Wind power generation mechanism and electric motor car provided with same

A generator and transmission mechanism technology, applied in the field of electric vehicles, can solve the problems of insufficient power consumption, low utilization rate of wind energy, general energy storage effect, etc., and achieve the effect of improving driving mileage and range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

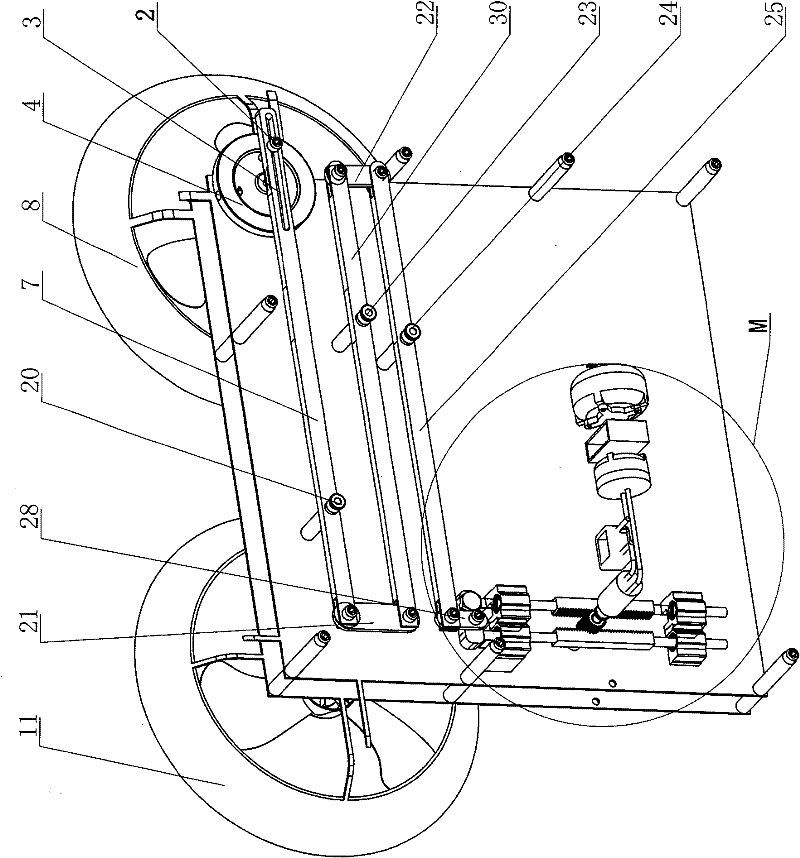

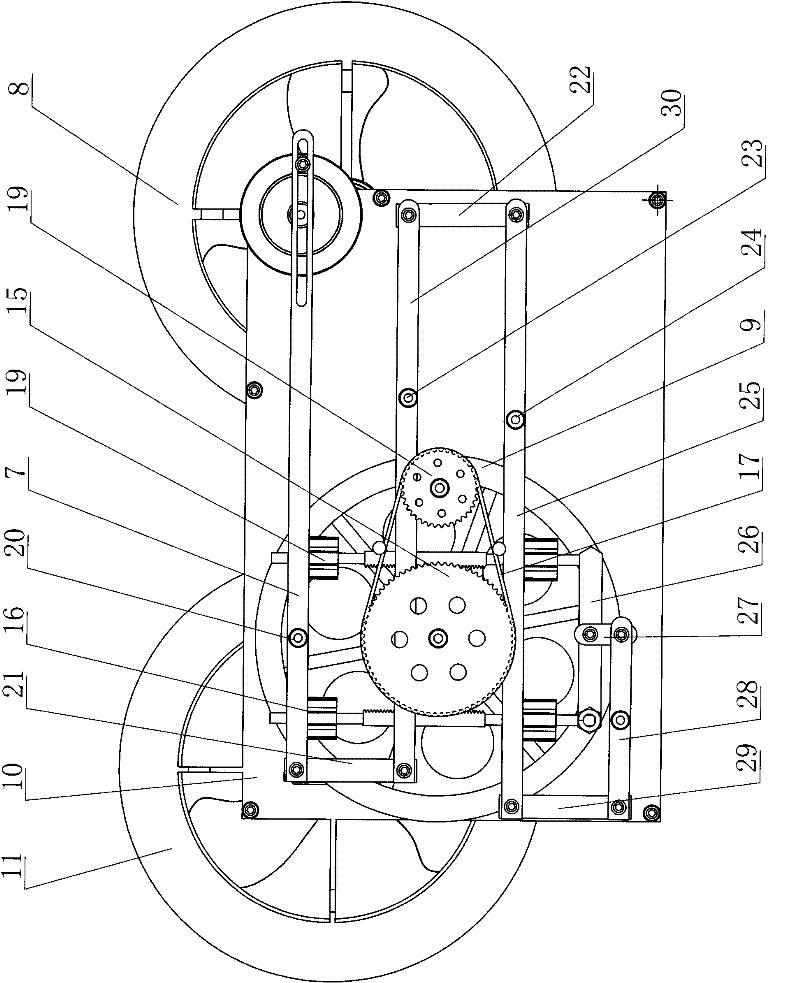

[0020] Embodiment one: refer to Figure 1 to Figure 5, this kind of wind power generation mechanism includes a main wind wheel 8, a rotating shaft 39 and a body 10, the main wind wheel 8 is mounted on the body 10 through the rotating shaft 39, and four swingable levers are installed on the body 10 7, 30, 25, 28, each lever is swingably mounted on the body 10 around the fulcrums 20, 23, 24, 34 respectively, and the head and tail of each lever are movably connected in turn; Connect, the two ends of connecting rod 21 are respectively hinged with the tail of the first lever 7 and the head of the second lever 30, through the connecting rod 22, the two ends of the connecting rod 22 are respectively connected with the tail of the second lever 30 and the third The head of the bar lever 25 is hinged, after the afterbody of wherein the third lever 25 is hinged with the connecting rod 29, the connecting rod 29 is hinged with the head of the fourth lever 28 again, and the afterbody of the...

Embodiment 2

[0022] Embodiment two: refer to Figure 6 ~ Figure 7 , in the present embodiment, its lever is three, carries out head-to-tail movable connection respectively by connecting rod 21,22, and wherein connecting rod 28 is used as the push rod of air cylinder, but one end of the first lever 7 is