Casting mould of belt pulley with groove

A casting mold and pulley technology, which is applied in the field of casting molds, can solve the problems of low durability of casting molds, increase casting costs, and poor casting quality, and achieve the effects of high casting efficiency, reduced workload and good casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

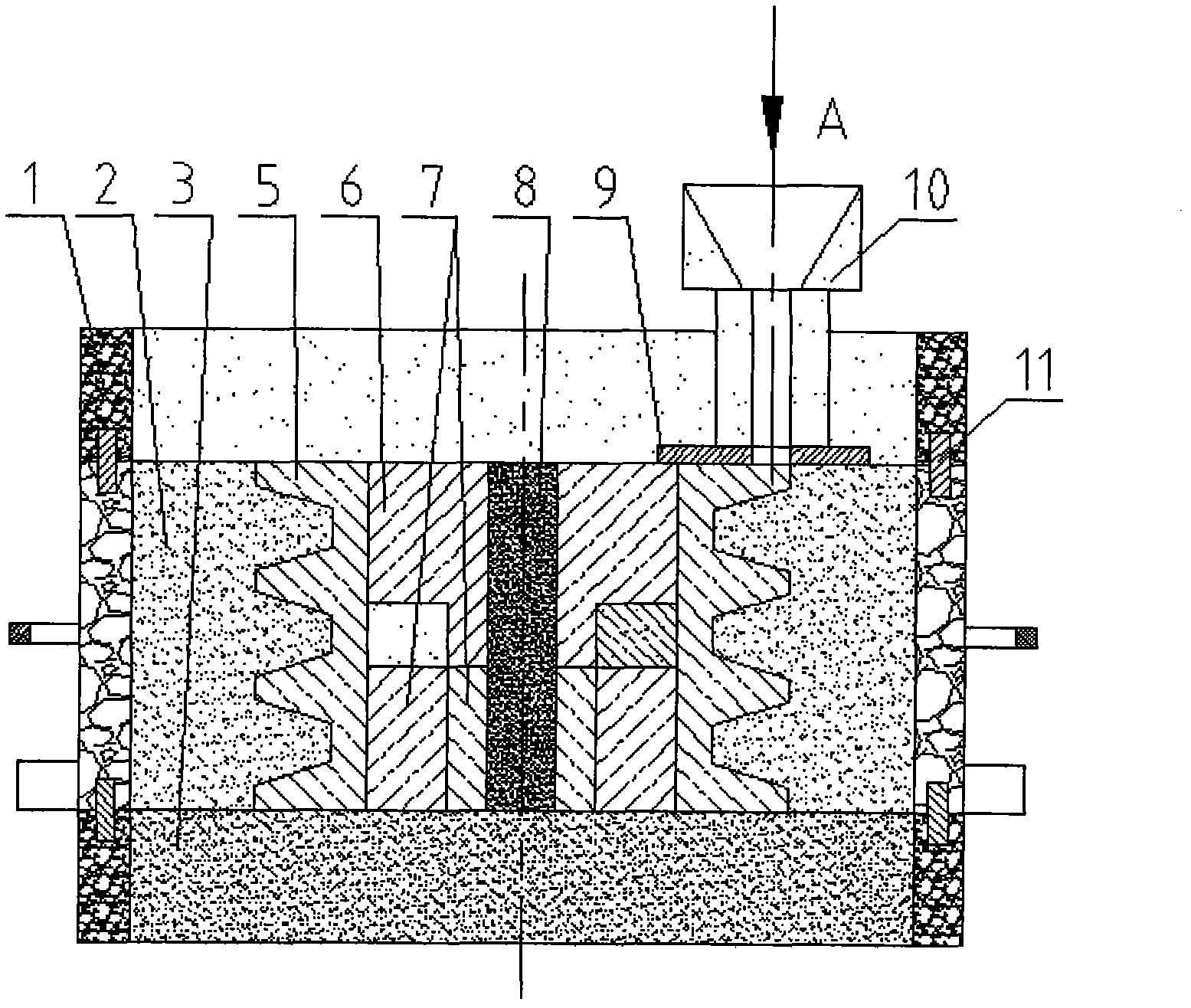

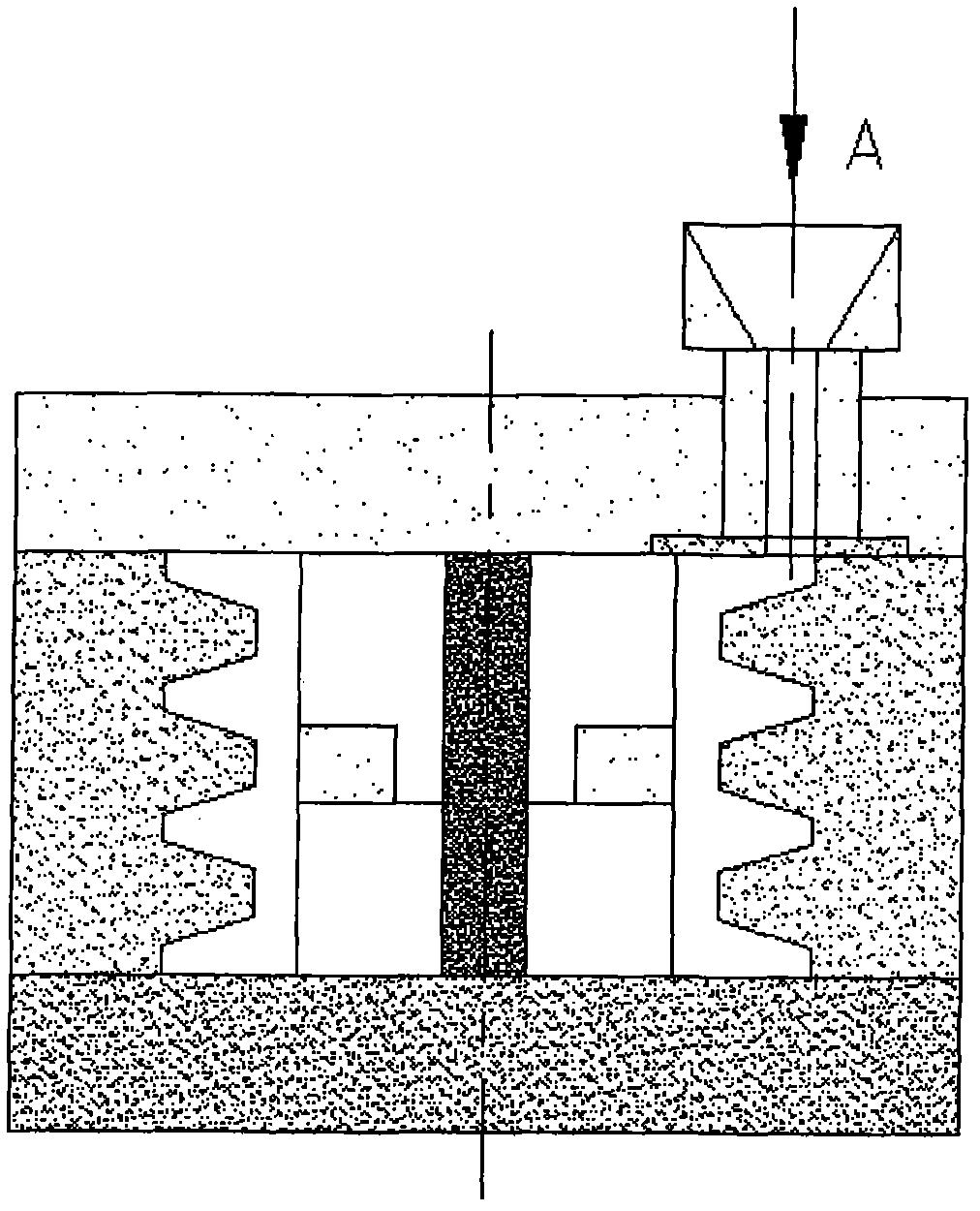

Embodiment 1

[0039]Taking the casting mold of the three-groove V-belt pulley 4 as an example, the casting process of the belt pulley with grooves of the present invention is described. The aluminum alloy is used to make mold cores respectively with reference to the profile of the three-groove V-belt pulley 4. During casting, at first the ground is supplemented with sand, dial Flat, put the lower mold 3 upside down on the sand surface, put in the lower mold core 7 and mud core 8 in turn, supplemented with sand for compaction, buckle upside down on the ground; refer to the process of the lower mold 3, lift the handle of the middle mold 2 15. Put the middle mold 2 on the sand surface, put the middle mold core 5, the auxiliary mold core 13 and the mud core 8 in turn, and the middle mold core 5 is divided into middle mold core blocks 5-1, 5-2, 5 -3, 5-4 four pieces, supplemented with sand for compaction, mold removal, and then align the pin 11 or tenon 14, put the middle mold 2 on the top of the...

Embodiment 2

[0041] Take the casting mold of double-groove V-belt pulley 19 as embodiment, illustrate the casting process of belt pulley of the present invention, adopt aluminum alloy to make mold core respectively with reference to the profile of double-groove V-belt pulley 19, at first assist sand on the ground during casting, dial Flat, put the lower mold 3 upside down on the sand surface, put in the lower mold core 7 and mud core 8 in turn, supplemented by sand for three-dimensional vibration and compaction, and buckle upside down on the ground; refer to the process of the lower mold 3, put the middle mold 2 Put it on the sand surface, put in the middle core 5, the auxiliary core 13 and the mud core 8 in turn, and the middle core 5 is divided into middle core blocks 5-1, 5-2, 5-3, 5-4 Four pieces, supplemented with sand for three-dimensional vibration and compaction, ejecting the mold, then aligning the pin 11 or tenon 14, and placing the middle mold 2 on the lower mold 3; the same proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com