Tea leaf steaming machine

A technology of degreening machine and tea, which is applied in the direction of tea treatment before extraction, etc. It can solve the problems of high CO emission concentration, low thermal efficiency of degreening machine, and destruction of atmospheric ozone layer, so as to reduce the concentration of CO and NOx, improve heating efficiency and energy utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

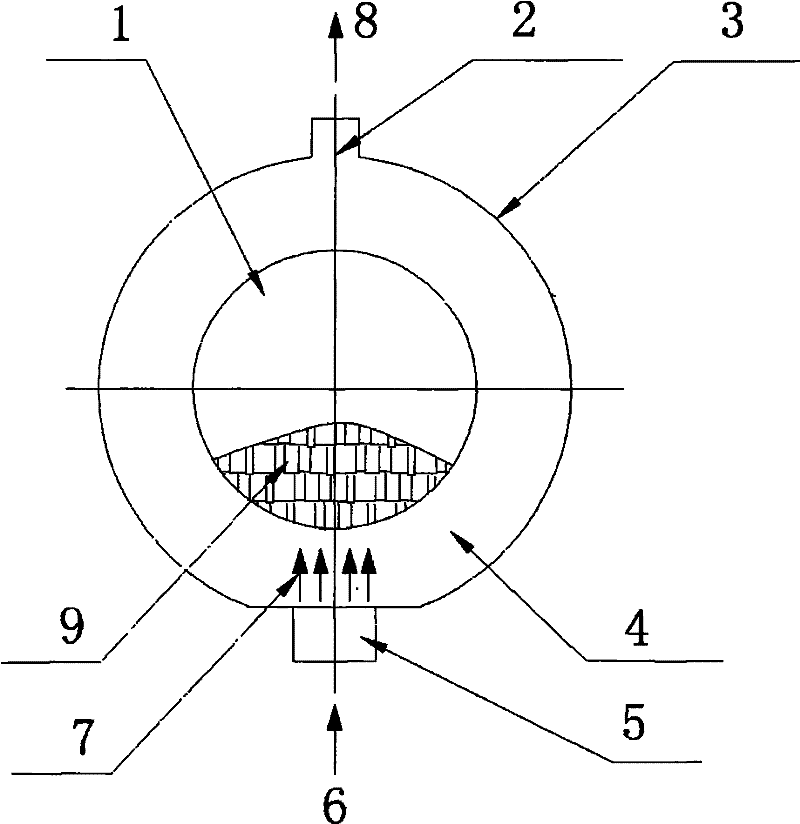

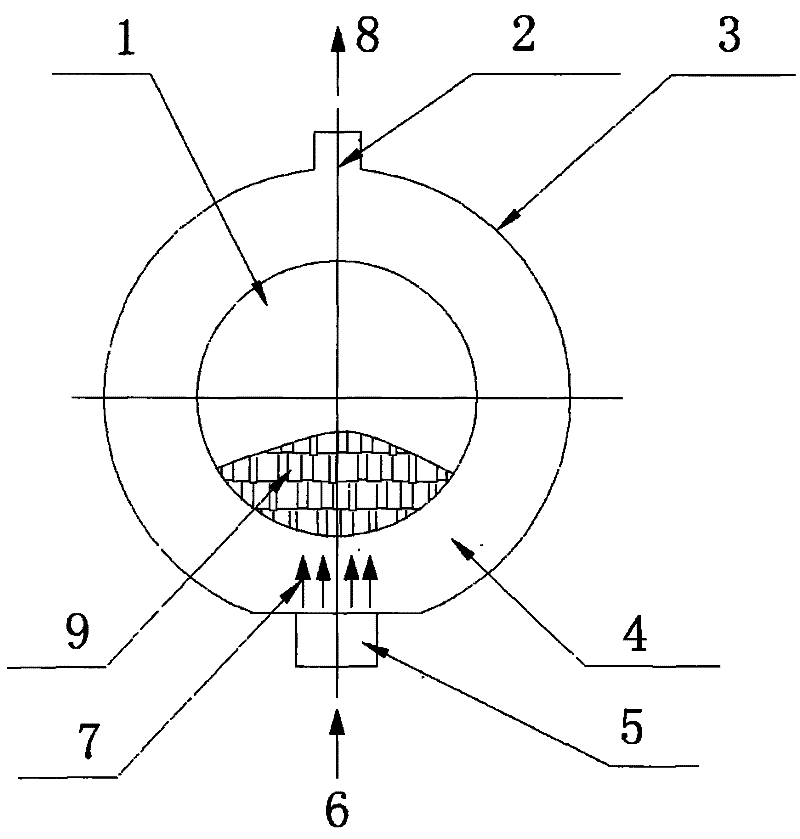

[0011] exist figure 1 Among them, the metal fiber burner (5) is installed on the housing (3), the drum (1) is a cylindrical rotating body, and is installed in the center of the housing (3), the metal fiber burner (5), the housing (3) and the drum (1) form an annular airtight space, which is the combustion chamber (4), and the top of the casing (3) has a smoke exhaust port (2). During work, the mixture of gas and air (6) passes through the metal fiber burner (5) and burns in the combustion chamber (4), and the infrared rays (7) produced by the combustion directly radiate to the drum (1), and the exhaust gas produced by the combustion (8) is discharged through the smoke outlet (2), and the tea leaves (9) roll with it in the drum (1) and absorb heat, thereby completing the greening process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com