hinged with connecting rod 56 and is connected with rotating disk 4 Eccentrically connected, its transmission mechanism includes a cylinder 57, a pneumatic motor 58, the push rod 28 of the cylinder 57 is connected to the tail end of the third lever 25, and the air outlet of the cylinder 57 is connected to the pneumatic motor 58 through the air pipe 60 , a one-way valve 59 is arranged on the air pipe 60. When the one-way valve 59 is closed, the purpose of gas storage is achieved; The transmission 55 is connected to the rotating shaft of the generator 1 . When the main wind wheel 8 and the auxiliary wind wheel 11 are subjected to the wind force, the turntable 4 is rotated by the transmission ...

Embodiment 3

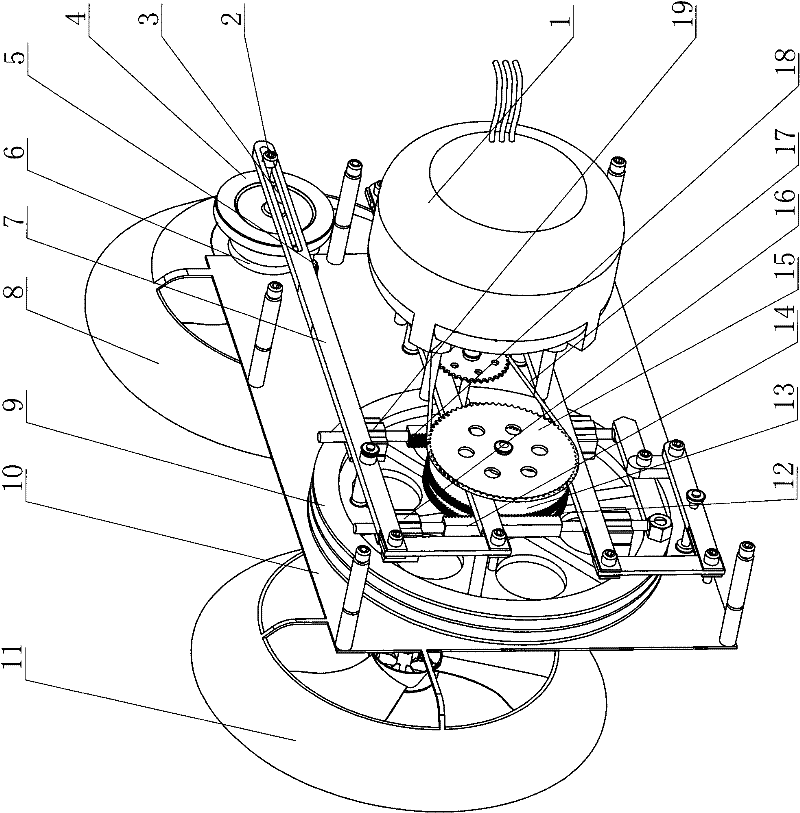

[0023] Embodiment three: refer to Figure 8 ~ Figure 11 The difference between this embodiment and the first embodiment is that there is only one lever, and the transmission mechanism includes a first gear 43, a second gear 41, a first sprocket 44, a second sprocket 47, a first pinion 45, a first sprocket The second pinion 40 and the half-moon wheel 46, the first gear 43, the first sprocket 44 and the first pinion 45 are coaxially installed on the first rotating shaft 63, wherein the first sprocket 44 is integrated with the first pinion 45 set, and the first gear 43 and the second gear 41 are respectively installed on the first rotating shaft 63 and the second rotating shaft 64 through the one-way bearing, wherein the one-way bearing on the first gear 43 and the one-way bearing on the second gear 41 The bearing direction is opposite, the second gear 41 and the second sprocket 47 are coaxially installed on the second rotating shaft 64, the first sprocket 44 and the second sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com