Siphon type petroleum single well metering device for oilfield exploitation

A metering device, a siphon-type technology, applied in the field of suction single-well metering devices, can solve problems such as difficulty in timely detection, instability, and inaccurate measurement, and achieve accurate throughput calculation, short residence time, and easy and accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

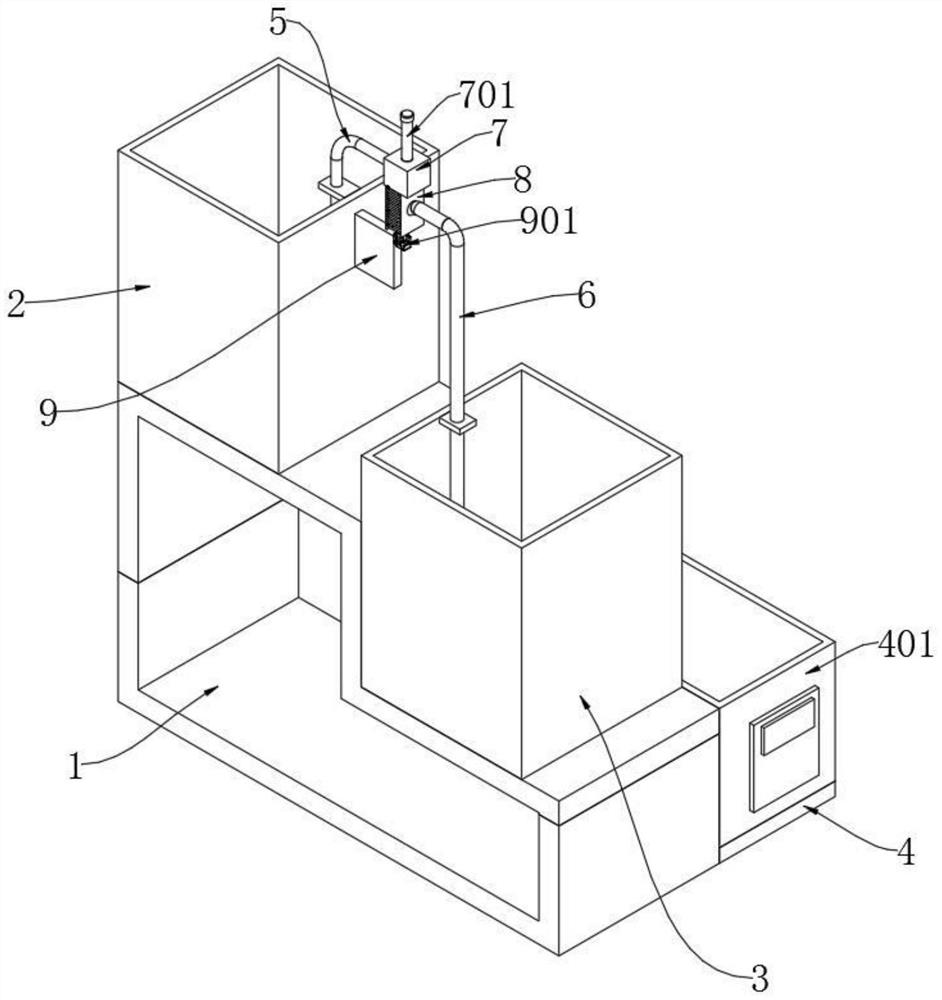

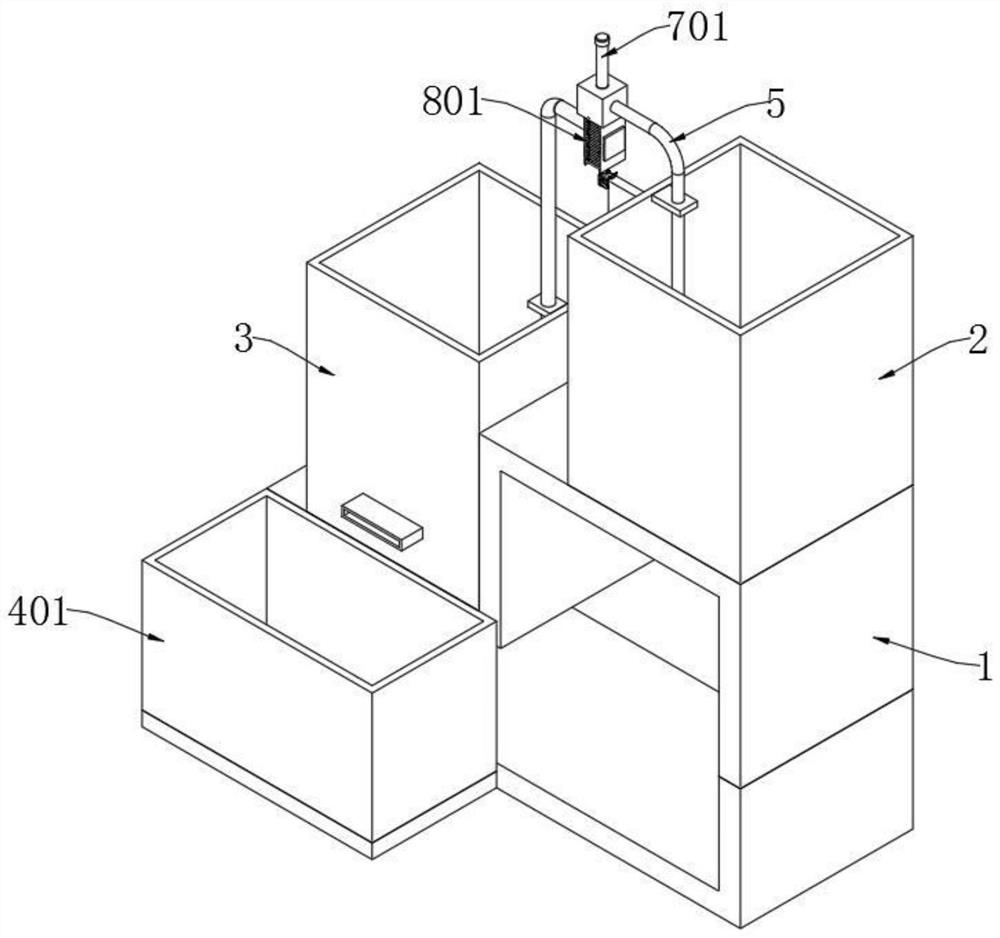

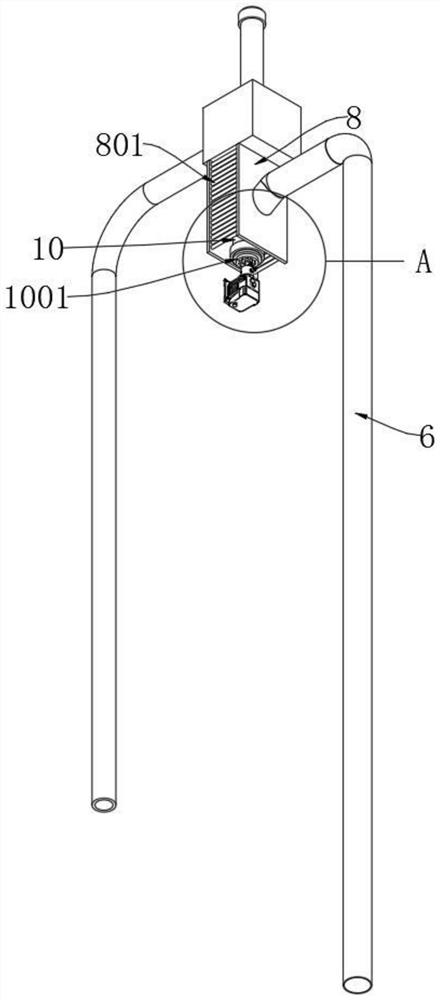

[0031] Example: please refer to Figure 1 to Figure 8 :

[0032] The invention proposes a siphon type oil single well metering device for oilfield exploitation, comprising: a support table 1; an upper tank body 2 is fixedly installed on the top of the left end of the support table 1; a lower tank body is fixedly installed on the top of the right end of the support table 1 3; the bottom of the rear end of the support table 1 is fixedly docked with a weighing table 4; the right end of the inner cavity of the upper tank body 2 is vertically installed with an upper siphon pipe 5; the left end of the inner cavity of the lower tank body 3 is vertically installed with a lower siphon pipe 6; The upper end of the siphon tube 5 is docked with a buffer box 7; the lower end of the buffer box 7 is fixedly docked with a measuring cylinder 10; the middle part of the measuring cylinder 10 is vertically rotated and installed with a measuring shaft 11; the lower end of the buffer box 7 outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com