrounded by two horizontal formwork 1 and two vertical formwork 2, the transverse formwork 1 is rectangular and its width is the width of the pier, see figure 1 ; The longitudinal formwork 2 is an isosceles trapezoid and equal to the horizontal formwork 1, see image 3 with Figure 4 . The horizontal template and the vertical template correspond to the horizontal and vertical of the bridge. The installation steps of the outer mold combination of each pouring section are as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com