Method and equipment for utilizing waste heat of water drained after running water washing

A technology of washing water and running water, applied in lighting and heating equipment, heating methods, water heaters, etc., can solve the problems of low heat exchange efficiency, incomplete utilization, inclusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

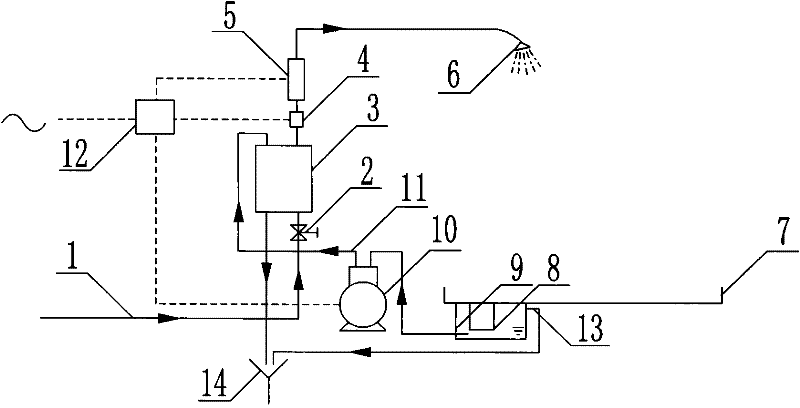

[0055] figure 1 It is a schematic diagram of a waste heat utilization system for shower drainage in the prior art. The water inlet valve 2, the water inlet side of the heat exchanger 3, the water flow switch 4, the heater 5, and the sprinkler head 6 are connected through the water inlet pipeline 1; In the water tank 9, the water collecting tank 9 is under the water receiving chassis 7; the water collecting tank 9, the drainage pump 10, and the drain side of the heat exchanger 3 are connected through the drain pipeline 11; the outlet of the heat exchanger 3 drain side is connected to the sewer 14; the water collecting tank 9 has The overflow port 13 is connected to the sewer 14; the heater 5 is an electric water heater, the motor of the water flow switch 4, the heater 5, and the drainage pump 10 is connected with the controller 12, and the motor speed of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com