Automatic blowing mechanism on mold

A blowing mechanism and automatic technology, applied in the field of automatic blowing mechanism and product blowing mechanism, can solve the problem that ordinary molds cannot be formed, and achieve the effect of simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

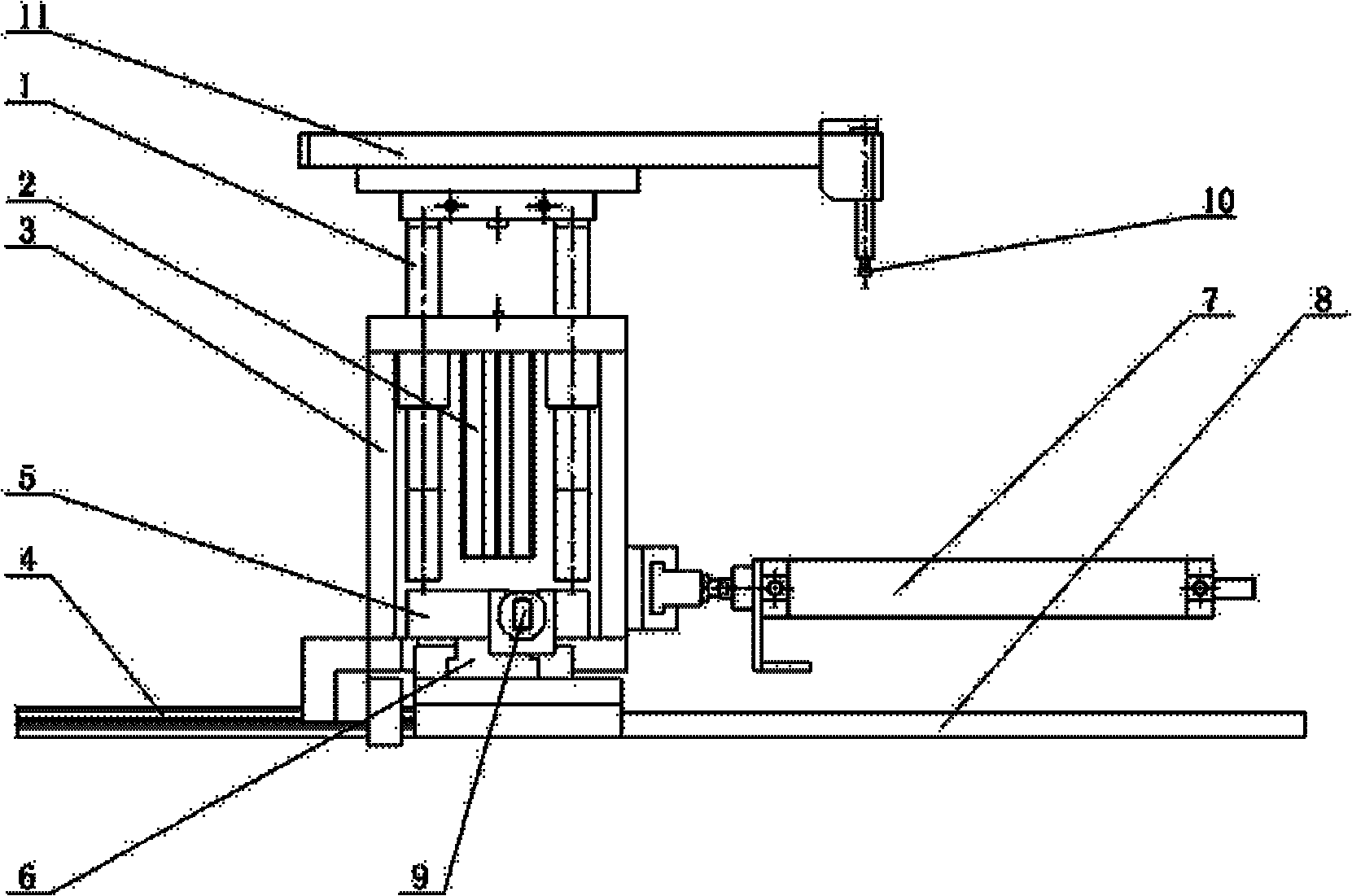

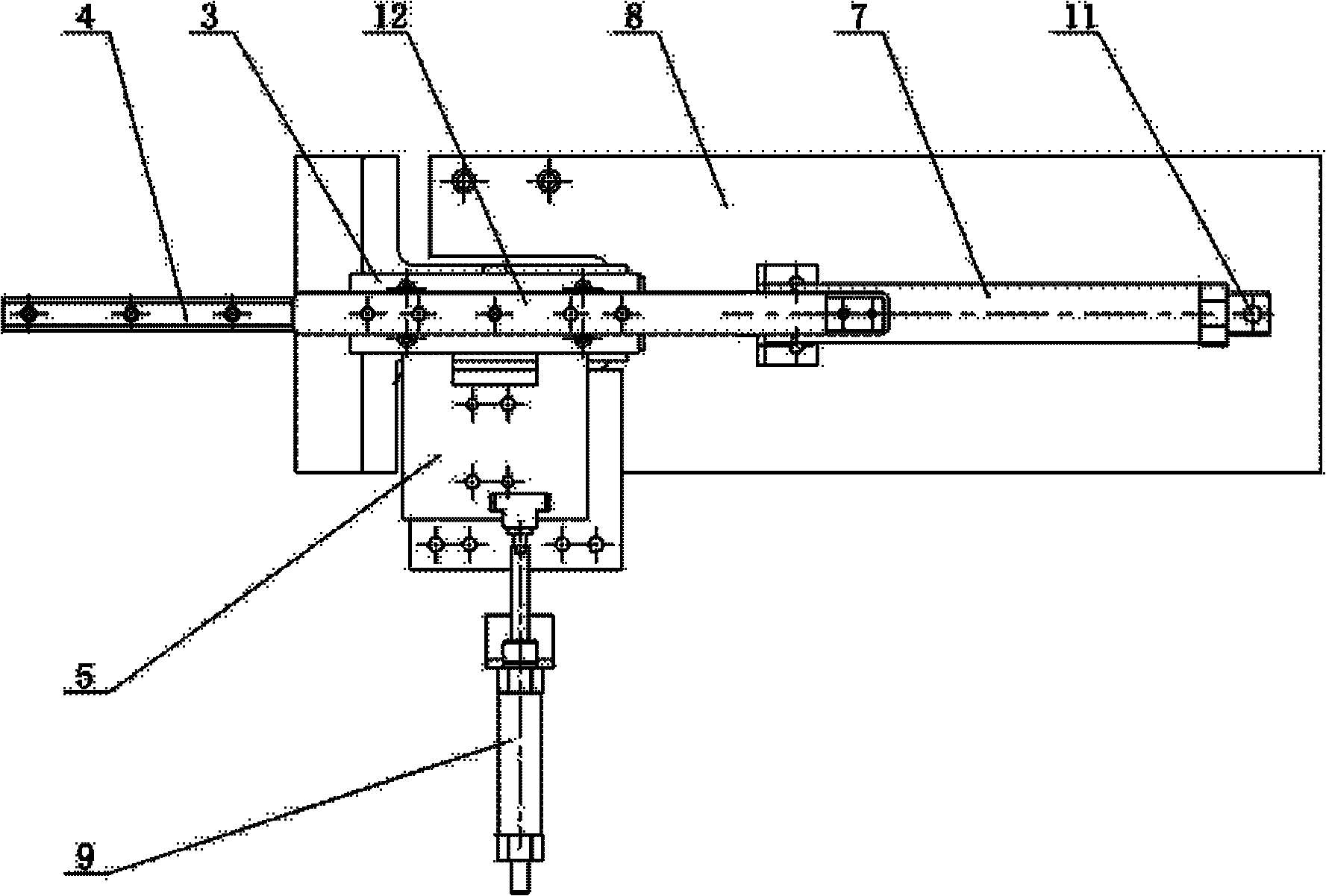

[0013] The present invention will be further described below in conjunction with specific drawings.

[0014] like Figure 1 to Figure 4 Shown: The automatic blowing mechanism on the mold includes guide rail 1, first cylinder 2, support frame 3, first guide rail 4, height limit block 5, second guide rail 6, second cylinder 7, lateral limit block 8. The third air cylinder 9, air blowing needle 10, trachea joint 11, air needle fixing rod 12, etc.

[0015] The present invention includes a support frame 3, a hole and a first cylinder 2 are arranged above the support frame 3, and a guide rod 1 is arranged in the hole, and the guide rod 1 can be driven by the piston rod of the first cylinder 2 Slide up and down in the hole; an air needle fixing rod 12 is erected above the guide slide rod 1, and one end of the air needle fixing rod 12 is provided with an air blowing needle 10, and the air blowing needle 10 is connected with the trachea joint 11;

[0016] A first guide rail 4 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com