Circular saw with anti-splinter device

An anti-splash, circular saw technology, applied in circular saws, auxiliary saw devices, woodworking safety devices, etc., can solve problems such as saw failures, reduce the anti-splash function of anti-splash structures, and achieve the effect of improving cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

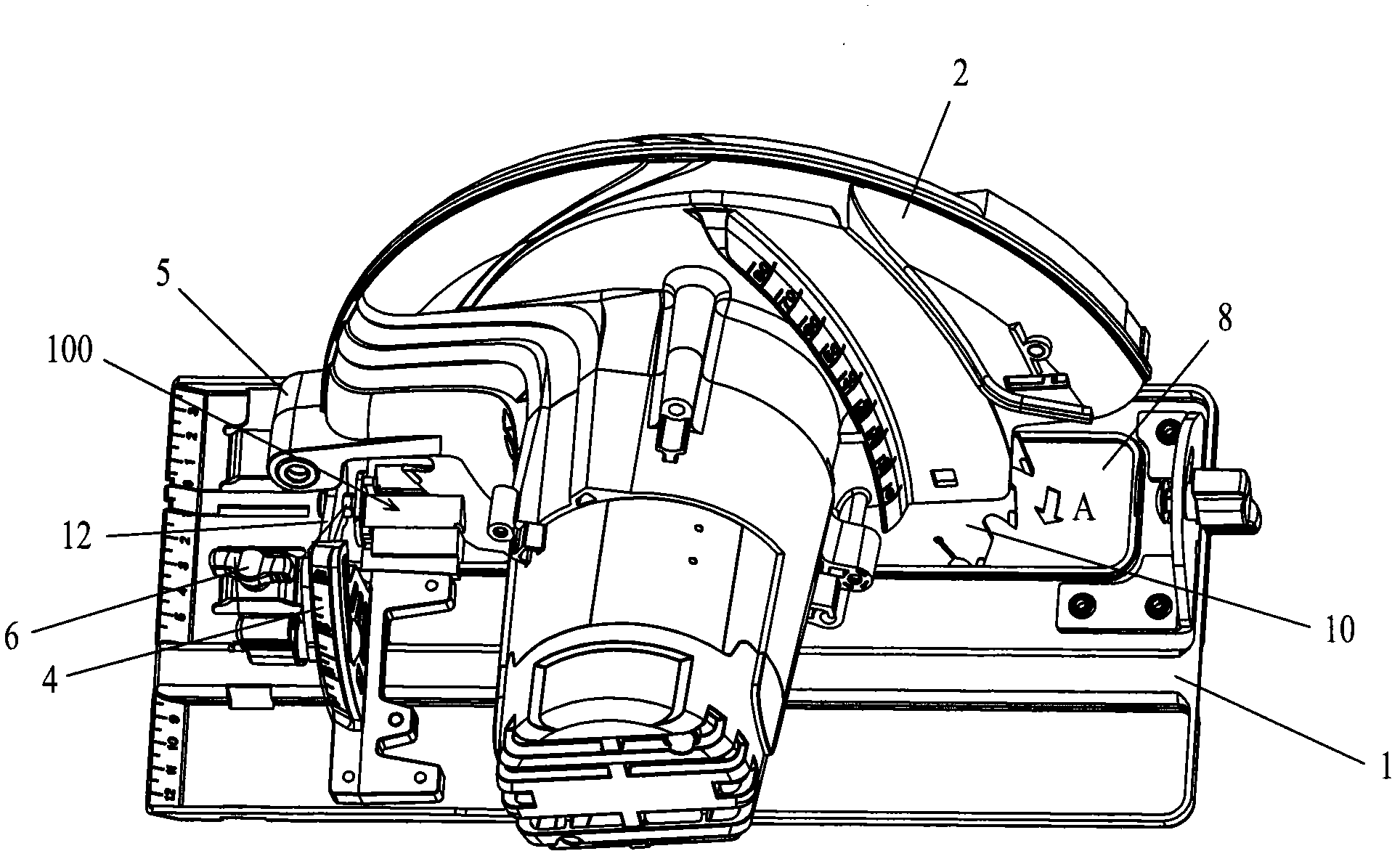

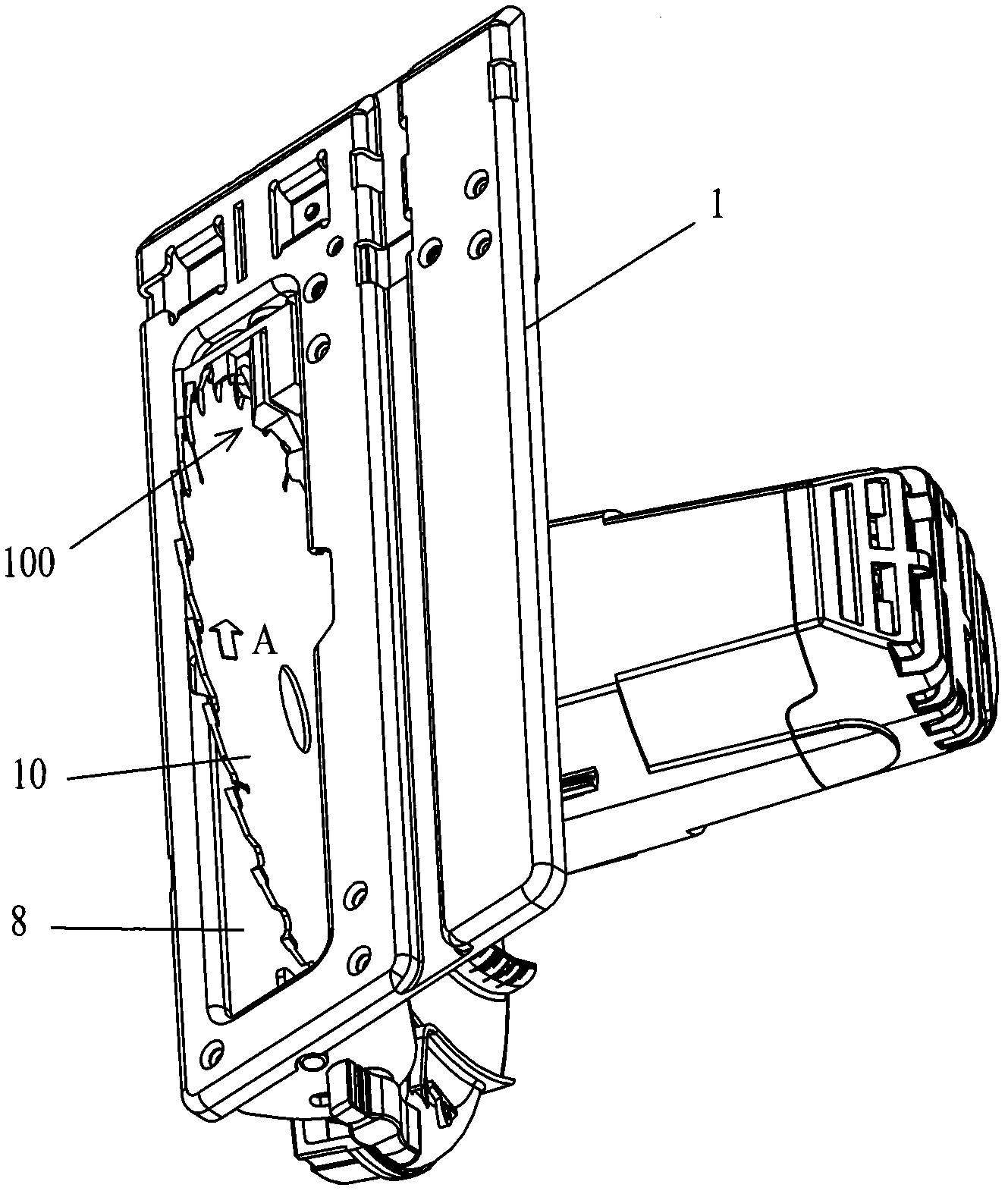

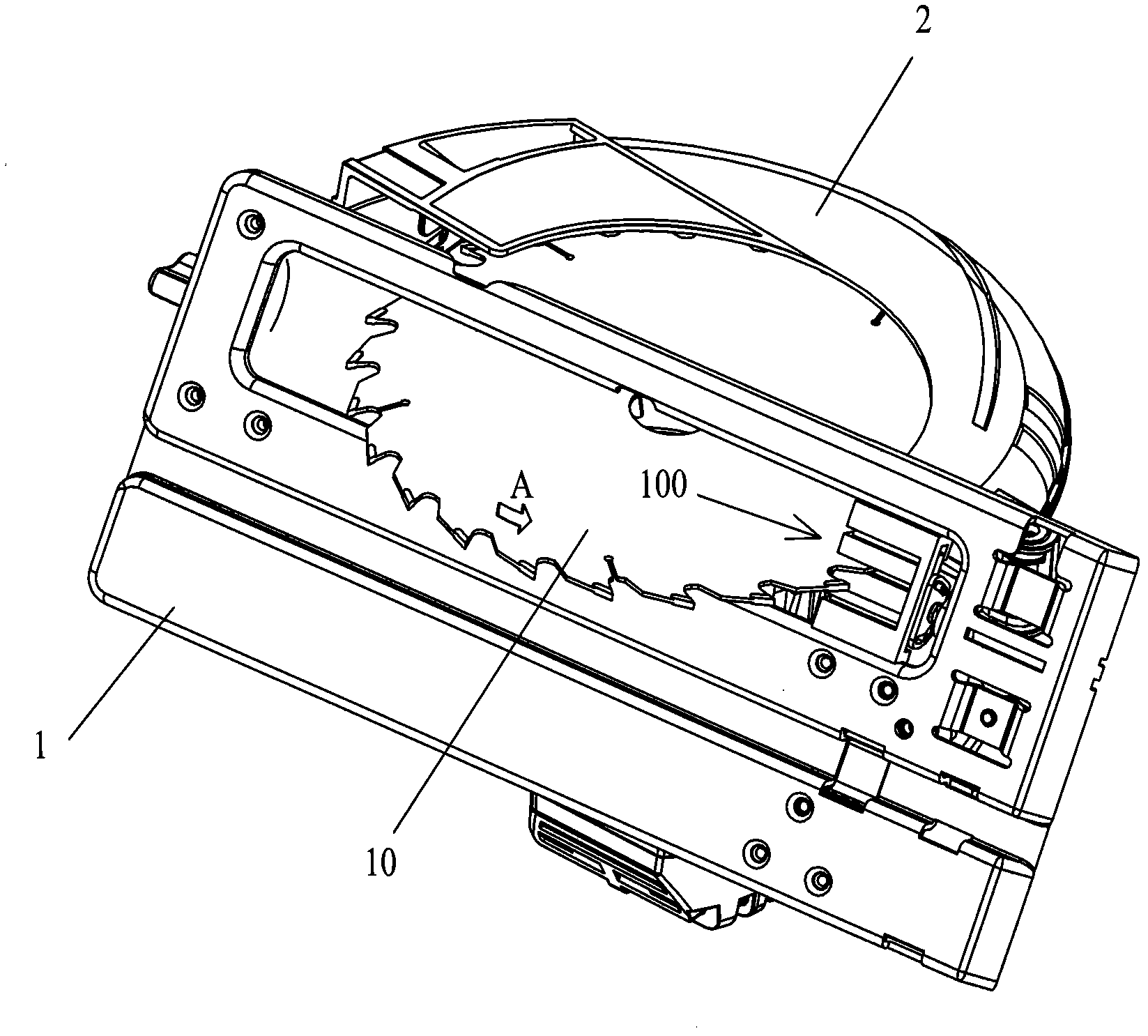

[0026] Preferred embodiments of a circular saw and its splash guard according to the present invention will now be described with reference to the accompanying drawings.

[0027] In this description, the term "workpiece" refers to any piece of cuttable material, such as wood, plastic material, glass, metal and the like.

[0028] Figure 1-3 A circular saw according to an embodiment of the invention is shown. The circular saw comprises a base plate 1 which has a substantially flat shape and thus defines a base plane. The substrate 1 will be placed on the surface of the workpiece for the cutting operation. Tilt bracket 12 is pivotally supported by base plate 1 , and housing 2 is pivotably supported by tilt bracket 12 via pivotable joint 5 . The housing 2 carries a rotary motor (not shown) and a circular saw blade 10 driven in rotation by the motor. The saw-out section of the saw blade 10 that is to cut into the workpiece extends through the elongated opening 8 formed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com