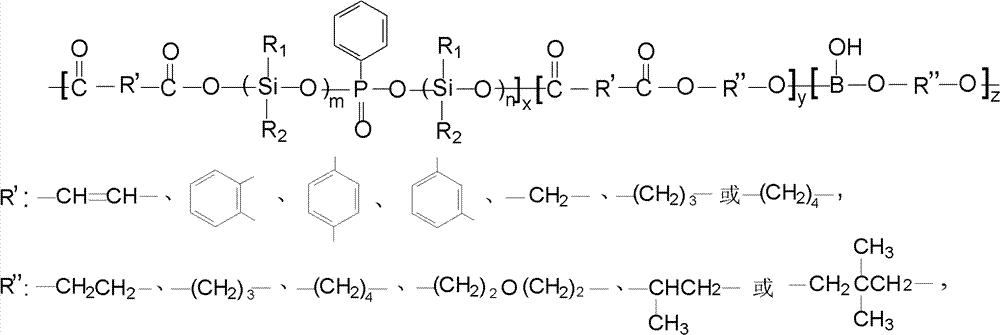

Transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyester and preparation method thereof

An unsaturated and reactive technology, applied in the field of transparent reactive phosphorus silicon boron flame retardant unsaturated polyester and its preparation, to achieve the effect of good thermal bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

