Split-type wrenching-type preservation box

A fresh-keeping box and pull-type technology, which is applied to rigid containers, clamping devices, and closures, can solve problems such as large mold investment, reduced production efficiency, and difficulty in filling injection molding, and achieves simple demoulding mechanism, improved product strength, and mold Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

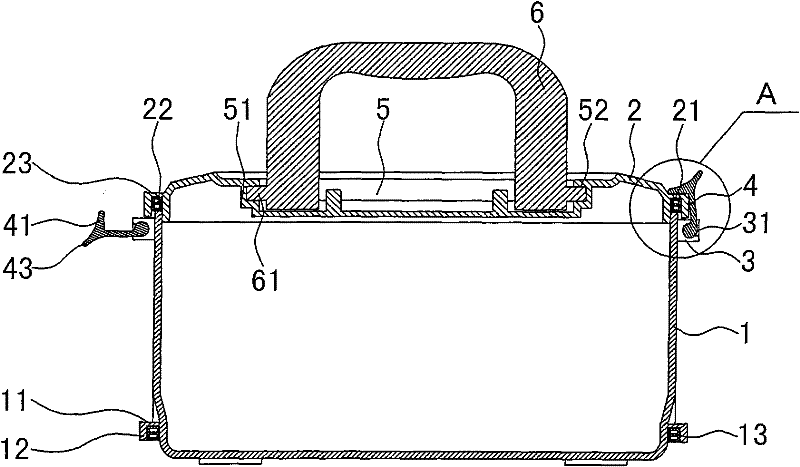

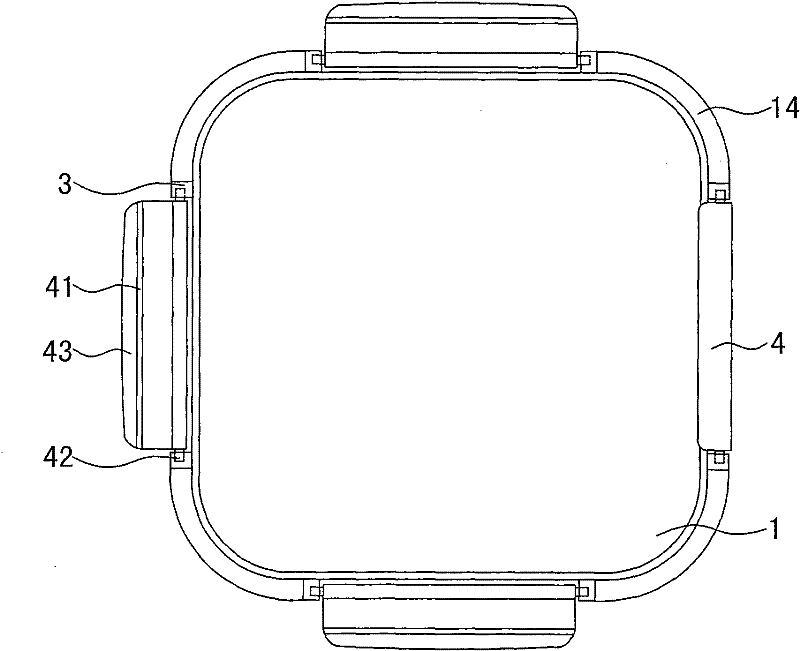

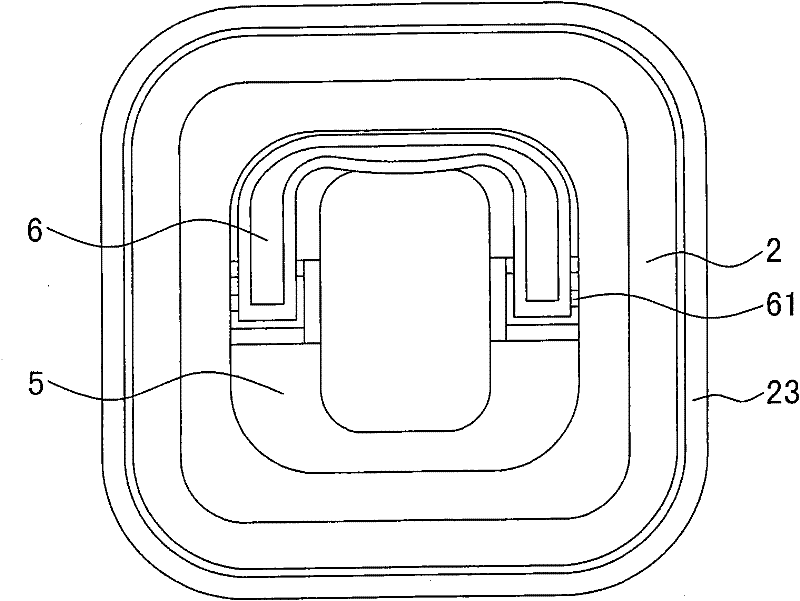

[0012] The invention relates to a split type lower-panel fresh-keeping box, such as Figure 1-Figure 5 As shown, it includes a box body 1 and a box cover 2. A fixing groove 21 is formed under the box cover 2. A sealing ring 22 is installed in the fixing groove 21, and the sealing ring is sealed with the mouth of the box body, characterized in that the box body The outer wall of 1 is provided with a connecting block 3, a connecting groove 31 is opened in the connecting block 3, and a wrench 4 is installed in the connecting groove 31. The wrench is provided with a tenon 42 at both ends, and the tenon 42 is connected to the connecting groove 31 in the connecting block 3. In the movable connection, a clip 41 is formed on the wrench, and a fixed edge 23 is formed on the box cover 2. The clip 41 of the wrench is tightly fitted with the fixed edge 23. A connecting block 3 is formed on the outer wall of the box body 1. In the actual product, each connecting block 3 is connected by a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com