A method for monitoring a manufacturing process in a textile plant

A technology of production process, textile mill, applied in monitoring production process, 1] The present invention relates to the former field as in the first claim, and can solve problems such as difficult management process and boundary conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

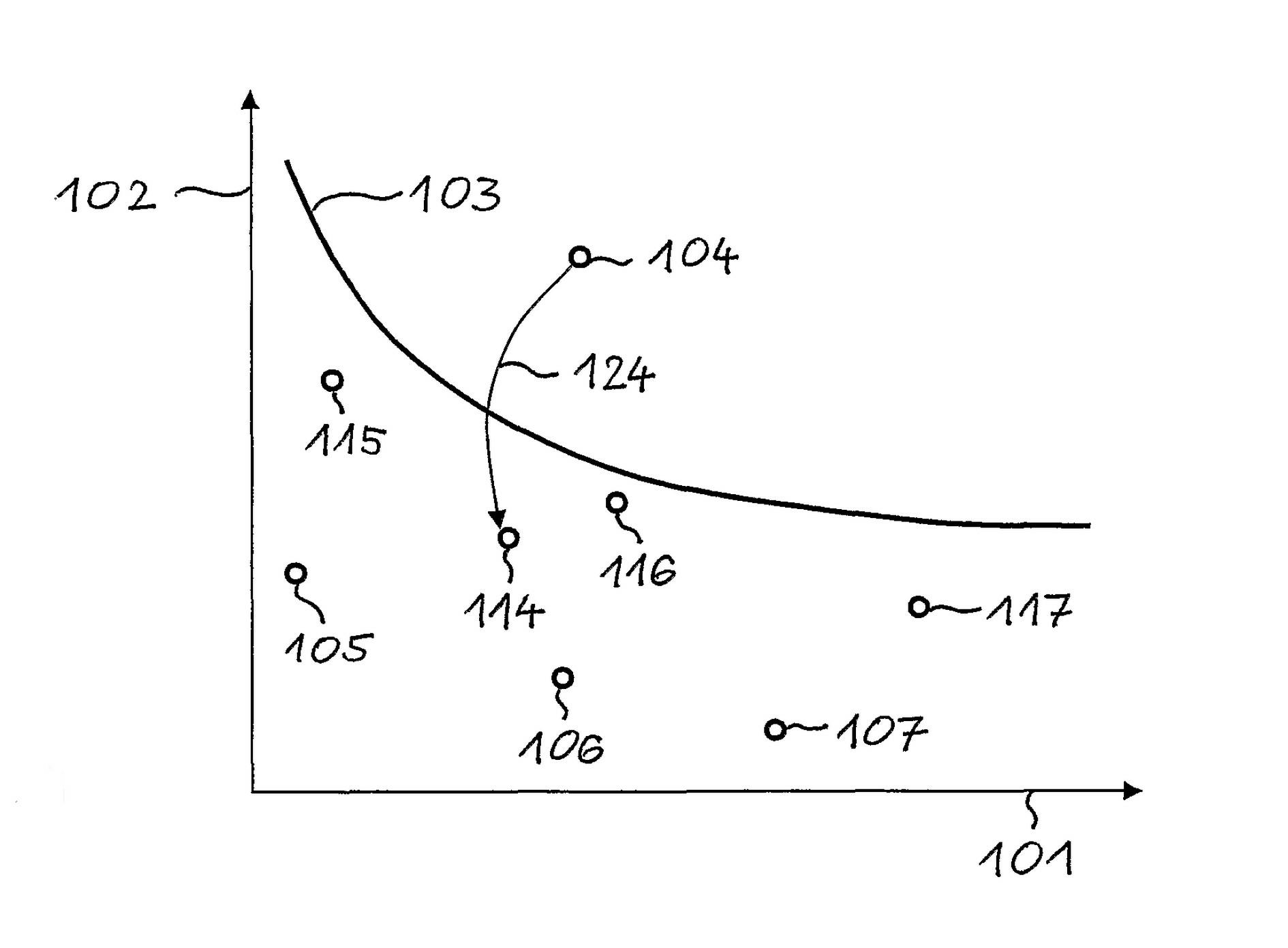

[0034] figure 1A possible index protocol for a textile structure such as a yarn is illustrated in the form of a predetermined quality curve 103 . A specific flaw parameter such as flaw size (eg diameter, or a product having a diameter and length) is input along the horizontal axis 101 and the frequency of each flaw parameter such as the number of flaws is entered along the vertical axis 102 . The individual yarns are represented by measurement points. The first yarn 104 represented by its measurement point lying above the curve 103 is considered to be non-compliant according to the defect parameter. The quality of the yarn can be increased to quality 114 when using a device such as a yarn clearer that can reduce defects. As indicated by arrow 124, the parameterization of the device is correlated, thereby removing a higher number of artifacts. However, this comes at the expense of productivity (the speed at which the yarn travels).

[0035] According to the prior art, prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com