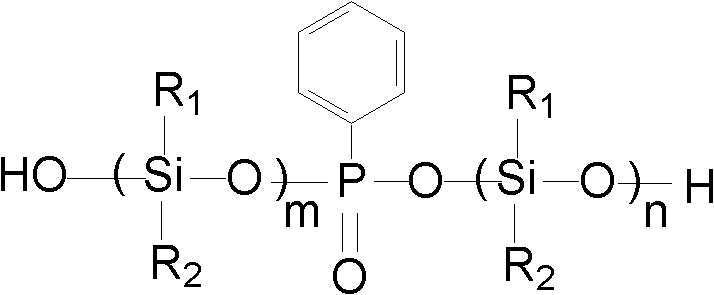

Method used

Image

Examples

Embodiment 1

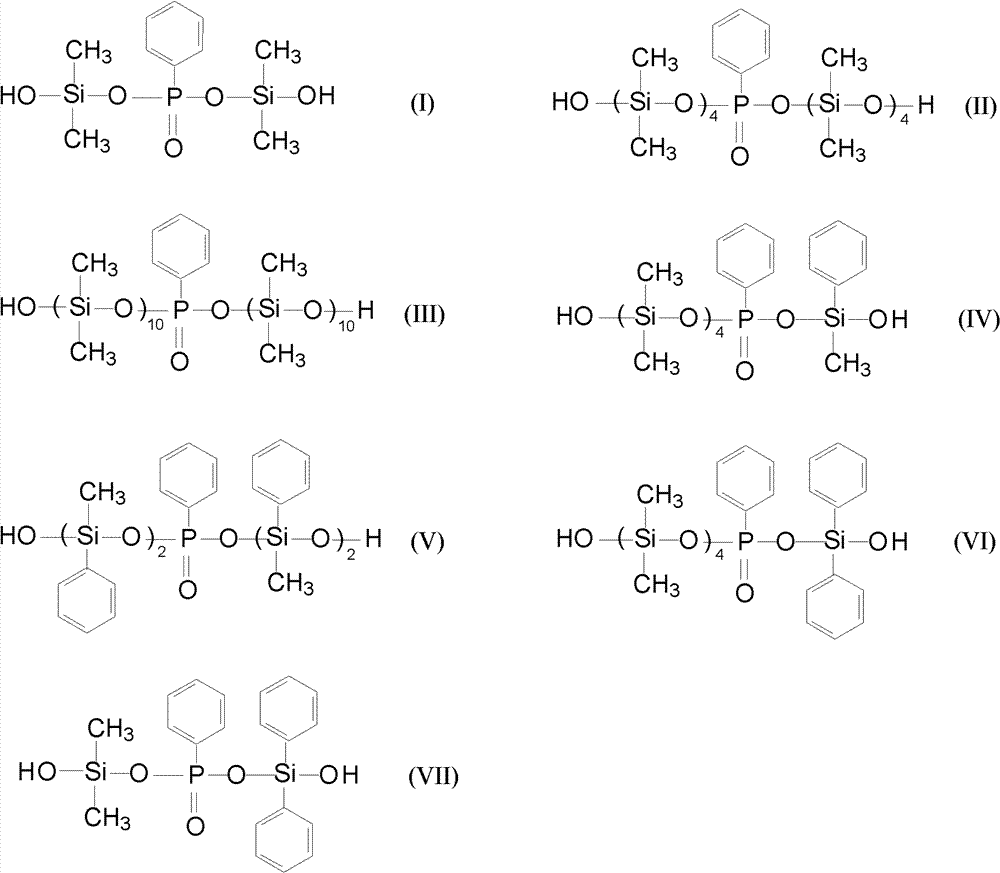

[0025] Add 2 mol of dimethylsilanediol to a 2000ml four-necked flask connected with an HCl absorption device, add 1 mol of phenylphosphoryl dichloride dropwise under stirring, react at 30°C for 4 hours after dropping, and raise the temperature to 100-120°C Heated for 2 hours to obtain a phosphorus-containing silicon monomer, which is denoted as a phosphorus-containing silicon monomer (I);

[0026] Get 0.3mol above-mentioned synthetic phosphorus-containing silicon monomer (I), 0.9mol propylene glycol, 0.5mol maleic anhydride, 0.3mol phthalic anhydride, 0.2mol boric acid and place in 250ml four-necked flask, N 2 Stir under air protection, heat up, raise the temperature to 150-160°C, keep the temperature for 2 hours, further raise the temperature to 180-200°C, react until the acid value of the system remains basically unchanged, stop heating, and obtain an unsaturated polyester pre-prepared polyester containing phosphorus, boron and silicon elements Polymer; cooling to 100°C, add...

Embodiment 2

[0028] Add 2mol Under stirring, add 1 mol of phenylphosphoryl dichloride dropwise, react at 40°C for 6 hours after dropping, heat up to 120-140°C for 3 hours, and obtain a colorless phosphorus-containing silicon monomer, which is recorded as phosphorus-containing silicon monomer ( II);

[0029] Get 0.13mol above-mentioned synthetic phosphorus-containing silicon monomer (II), 0.3mol ethylene glycol, 0.6mol propylene glycol, 0.55mol maleic anhydride, 0.15mol maleic acid, 0.14mol isophthalic anhydride, 0.16mol boric acid in 250ml four-neck flask, N 2 Stir under air protection, heat up, heat up to 150-160°C, react at constant temperature for 2 hours, further raise the temperature to 190-210°C, react until the acid value of the system remains basically unchanged, stop heating, and obtain unsaturated polyester containing phosphorus, boron, and silicon elements Prepolymer; cool to 120°C, add styrene; continue to cool to 50°C, add hydroquinone inhibitor and dicumyl peroxide initiat...

Embodiment 3

[0031] Add 2mol Under stirring, add 1 mol of phenylphosphoryl dichloride dropwise, react at 60°C for 5 hours after dropping, heat up to 140-150°C for 2 hours, and obtain a colorless phosphorus-containing silicon monomer, which is recorded as phosphorus-containing silicon monomer ( III);

[0032] Get 0.15mol of the above-mentioned synthetic phosphorus-containing silicon monomer (III), 0.5mol neopentyl glycol, 0.6mol propylene glycol, 0.4mol maleic anhydride, 0.2mol fumaric anhydride, 0.2mol isophthalic acid, and 0.2mol boric acid in 250ml four-neck flask, N 2 Stir under air protection, raise the temperature to 150-160°C, keep the temperature constant for 2 hours, further raise the temperature to 185-205°C, react until the acid value of the system remains basically unchanged, stop heating, and obtain an unsaturated polyester prepolymer containing phosphorus, boron, and silicon elements ; Cool to 110°C, add vinyl toluene; continue to cool to 40°C, add hydroquinone inhibitor an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com