Seed crystal lifting device for Czochralski monocrystal furnace

A single crystal furnace and straight-pull technology, which is applied in the field of seed crystal lifting devices for straight-pull single crystal furnaces, can solve the problems of high equipment height, high production cost, and low product quality rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

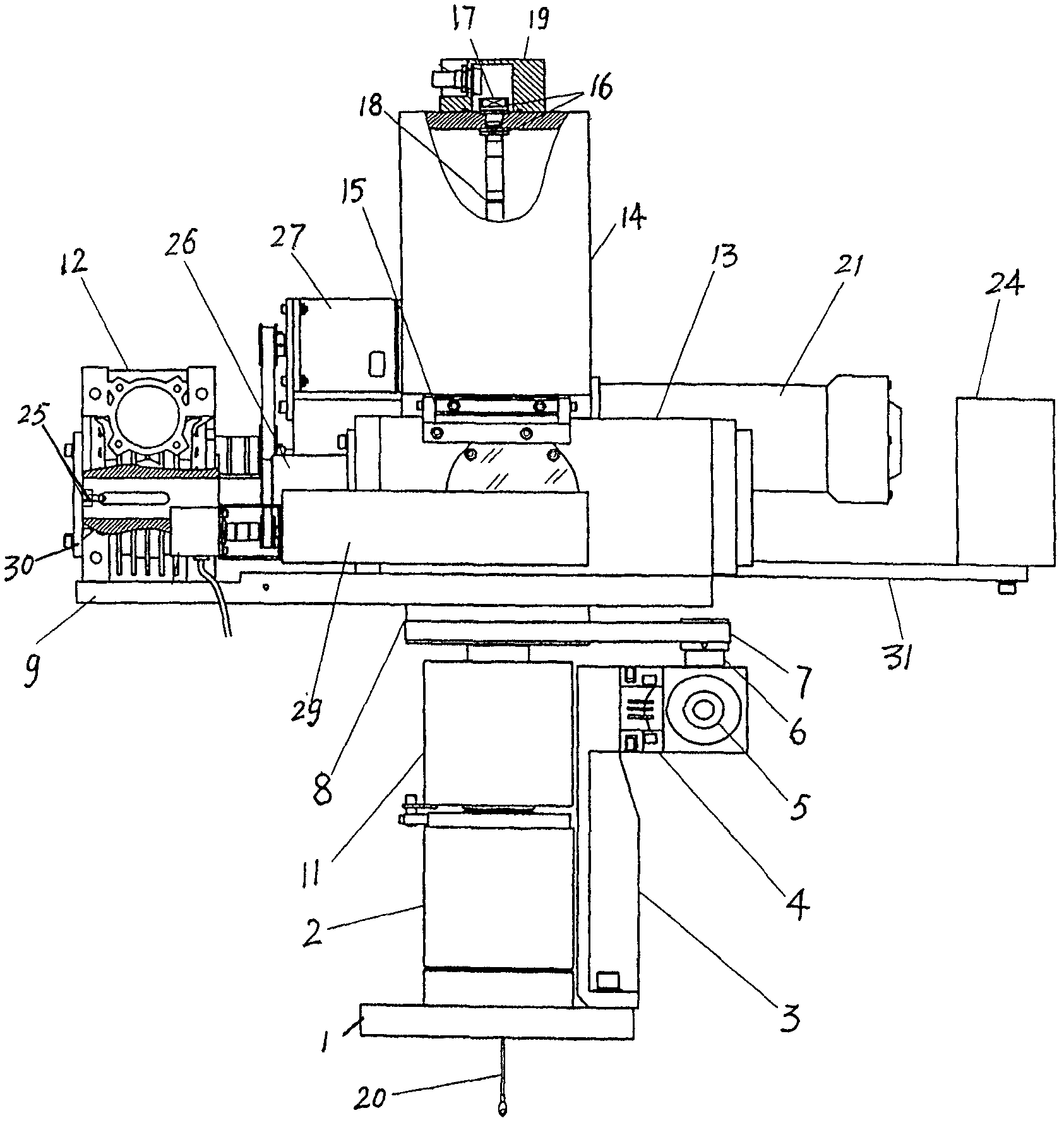

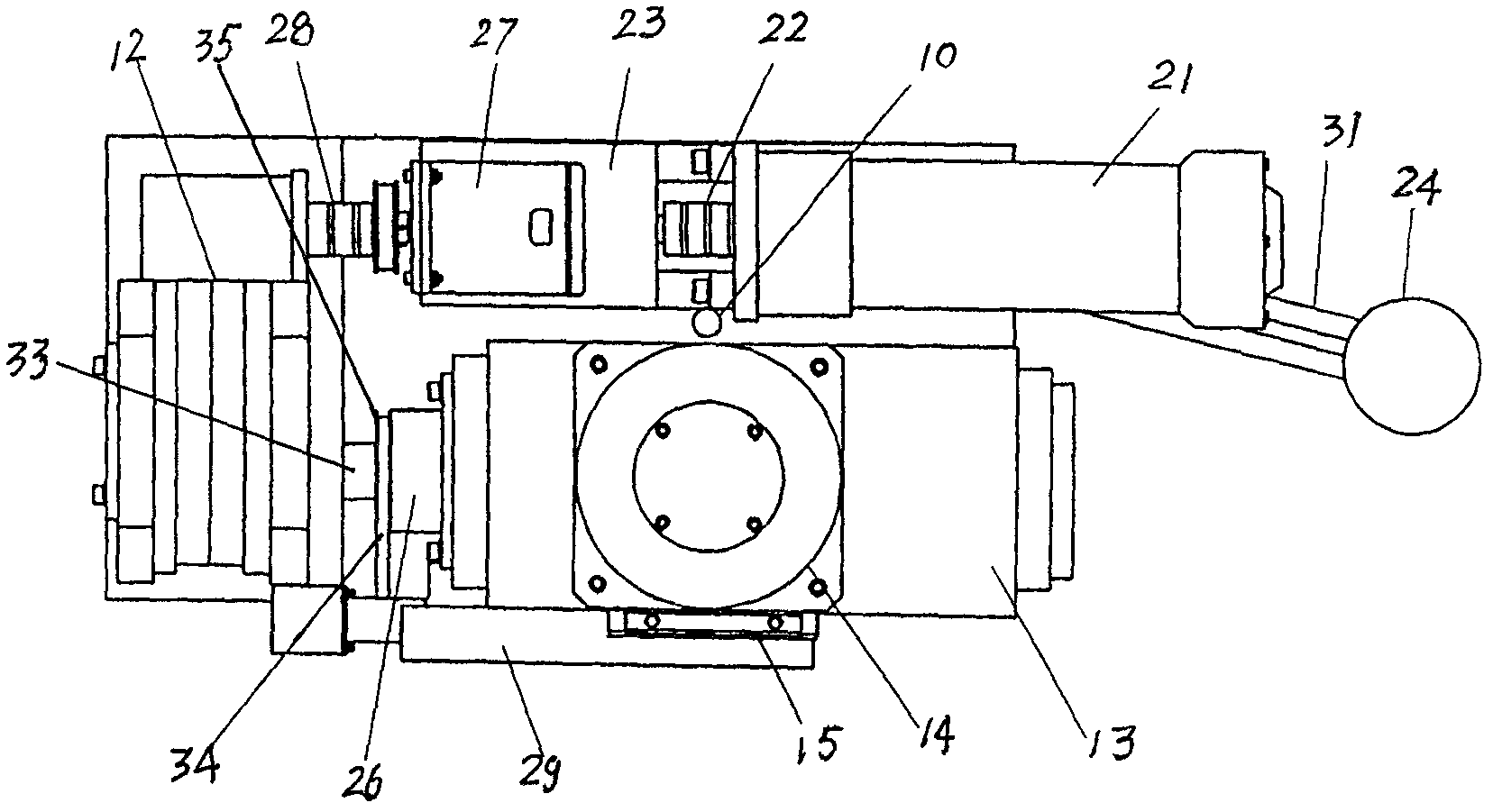

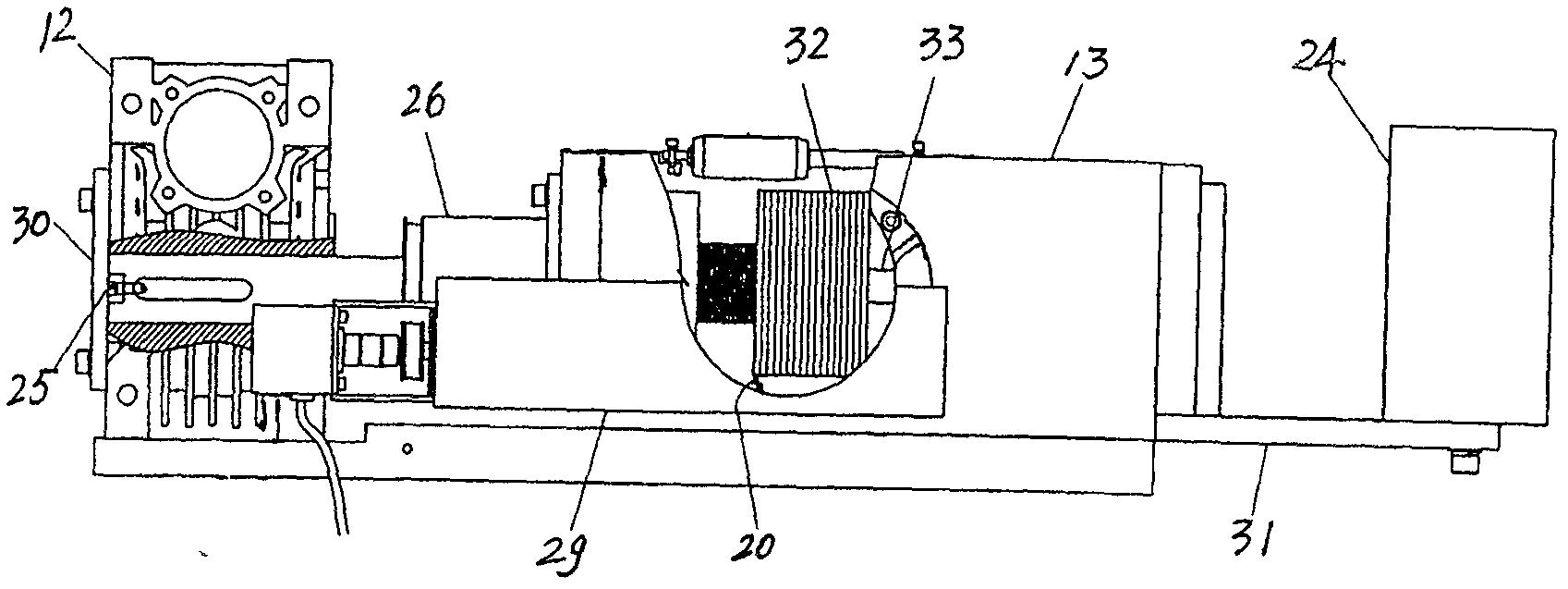

[0019] see Figure 1-Figure 3, a seed crystal lifting device for a straight-pull single crystal furnace, which consists of a top chamber assembly, a lifting chamber assembly, a two-stage transmission 12, a pullable transmission shaft 25, a clutch assembly 23, a fast motor 27, a slow motor 21, The lifting head limit mechanism 29 and the rotating assembly are formed. The top chamber assembly includes the top chamber 14, the top cover flange 19, the pin shaft 17, the plane bearing 16, and the pulley assembly 18. The lifting chamber assembly includes the lifting chamber 13, the thread pipe 32, Spline shaft 33, crystal magnetic fluid 29, rotating components include crystal bottom plate 9, weight 24, slip ring 11, crystal drive motor 5, worm gear reducer 4, crystal magnetic fluid 2, crystal magnetic The crystal-rotating magnetic fluid 2 and the crystal-rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com